Flame-retardant insulating vulcanized paper and preparation method thereof

A technology of steel paper and cellulose, applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., can solve the problem of unsatisfactory flame retardant effect of paper, poor dispersion of inorganic flame retardants, and low adsorption of flame retardant impregnating liquid, etc. problems, to achieve the effect suitable for large-scale production, high flame retardancy, high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

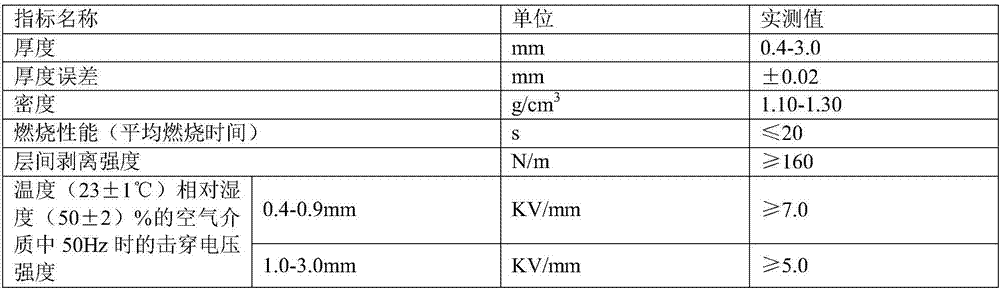

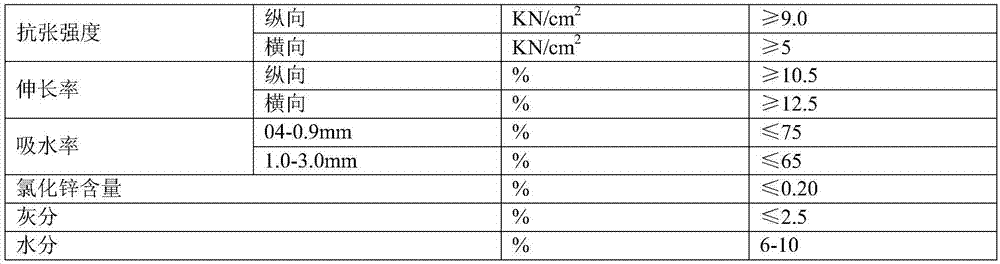

Examples

Embodiment 1

[0031] A fire-retardant insulating steel paper, which is made of 9 layers of base paper glued together. It is prepared from the following raw materials in parts by weight: 100 parts of wood pulp, 50 parts of cotton pulp, 4 parts of asbestos fiber, 400 parts of flame-retardant impregnated emulsion, 300 parts of swelling gelling solution, 12 parts of cellulose gas phase gel particles, fish 5 parts of bone meal, 1 part of ethylene glycol diglycidyl ether, 5 parts of fish maw extract gel.

[0032] Wherein, the solid content of the wood pulp and cotton pulp is 30wt%.

[0033] The flame retardant dipping emulsion consists of 6 wt% of dimethyl methyl phosphate, 0.75 wt% of emulsifier and the rest of water.

[0034] The swelling and gelling solution is a zinc chloride solution with a concentration of 15 wt%.

[0035] The preparation method of the cellulose air-phase gel particles is as follows: the wood powder is pressure-impregnated in a pressurized container containing 5 wt % pota...

Embodiment 2

[0044] A flame-retardant insulating steel paper, which is made of 12 layers of base paper gelled and bonded; it includes the following raw materials in parts by weight: 90 parts of wood pulp, 40 parts of cotton pulp, 3 parts of asbestos fiber, and 350 parts of flame-retardant impregnated emulsion , 200 parts of swelling and gelling liquid, 10 parts of cellulose gas-phase gel particles, 4 parts of fish bone meal, 0.5 parts of ethylene glycol diglycidyl ether, and 4 parts of fish maw extract gel.

[0045] Wherein, the solid content of the wood pulp and cotton pulp is 40wt%.

[0046] The flame retardant dipping emulsion consists of 4 wt% of dimethyl methyl phosphate, 0.5 wt% of emulsifier and the rest of water.

[0047] The swelling and gelling solution is a zinc chloride solution with a concentration of 20 wt%.

[0048] The preparation method of the cellulose air-phase gel particles is as follows: the wood powder is pressure-impregnated in a pressurized container containing 4wt...

Embodiment 3

[0057] A kind of flame-retardant insulating steel paper, which is made of 7 layers of base paper gelled and bonded; it includes the following raw materials in parts by weight: 110 parts of wood pulp, 60 parts of cotton pulp, 5 parts of asbestos fiber, and 450 parts of flame-retardant impregnated emulsion , 400 parts of swelling and gelling liquid, 14 parts of cellulose gas-phase gel particles, 6 parts of fish bone meal, 1.5 parts of ethylene glycol diglycidyl ether, and 6 parts of fish maw extract gel.

[0058] Wherein, the solid content of the wood pulp and cotton pulp is 20wt%.

[0059] The flame retardant dipping emulsion consists of 8 wt% of dimethyl methyl phosphate, 1 wt% of emulsifier and the rest of water.

[0060] The swelling and gelling solution is a zinc chloride solution with a concentration of 5wt%.

[0061] The preparation method of the cellulose air-phase gel particles is as follows:

[0062] Pressurize and impregnate the wood powder in a pressurized containe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com