Method for promoting anaerobic fermentation of needle mushroom feet for producing biogas by adopting activated carbon

An anaerobic fermentation and activated carbon technology, which is applied in fermentation, biological sludge treatment, waste fuel, etc., can solve the problems of poor anaerobic fermentation performance, low biogas production, and long time required to achieve improved gas production performance , favorable environmental resources and increased gas production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

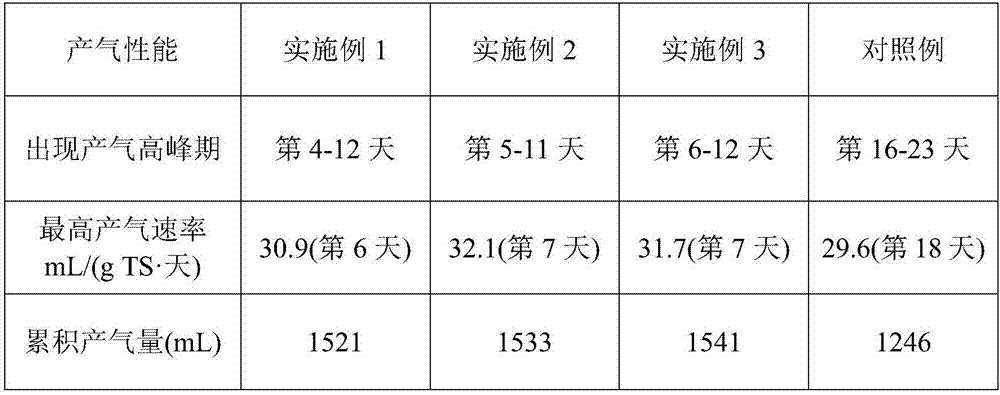

Examples

Embodiment 1

[0021] (1) Preparation of fermentation raw materials:

[0022] Select fresh Flammulina velutipes from the market, and collect the mushroom feet of Flammulina velutipes as raw materials for anaerobic fermentation. The fermentation inoculum was obtained from the activated sludge in the anaerobic section of a sewage treatment plant in Chengdu. The additive activated carbon was purchased from the market.

[0023] Total solids content is 9.81% (be after fresh Flammulina velutipes is dried at 105 DEG C) in the foot of Flammulina velutipes, and total volatile organic matter VS content is 7.71%; Total dry matter content is 2.7% in the inoculum activated sludge, The total volatile organic compound VS content was 1.1%.

[0024] (2) Anaerobic fermentation treatment:

[0025] (1) After adopting pulverizer to pulverize the mushroom feet of Flammulina velutipes, add the sodium hydroxide solution of mass concentration 1% wherein, the liquid-solid ratio of described sodium hydroxide soluti...

Embodiment 2

[0028] (1) Fermentation raw material selects the raw material among the embodiment 1.

[0029] (2) Anaerobic fermentation treatment:

[0030] (1) After adopting pulverizer to pulverize the feet of Flammulina velutipes, add the sodium hydroxide solution of mass concentration 1% wherein, the liquid-solid ratio of described sodium hydroxide solution and the mushroom feet of Flammulina velutipes is 30:1mL / g, then in natural Carry out stack retting 5 days under the condition;

[0031] (2) After stacking and retting is completed, add gac to step (1) gain, and described gac is cell culture grade gac, and its serial number is: C118577, and the mass ratio of gac and Flammulina velutipes mushroom foot is 1:10; After fully mixing, add activated sludge to it, and use a batch anaerobic fermentation device for anaerobic fermentation to produce biogas; the mass ratio of activated sludge to Flammulina velutipes is 3:1, and the concentration of activated carbon is 20g / L. The total solid cont...

Embodiment 3

[0033] (1) Fermentation raw material selects the raw material among the embodiment 1.

[0034] (2) Anaerobic fermentation treatment:

[0035] (1) After adopting pulverizer to pulverize the feet of Flammulina velutipes, add the sodium hydroxide solution of mass concentration 1% wherein, the liquid-solid ratio of described sodium hydroxide solution and the mushroom feet of Flammulina velutipes is 20:1mL / g, then in nature Carry out stack retting 4 days under the condition;

[0036] (2) After stacking and retting is completed, add gac to step (1) gain, and described gac is cell culture grade gac, and its serial number is: C118577, and the mass ratio of gac and Flammulina velutipes mushroom foot is 1:8; After fully mixing, add activated sludge to it, and use a batch anaerobic fermentation device for anaerobic fermentation to produce biogas; the mass ratio of activated sludge to Flammulina velutipes is 3:1, and the concentration of activated carbon is 18g / L. The total solid conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com