Novel self-leveling mortar and production technology thereof

A self-leveling mortar and production process technology, applied in the field of building materials, can solve the problems of high water absorption rate of gypsum, large environmental pollution, poor wear resistance, etc., and achieve the effects of low CO2 emission, wide application range and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

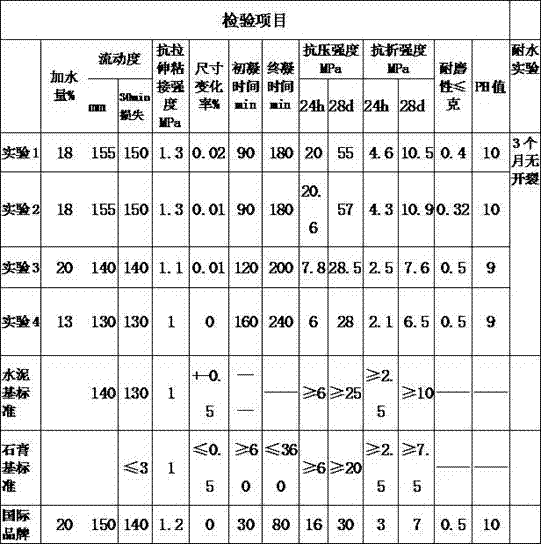

Examples

example 1

[0054] Example 1: Make a 6mm actual workshop floor of 100 square meters.

[0055] The ratio is: material A accounts for 70% of the total mass of the self-leveling mortar, and aggregate accounts for 30% of the total mass of the self-leveling mortar. Quartz sand and river sand with a mesh size of 0.05-0.2mm account for 20% of the total mass of the self-leveling sand slurry, and quartz sand and river sand with a mesh size of 0.1-0.3mm account for 10% of the total mass of the self-leveling sand slurry .

[0056] Material A is quantitatively and continuously delivered to the mixer with a spiral reamer, and the spare aggregate is quantitatively and continuously delivered to the mixer at the same time. Stir thoroughly for 4 minutes, and pack through the metering packaging device.

[0057] When using, the ratio of mortar to water is 18.5%, and it is fully stirred for 3 minutes. Its construction method is the same as cement-based and gypsum-based self-leveling.

[0058] On-site con...

example 2

[0061] Example 2: 200 square meters outside the actual workshop of 15mm.

[0062] The ratio is: material A accounts for 70% of the total mass of the self-leveling mortar, and aggregate accounts for 30% of the total mass of the self-leveling mortar. Quartz sand and river sand with a mesh size of 0.05-0.2mm account for 20% of the total mass of the self-leveling sand slurry, and quartz sand and river sand with a mesh size of 0.1-0.3mm account for 10% of the total mass of the self-leveling sand slurry .

[0063] Material A is quantitatively and continuously delivered to the mixer with a spiral reamer, and the spare aggregate is quantitatively and continuously delivered to the mixer at the same time. Stir thoroughly for 4 minutes, and pack through the metering packaging device.

[0064] When using, the ratio of mortar to water is 18.5%, and it is fully stirred for 3 minutes. Its construction method is the same as cement-based and gypsum-based self-leveling.

[0065] On-site con...

example 3

[0068] Example 3: Make a 5mm actual office floor of 30 square meters.

[0069] The ratio is: material A accounts for 50% of the total mass of the self-leveling mortar, and aggregate accounts for 50% of the total mass of the self-leveling mortar. The aggregates are river sand with a particle size of 0.05-0.2mm, which accounts for 40% of the total mass of the self-leveling sand slurry, and river sand with a particle size of 0.1-0.3mm accounts for 10% of the total mass of the self-leveling sand slurry.

[0070] Material A is quantitatively and continuously delivered to the mixer with a spiral reamer, and the spare aggregate is quantitatively and continuously delivered to the mixer at the same time. Stir thoroughly for 4 minutes, and pack through the metering packaging device.

[0071] When using, the ratio of mortar to water is 20%, and it is fully stirred for 3 minutes. Its construction method is the same as cement-based and gypsum-based self-leveling.

[0072] On-site constr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com