Preparing method of nano-silver-based composite bactericide

A compound bactericide and nano-silver technology, applied in the field of environmental chemistry, can solve the problems of unsatisfactory bactericidal effect, complicated preparation process, and inability to firmly combine, and achieve superior environmental friendliness, saving the amount of bactericide, and good physical and chemical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

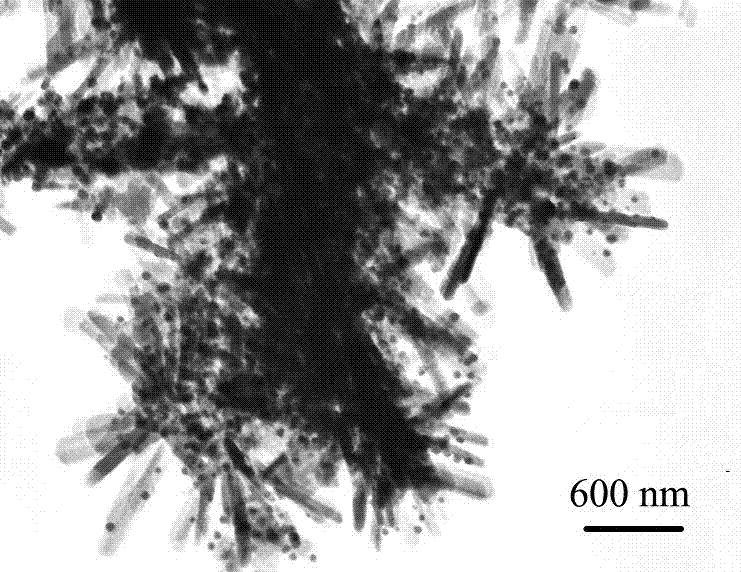

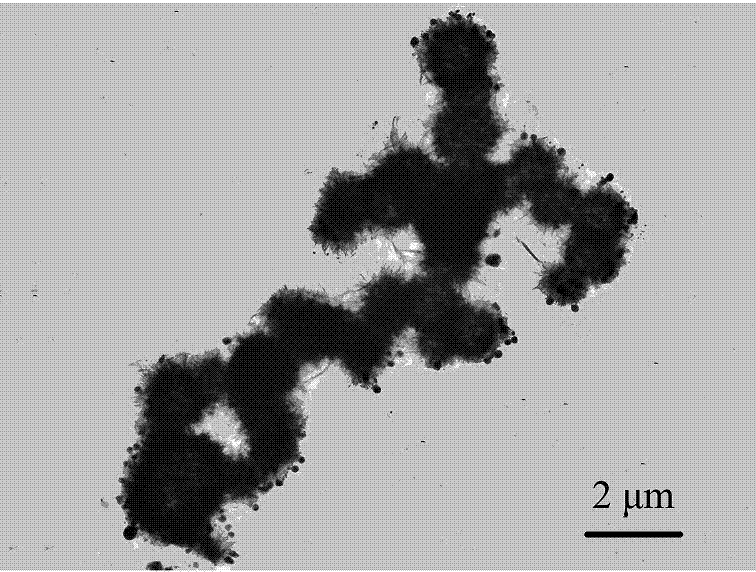

[0019] Measure 20 mL of 0.1 mol / L CaSO 4 Aqueous solution, 20 mL 0.06 mol / L NaH 2 PO 4 Add 0.02g of Triton X-100 to the aqueous solution, place the two solutions on both sides of the egg membrane, let it stand for 10 hours, until the system fully reacts, take the precipitates on both sides, wash and dry to obtain hydroxyapatite powder; 1 g of the obtained hydroxyapatite powder and 1 mL of complexed 0.15 mol / L AgNO 3 After mixing, add hydrazine hydrate and transfer to a hydrothermal kettle. After 24 hours of hydrothermal heating, filter and wash the precipitate to obtain a nano-silver-based composite fungicide.

Embodiment 2

[0021] Measure 20 mL of 0.1 mol / L CaSO 4 Aqueous solution, 20 mL 0.06 mol / L K 2 HPO 4 Add 0.02g of Triton X-100 to the aqueous solution, place the two solutions on both sides of the swim bladder, let it stand for 10 hours, until the system fully reacts, take the precipitates on both sides, wash and dry to obtain hydroxyapatite powder body; the obtained hydroxyapatite powder 1g and 2 mL complexed completely 0.15mol / L AgNO 3 After mixing, add hydrazine hydrate and transfer to a hydrothermal kettle. After 24 hours of hydrothermal heating, filter and wash the precipitate to obtain a nano-silver-based composite fungicide.

Embodiment 3

[0023] Measure 20 mL of 0.1 mol / L CaCl 2 Aqueous solution, 20 mL 0.06 mol / L NaH 2 PO 4 Add 0.02g of polyethylene glycol to the aqueous solution, place the two solutions on both sides of the egg membrane, let it stand for 10 hours, until the system fully reacts, take the precipitates on both sides, wash and dry to obtain hydroxyapatite powder ; The obtained hydroxyapatite powder 1g and 1 mL complexed completely 0.15mol / L AgNO 3 After mixing, glucose is added and then transferred to a hydrothermal kettle. After 24 hours of hydrothermal heating, the precipitate is suction-filtered and washed to obtain a nano-silver-based composite fungicide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com