Segmented crack self-healing repair method for laser remelting thermal barrier coating

A thermal barrier coating, laser remelting technology, applied in coating, metal material coating process, melt spraying and other directions, can solve the problems of high brittleness of ceramics, oxidation of bonding layer, interface cracking, etc., and reduce thermal radiation. , low loss rate, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0016] Laser laser remelting modified thermal barrier coating 3 on the workpiece. The material of the workpiece is a nickel-based superalloy, the model is Inconel718, and the size is 50mm×100mm×2mm. The surface of the workpiece is coated with a thermal barrier coating. The thermal barrier coating includes adhesive Junction layer 2 and ceramic layer 3, the thickness of the bonding layer 2 is about 0.1mm, the thickness of the ceramic layer 3 is about 0.3mm, the material of the bonding layer 2 is NiCoCrAlY, and the material of the ceramic layer 3 is 6%-8%Y 2 o 3 ZrO 2 .

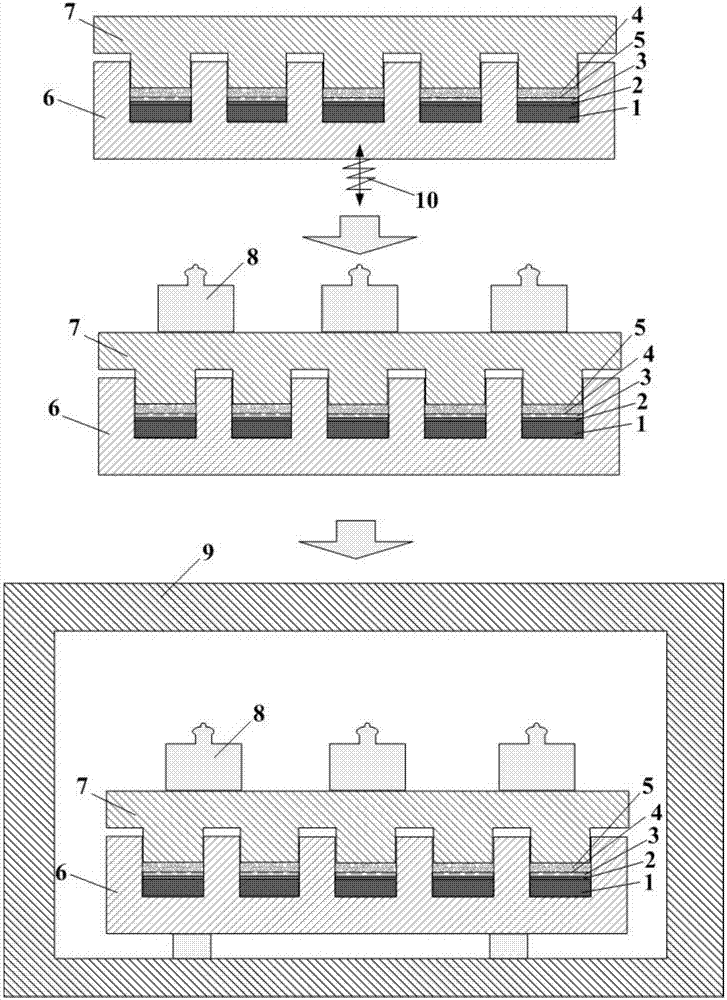

[0017] refer to figure 1 , a laser remelting thermal barrier coating segmentation crack self-healing repair method, comprising the following steps:

[0018] 1) Put the workpiece into the groove 6, the workpiece is the substrate 1 sprayed with the ceramic layer 3 and the bond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com