Preparation method of nano-particle@minisize metal organic frame material

A technology of metal-organic frameworks and nanoparticles, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., to achieve good versatility, strong applicability, and the effect of preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Synthesis of Pt nanoparticles

[0029] Aqueous solution of chloroplatinic acid (6mM, 20ml) and polyvinylpyrrolidone (0.018mmol) were mixed, then methanol was added and the volume was adjusted to 200 ml, after the polyvinylpyrrolidone was stirred and dissolved, the mixed solution was transferred to a 250 ml round-bottomed flask, and placed Reflux and react in an oil bath at 70°C for 3 hours, spin-evaporate the obtained product, precipitate and centrifuge with acetone, and finally wash with chloroform and n-hexane for 10 times, disperse in methanol for later use, and the particle size is about 3nm.

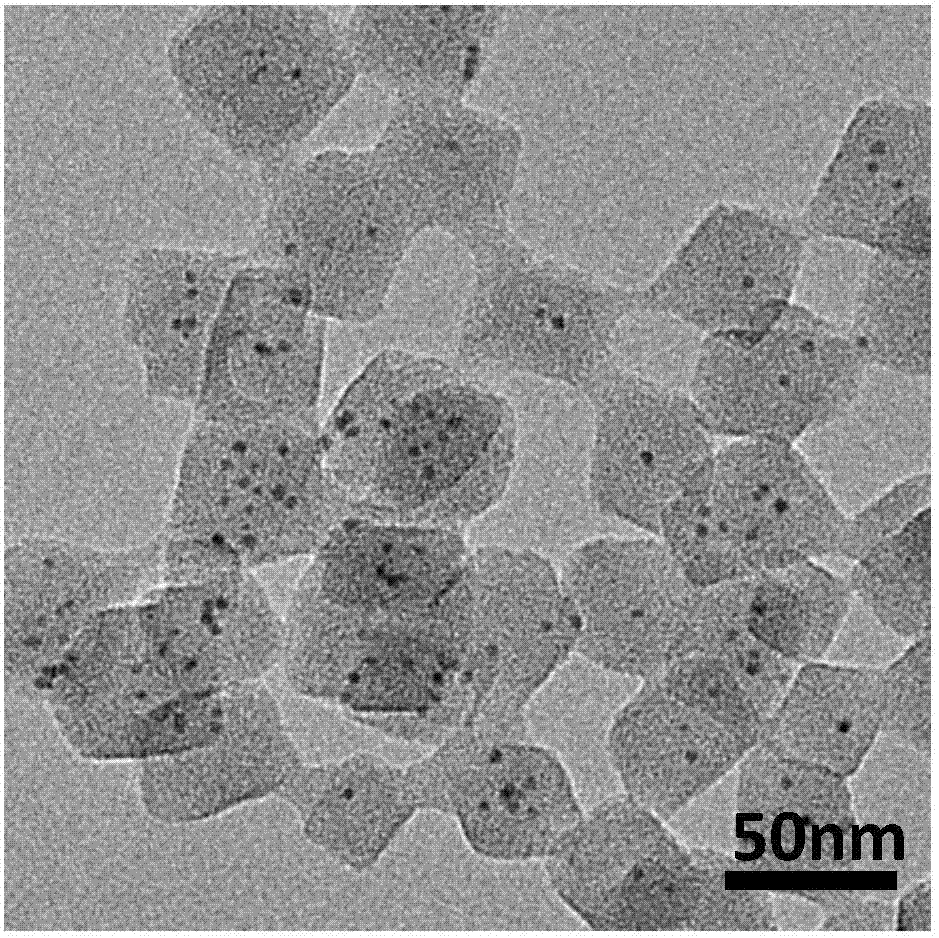

[0030] 2) Synthesis of Pt@nano-UiO-66 using a small molecule acetic acid regulator

[0031] 0.005mmol of Pt nanoparticles modified by polyvinylpyrrolidone synthesized in step 1), 0.14mmol of zirconium tetrachloride, 0.14mmol of terephthalic acid and 0.4ml of acetic acid were mixed, and N, N dimethylformamide was added to constant volume. 10ml, ultrasonic 1min fully dissol...

Embodiment 2

[0034] 1) The synthesis of Pt nanoparticles modified by polyvinylpyrrolidone is the same as in Example 1.

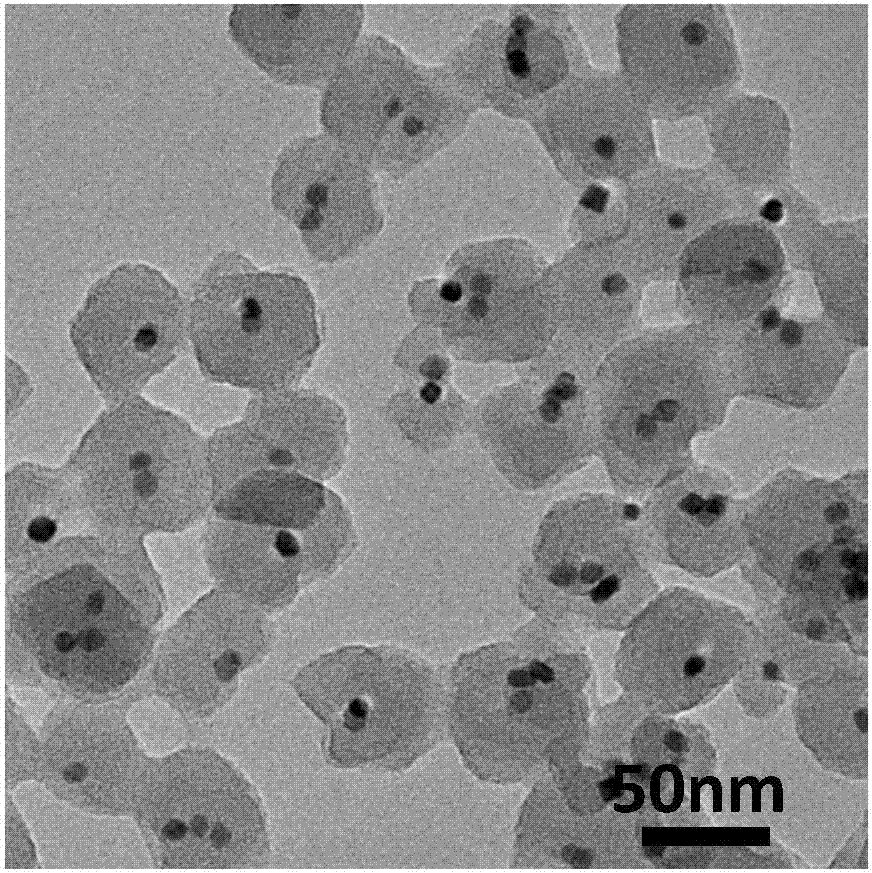

[0035] 2) Synthesis of Pt@nano-UiO-66-NH using a small molecule acetic acid regulator 2

[0036] Mix 0.005 mmol of Pt nanoparticles modified with polyvinylpyrrolidone, 0.14 mmol of zirconium tetrachloride, 0.14 mmol of aminoterephthalic acid and 0.5 ml of acetic acid, and add N,N dimethylformamide to make the total volume 10 ml , sonicated for 1 min and fully dissolved, transferred to a 20 ml isotope bottle and placed in a 120 °C oven for solvothermal reaction for 36 h, the obtained product was centrifuged, washed three times with N, N dimethylformamide and ethanol, and dried , that is, Pt@nano-UiO-66-NH 2 , the resulting size is about 25 nm.

[0037] The characterization diagram of the product is shown in 5-6, Figure 5 It is the TEM image of Pt@nano-UiO-66-NH2, Figure 6 It is the powder diffraction pattern of Pt@nano-UiO-66-NH2.

Embodiment 3

[0039] 1) The synthesis of Pt nanoparticles modified by polyvinylpyrrolidone is the same as in Example 1.

[0040] 2) Synthesis of Pt@nano-801 using acetic acid regulator

[0041] Mix 0.005 mmol of Pt nanoparticles modified with polyvinylpyrrolidone, 0.14 mmol of zirconium tetrachloride, 0.14 mmol of fumaric acid and 0.5 ml of acetic acid, and add N, N dimethylformamide to make the total volume 10 ml , sonicated for 1min and fully dissolved, transferred to a 20ml isotope bottle and placed in a 120°C oven for solvothermal reaction for 24h, the obtained product was centrifuged, washed three times with N,N dimethylformamide and ethanol, and dried , that is, Pt@nano-801, the resulting size is about 30nm.

[0042] The characterization diagram of the product is shown in 7-8, Figure 7 It is the transmission electron microscope picture of Pt@nano-801, Figure 8 It is the powder diffraction pattern of Pt@nano-801.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com