Sucrose crystallization device with dryer

A technology of crystallization device and dryer, which is applied in sugar crystallization, sugar drying, sucrose production, etc., and can solve the problems of large waste and high energy consumption of crystallization devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will now be further described in detail with reference to the accompanying drawings.

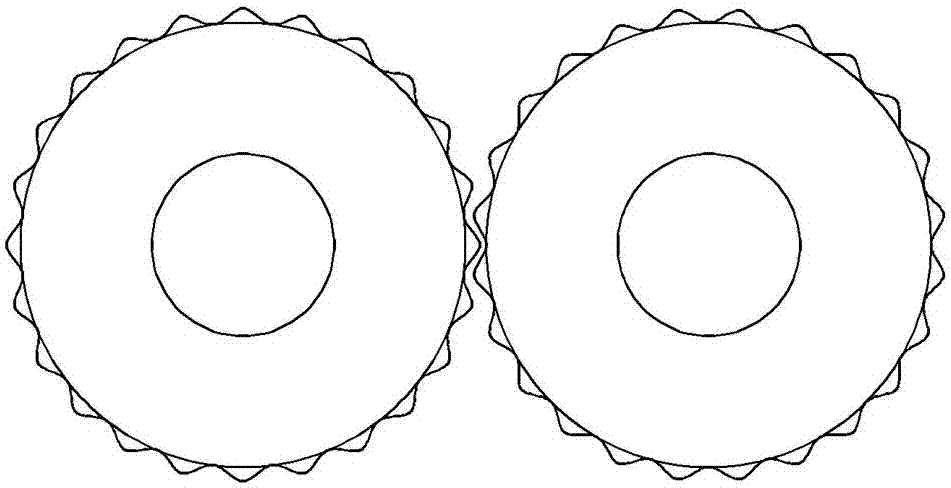

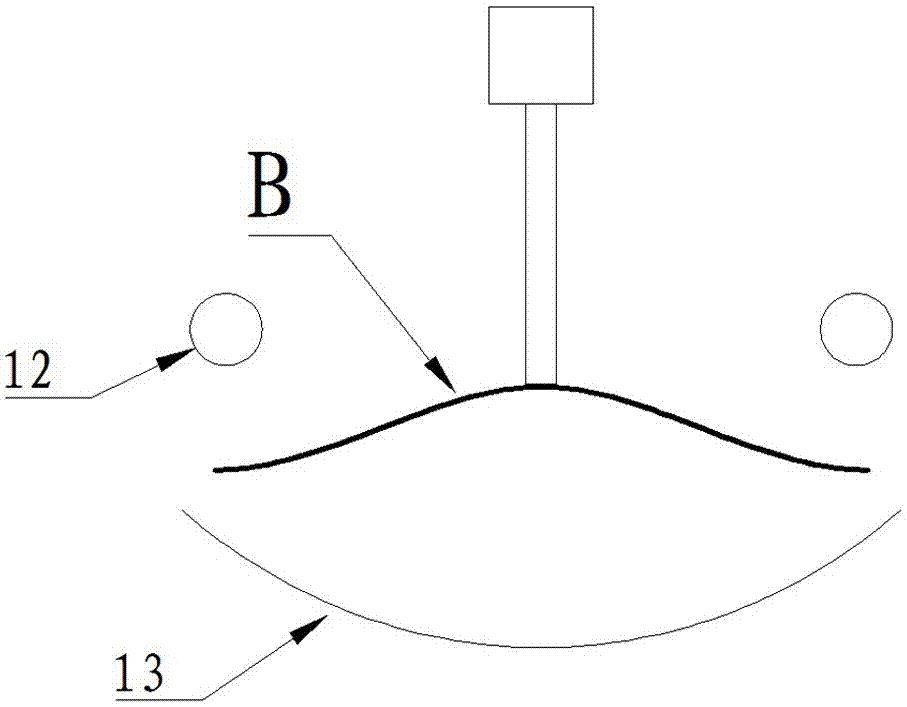

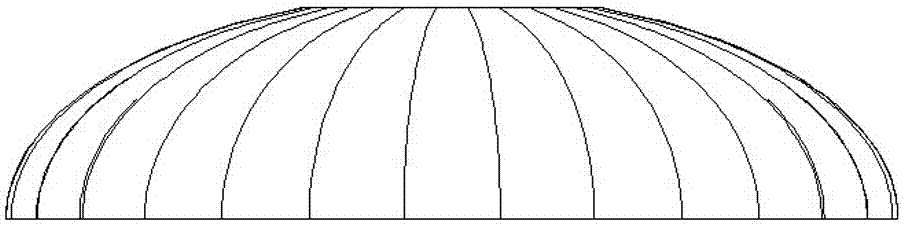

[0035] like Figure 1-Figure 8The shown sucrose crystallization device with dryer includes a crystallizer, and the crystallizer is connected to the bottom of the concentrator composed of the vapor-liquid separator 3 and the tube heat exchanger 5 through the dilute liquid pipe 8, and the tube heat exchanger 5 is located in the steam-liquid separator 3. There is a steam control valve 4 and a steam trap 7 under the liquid separator 3 for heating. The top of the vapor-liquid separator 3 is connected to the condensing vacuum system 1 through the vacuum pipe 2; Circulating pump 9, the outlet of the circulating pump 9 is connected to the plate heat exchanger 10 through a pipeline and then enters the lower inlet of the crystallizer; the inside of the crystallizer body 12 is a helical surface 11, and the outer circle of the helical surface is sealed with the crystallizer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com