Screw pump driving device

A technology of driving device and screw pump, which is applied in the direction of wellbore/well valve device, drill pipe, mining fluid, etc. It can solve the problems of hurting people, low pressure, square clips loosening and flying out, etc., so as to improve the service life and prevent The effect of pipeline backflow, avoiding economic loss and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

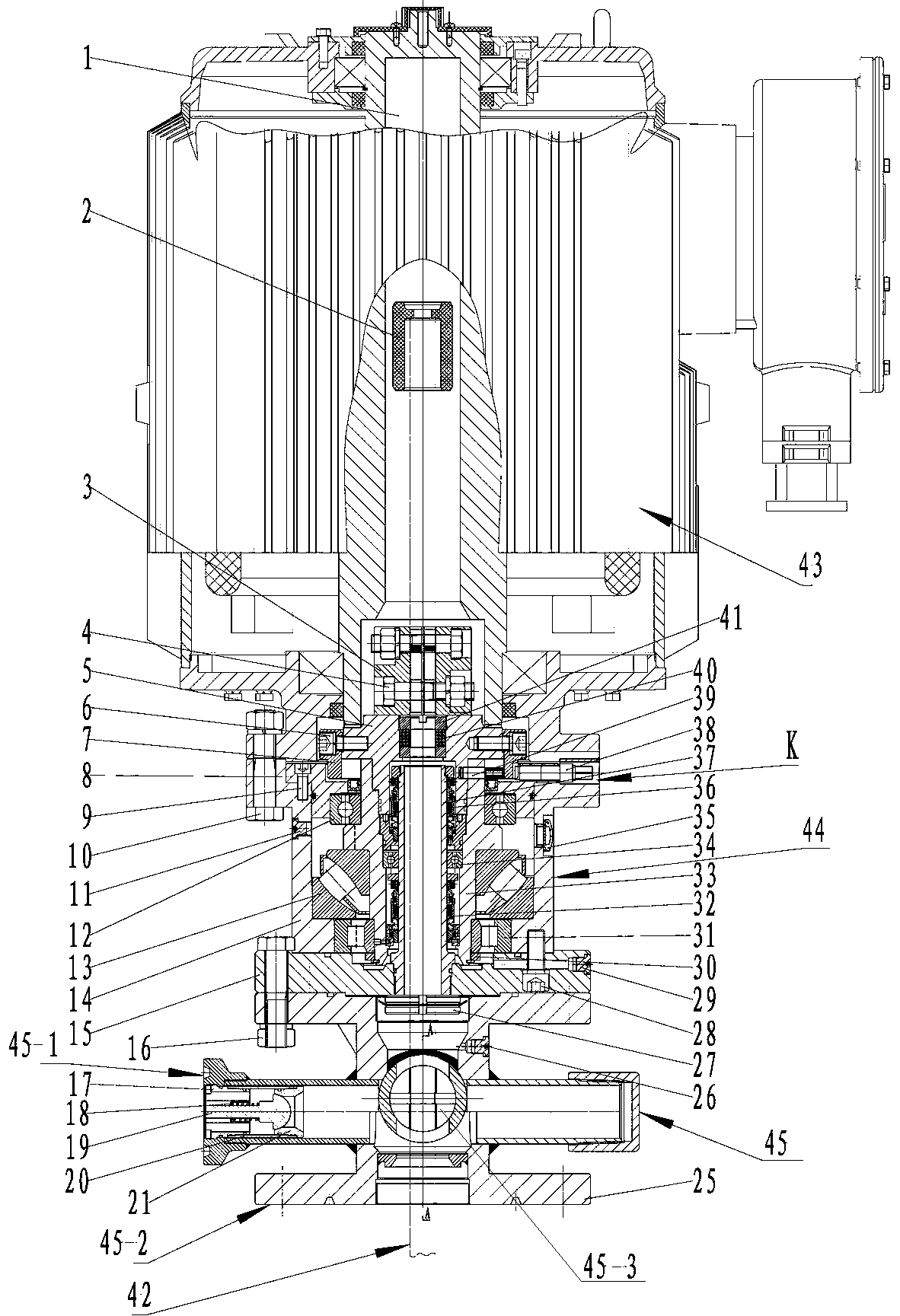

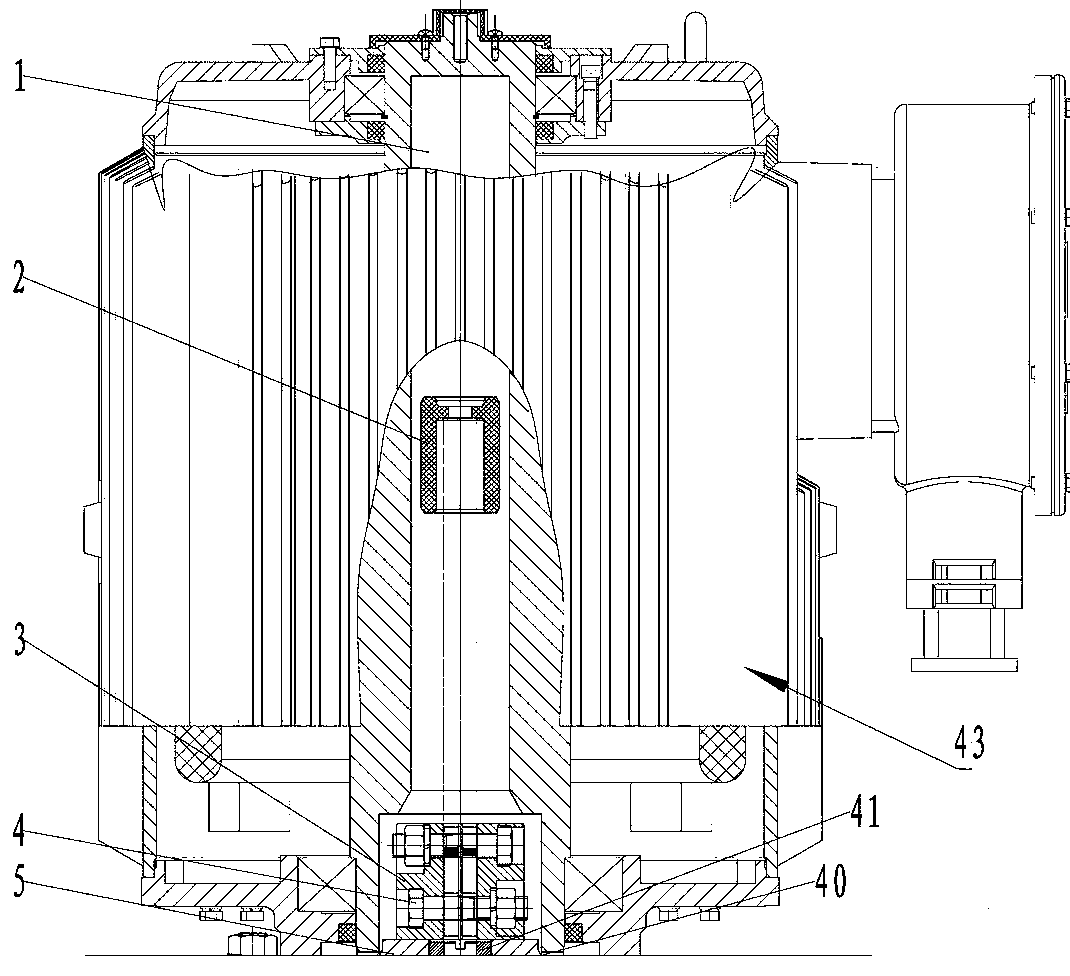

[0037] See figure 1 - Fig. 13, the specific structure of the present embodiment is, screw pump driving device, comprises drive motor 43, drive base 44, blowout preventer 45, sucker rod polished rod 42; Drive motor 43 sits on the upper end of drive base 44 and Fix by bolt nut II10,

[0038] The drive motor 43 includes a hollow motor shaft 1, a rubber tube sheath 2, and a square clip 3. The square clip 3 is symmetrical in two halves. The lower end of the square clip 3 has a T-shaped connection groove 3-1. The nut I4 clamps and fixes the polished rod 42 of the sucker rod; the rubber sleeve sheath 2 is set on the upper end of the polished rod 42 of the sucker rod;

[0039]The drive base 44 includes a central tube 37, a main shaft 33, a central tube bearing 34, a cap head 5, a packing seal 40, a packing pressure cap 41, a brake flange 7, a brake top screw 38, and an upper mechanical seal 36 , lower mechanical seal 32, bearing cover 8, cylindrical pin 39, upper righting bearing 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com