Method for preparing methyl glycolate and by-producing methyl methoxyacetate

A technology for by-producing methyl methoxyacetate and methyl glycolate is applied to the preparation of carboxylic acid by the reaction of carbon monoxide, the preparation of carbon monoxide or formate, and the preparation of carboxylate, which can solve the problem of polluting the environment and affecting the catalytic reaction performance. , low conversion rate of raw materials, etc., to achieve the effect of increasing the ratio of CO and aldehyde groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

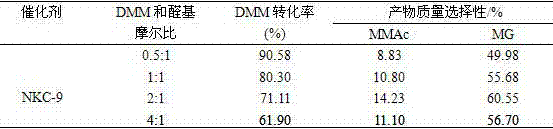

[0055] Weigh 20 kg of methylal (DMM), 300 g of NKC-9 catalyst, and 4 kg of water into the reactor. kg (the molar ratio of DMM to aldehyde group is 2:1), 7.8 kg (the molar ratio of DMM to aldehyde group is 1:1), 15.6 kg (the molar ratio of DMM to aldehyde group is 0.5:1), and then 1.0 MPa carbon monoxide gas is introduced, if After evacuating the gas in the kettle without leaking, repeat the above operation 2 times (replacing the air in the reactor). Introduce a certain amount of gas (6.0 MPa) again to test for leaks, and let it stand for 15 minutes. If the pressure indicator does not drop, it means that there is no air leakage in the device. Then empty the gas in the kettle and fill the kettle with 6.0 MPa CO gas again. , heated up, the stirring speed of the reactor was 500 rpm, the reaction pressure was 6.0MPa, the reaction temperature was 130°C, and the reaction time was 6 h. The effects of different ratios of DMM and aldehyde groups on the reaction are shown in Table 1.

...

Embodiment 2

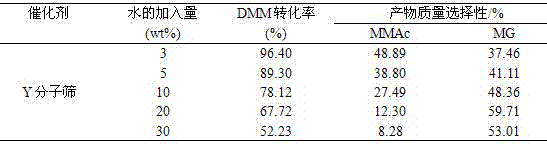

[0062] Weigh 20 kg of methylal (DMM), 3.9 kg of paraformaldehyde (the molar ratio of DMM to aldehyde group is 2:1), and 300 g of Y molecular sieve catalyst are loaded into the reaction kettle, and the amount of water added is the mass of methylal, respectively. 3%, 5%, 10%, 20%, 30%, and then pass in 1.0MPa carbon monoxide gas. If there is no leakage, after emptying the gas in the kettle, repeat the above operation twice (replace the air in the reactor). Introduce a certain amount of gas (6.0 MPa) again to test for leaks, and let it stand for 15 minutes. If the pressure indicator does not drop, it means that there is no air leakage in the device. Then empty the gas in the kettle and fill the kettle with 6.0 MPa CO gas again. , heated up, the stirring speed of the reactor was 500 rpm, the reaction pressure was 6.0 MPa, the reaction temperature was 130°C, and the reaction time was 6 h. The reaction results are shown in Table 2.

[0063] The impact of the addition of table 2 diff...

Embodiment 3

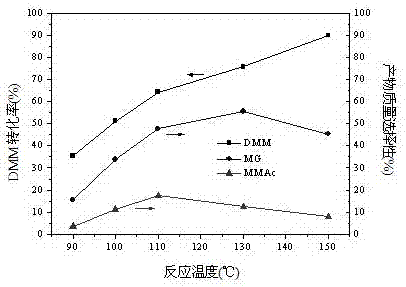

[0068] Weigh 20 kg of methylal (DMM), 3.9 kg of paraformaldehyde (the molar ratio of DMM to aldehyde group is 2:1), 4 kg of water, and 300 g of phosphotungstic acid catalyst are loaded into the reaction kettle, and then 1.0 MPa Carbon monoxide gas, if there is no leakage, after emptying the gas in the kettle, repeat the above operation twice (replace the air in the reactor). Introduce a certain amount of gas (6.0 MPa) again to test for leaks, and let it stand for 15 minutes. If the pressure indicator does not drop, it means that there is no air leakage in the device. Then empty the gas in the kettle and fill the kettle with 6.0MPa CO gas again. , heated up, the stirring speed of the reactor was 500 rpm, the reaction pressure was 6.0 MPa, the reaction temperatures were 90°C, 100°C, 110°C, 130°C, 150°C, and the reaction time was 6 h. The reaction results are shown in Table 3.

[0069] Table 3 Effects of different reaction temperatures on the conversion of raw materials and produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com