Epoxy plasticizer synthesis method based on perrhenate ionic liquid

A technology of epoxy plasticizer and ionic liquid, which is applied in the fields of fatty acid oxidation, chemical instruments and methods, and fatty acid production. The effect of simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

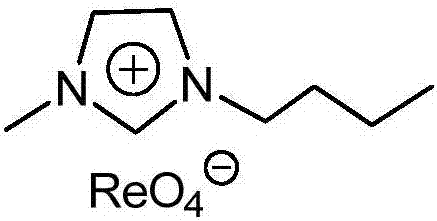

[0022] Example 1 1-butyl-3-methylimidazolium perrhenate ionic liquid ([Bmim]ReO 4 ) Catalyzed Synthesis of Epoxy Soybean Oil Plasticizer

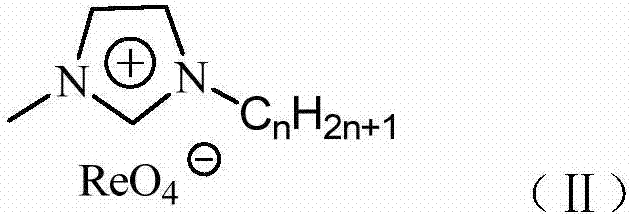

[0023] [Bmim]ReO 4 The structural formula is as follows:

[0024]

[0025] Weigh 0.5g[Bmim]ReO 4 Catalyst and 20g refined soybean oil are housed in the 50mL three-necked flask of reflux condenser, thermometer, under stirring, slowly drop 5g H 2 o 2 (30%), and slowly warming up to 60°C, stirring at 60°C for 6h. After the reaction is finished, after the reaction solution is cooled to room temperature, the catalyst is separated by centrifugation, the reaction solution is washed with water to neutrality, and dried to obtain a yellow oily product, which is an epoxidized soybean oil plasticizer.

[0026] According to GB / T 1677-2008, the epoxy value of the epoxidized soybean oil plasticizer is 6.35%, and according to GB / T 1668-2008, the acid value of the epoxidized soybean oil plasticizer is 0.45 mg KOH / g.

[0027] The separated catalyst ...

Embodiment 2

[0028] Example 2 1-butyl-3-methylimidazolium perrhenate ionic liquid ([Bmim]ReO 4 ) Catalyzed Synthesis of Epoxy Fatty Acid Methyl Ester Plasticizer

[0029] [Bmim]ReO 4 The structural formula is as follows:

[0030]

[0031] Weigh 0.5g[Bmim]ReO 4 Catalyst and 20g fatty acid methyl esters are housed in the 50mL three-necked flask of reflux condenser, thermometer, under stirring, slowly add dropwise 5g H 2 o 2 (30%), and slowly warming up to 60°C, stirring at 60°C for 6h. After the reaction is finished, after the reaction solution is cooled to room temperature, the catalyst is separated by centrifugation, the reaction solution is washed with water until neutral, and dried to obtain a yellow oily product, which is an epoxy fatty acid methyl ester plasticizer.

[0032] According to GB / T 1677-2008, the epoxy value of the epoxy fatty acid methyl ester plasticizer is 6.46%, and according to GB / T1668-2008, the acid value of the epoxy fatty acid methyl ester plasticizer is 0.4...

Embodiment 3

[0034] Example 3 1-hexyl-3-methylimidazolium perrhenate ionic liquid ([Hmim]ReO 4 ) Catalyzed Synthesis of Epoxy Soybean Oil Plasticizer

[0035] [Hmim] ReO 4 The structural formula is as follows:

[0036]

[0037] Weigh 0.5g[Hmim]ReO 4 Catalyst and 20g refined soybean oil are equipped with in the 50mL three-necked flask of reflux condenser, thermometer, under stirring condition, slowly drop 5g H 2 o 2 (30%), and slowly warming up to 60°C, stirring at 60°C for 6h. After the reaction is finished, after the reaction solution is cooled to room temperature, the catalyst is separated by centrifugation, the reaction solution is washed with water to neutrality, and dried to obtain a yellow oily product, which is an epoxidized soybean oil plasticizer.

[0038] According to GB / T 1677-2008, the epoxy value of the epoxidized soybean oil plasticizer is 6.25%, and according to GB / T 1668-2008, the acid value of the epoxidized soybean oil plasticizer is 0.44 mg KOH / g.

[0039] The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com