A kind of preparation method of pure natural edible acorn powder

A kind of acorn powder, a pure natural technology, applied in the field of food processing, can solve the problems of acorn tannin loss, low raw material utilization rate, poor starch quality, etc., and achieve the effect of less impurities, high utilization rate and light astringency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

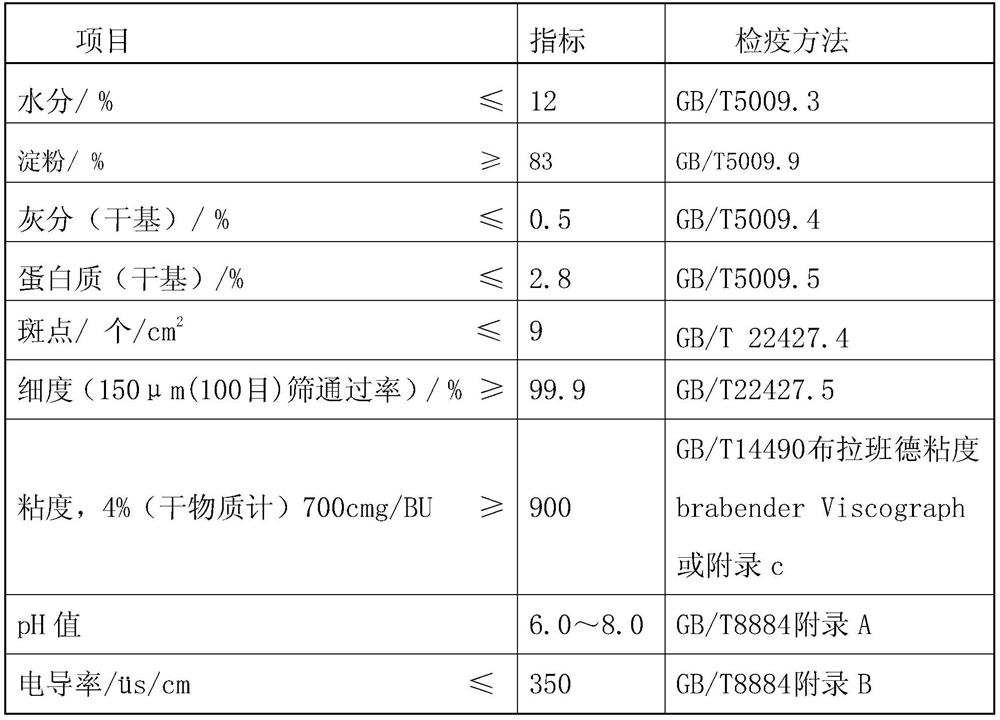

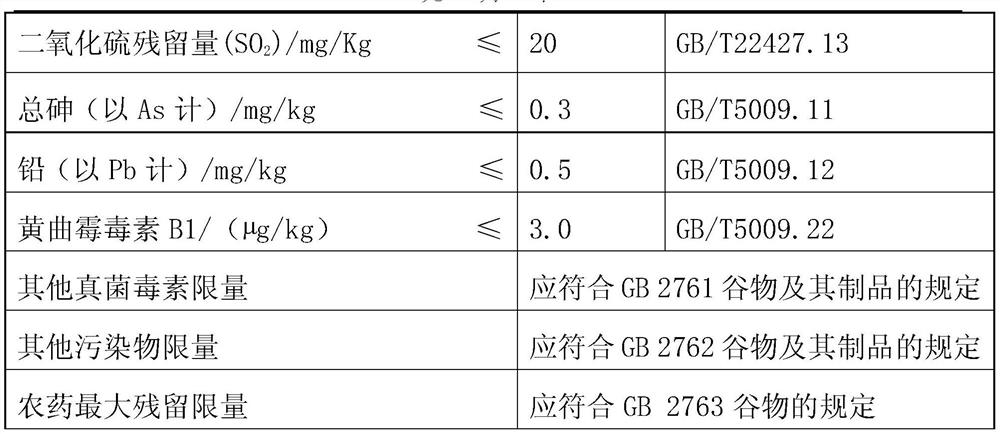

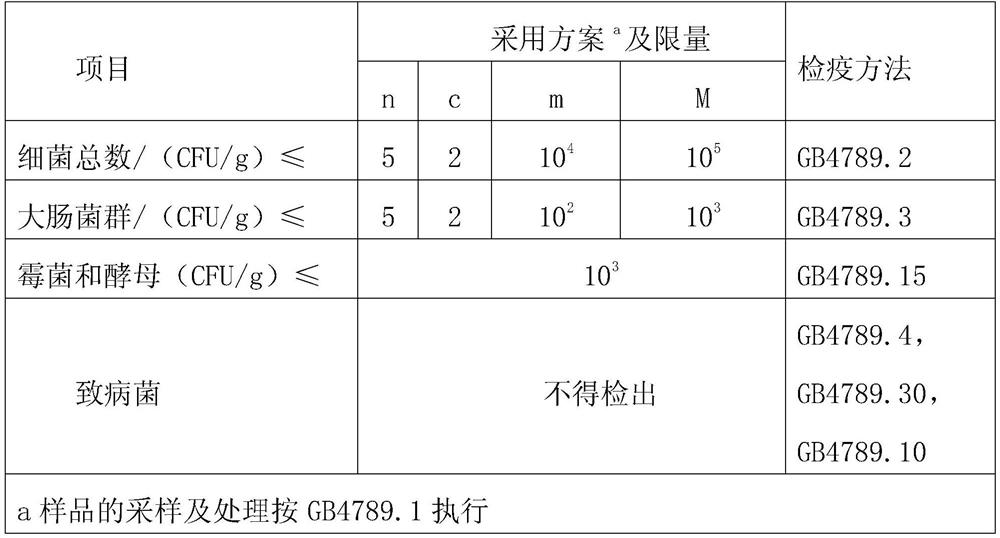

Image

Examples

Embodiment 1

[0012] a. Recovery of tannins: select dry acorn kernels that are clean and free from mold and insect damage, crush them with a coarse grinder with a 25-mesh sieve to obtain coarse particles of acorn kernels, put them into an ultrasonic multifunctional extraction tank, and separate them with acorn kernels. The edible alcohol of 5 times, 3 times, and 3 times the mass of the coarse grains of the kernels is leached 3 times under the action of stirring and ultrasonic waves, the temperature of each leaching is 55 ° C, the leaching time is 90 minutes, and then the filter cloth is pressed and filtered to recover and merged 3 times Put the alcohol extract into a vacuum concentration tank at 75°C and 0.085 MPa to concentrate and recover the alcohol in a vacuum to obtain acorn kernel crude tannin, which can be used as industrial tannin, and the recovered alcohol can be reused;

[0013] b. Recovery of residual alcohol: the coarse acorn kernel particles after tannin extraction are placed in...

Embodiment 2

[0016] a. Recovery of tannins: select dry acorn kernels that are clean and free from mold and insect damage, and crush them with a coarse grinder with a 50-mesh sieve to obtain coarse particles of acorn kernels, put them into an ultrasonic multifunctional extraction tank, and use them separately The edible alcohol with 5 times, 3 times and 3 times the mass of acorn kernel particles was leached 3 times under the action of stirring and ultrasonic waves, each time the leaching temperature was 60°C, and the leaching time was 60 minutes, then the filter cloth was pressed, filtered and recovered and merged 3 times Put the alcohol extraction solution into a vacuum concentration tank at 65°C and 0.09 MPa to concentrate and recover the alcohol in a vacuum to obtain acorn kernel crude tannin, which can be used as industrial tannin, and the recovered alcohol can be reused;

[0017] b. Recovery of residual alcohol: the coarse particles of acorn kernels after leaching tannin are placed in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com