New carbon-based adsorption material and preparation method thereof

An adsorption material, carbon-based technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of high difficulty of vacuum desorption, slow adsorption and desorption rate, low molecular capacity, etc., and achieve excellent recycling performance. , the effect of lowering desorption temperature and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

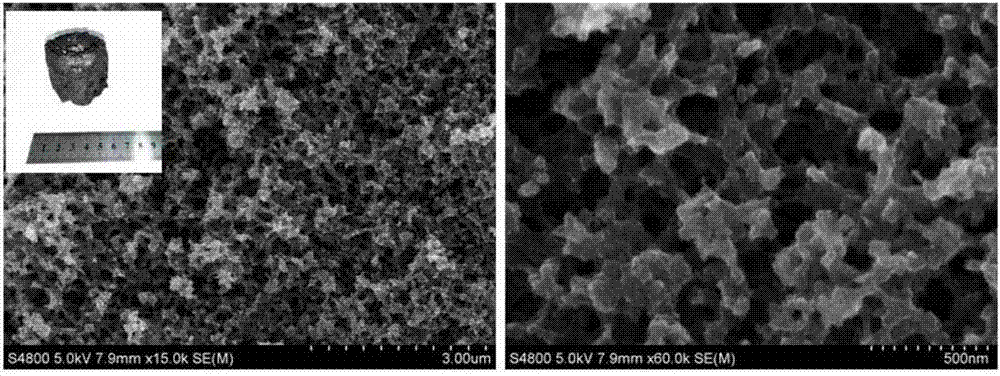

Embodiment 1

[0022] (1) First, dissolve 20 g of resorcinol in 40 ml of formaldehyde solution with a mass fraction of 37%, then add 0.9 g of glacial acetic acid dropwise, and stir for 10 minutes until the solution is completely uniform.

[0023] (2) Subsequently, the above mixed solution was stirred at a constant speed for 72 hours in a constant temperature environment of a water bath at 80° C. to obtain an orange-red gel block.

[0024] (3) Use liquid nitrogen to rapidly pre-freeze, put into a vacuum freeze dryer at -80°C and dry for 24 hours. After the dried sample is obtained, put it into the tubular heating furnace, exhaust the air in the tube and fill it with nitrogen protective gas, the gas velocity is 50 sccm, and then the temperature in the reaction furnace is raised to 750 °C at a heating rate of 5 °C / min for 3 hours. During the period, nitrogen gas was continuously fed;

[0025] (4) Then the temperature was raised to 900°C at 5°C / min and kept for 5 hours, during which carbon diox...

Embodiment 2

[0031] (1) First, dissolve 115g of resorcinol and 170g of formaldehyde in 300ml of deionized water, mix thoroughly, then add 4g of glacial acetic acid, and stir for 15 minutes to obtain a mixed solution.

[0032] (2) Subsequently, the above mixed solution was stirred at a constant speed for 24 hours in a constant temperature environment of a water bath at 80° C. to obtain an orange-red gel block.

[0033] (3) Use liquid nitrogen to rapidly pre-freeze, put into a vacuum freeze dryer at -80°C and dry for 24 hours. After the dried sample is obtained, put it into a tubular heating furnace, and under the protection of a nitrogen atmosphere with a gas velocity of 50 sccm, raise the temperature in the tubular furnace to 800 °C at a rate of 5 °C / min for 3 hours, and keep the nitrogen gas continuously flowing during the heating period ;

[0034] (4) Stop the nitrogen flow and replace it with carbon dioxide, keep the gas velocity constant, and at the same time raise the temperature to ...

Embodiment 3

[0042] (1) First, dissolve 12 g of resorcinol and 18 g of formaldehyde in 95 ml of deionized water, mix thoroughly, then add 0.45 g of glacial acetic acid, and stir for 20 minutes to obtain a mixed solution.

[0043](2) Subsequently, the above mixed solution was stirred at a constant speed for 48 hours in a constant temperature environment of a water bath at 90° C. to obtain an orange-red gel block.

[0044] (3) Use liquid nitrogen to rapidly pre-freeze, put into a vacuum freeze dryer at -85°C and dry for 36 hours. After the dried sample is obtained, put it into a tubular heating furnace, and under the protection of a nitrogen atmosphere with a gas velocity of 50 sccm, raise the temperature in the tube furnace to 600 °C at a rate of 7 °C / min for 6 hours, and keep the nitrogen gas continuously flowing during the heating period ;

[0045] (4) Stop the nitrogen flow and replace it with carbon dioxide, keep the gas velocity constant, and at the same time raise the temperature to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com