Polishing wheel feeding compensation mechanism of polishing machine

A technology of compensation mechanism and polishing wheel, which is applied to the parts of grinding machine tools, grinding/polishing equipment, grinding drive devices, etc., can solve problems such as uncontrollable, harsh environment, and slow speed, so as to improve production efficiency and ensure The effect of processing quality and strengthening stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

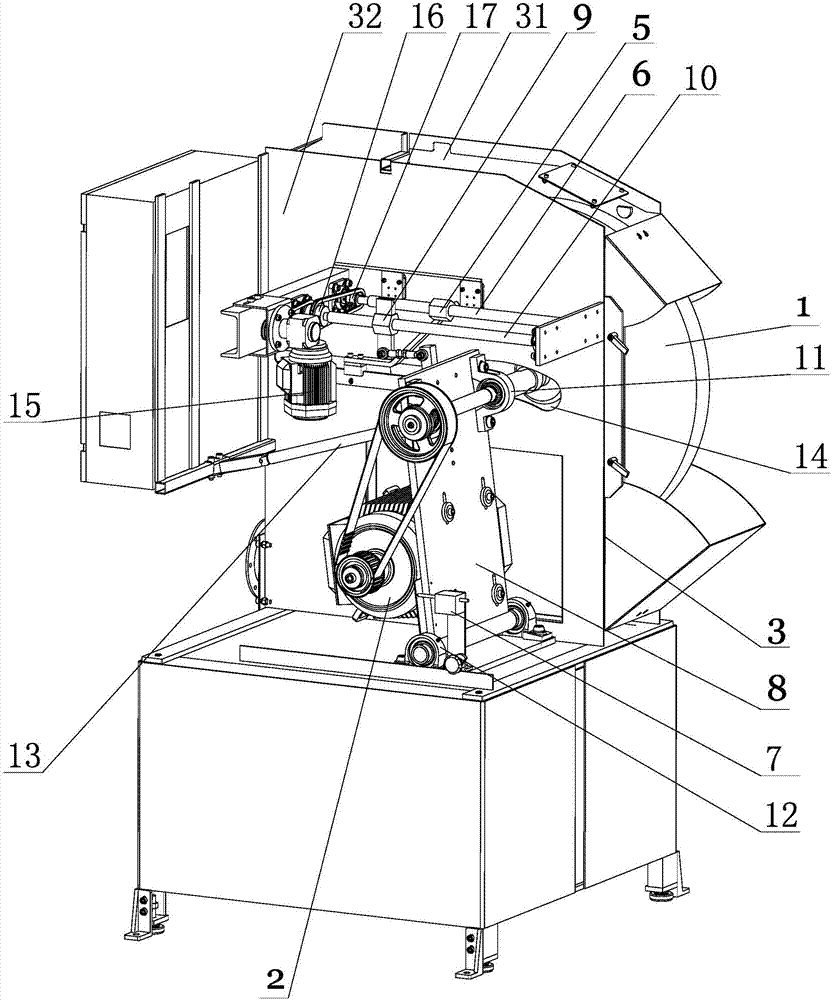

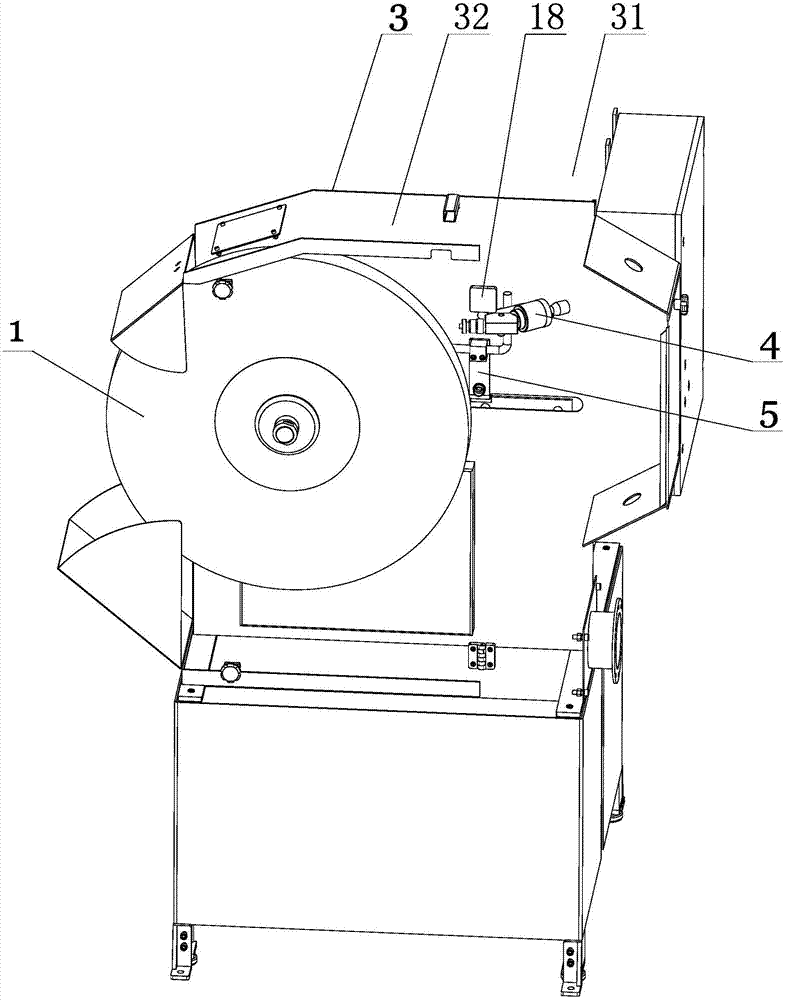

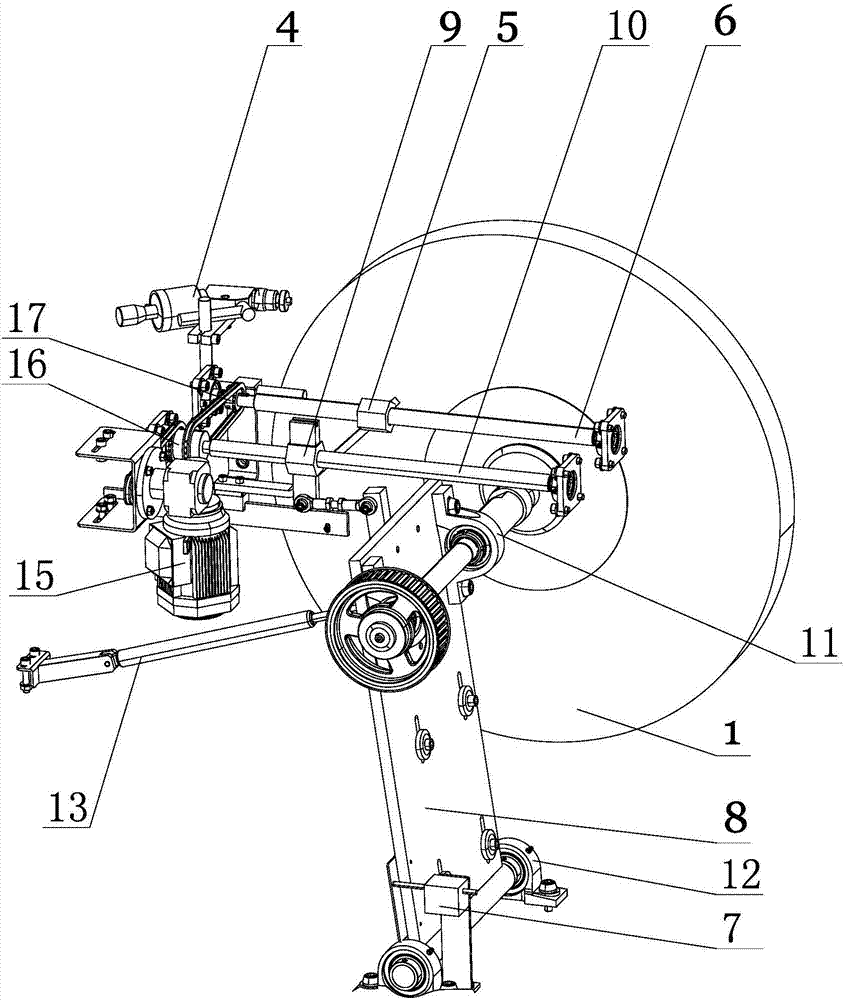

[0020] The present invention will be further described below in conjunction with accompanying drawing, according to Figure 1 to Figure 3 As shown, the polishing wheel feed compensation mechanism of the polishing machine of the present invention includes a polishing wheel 1 , a polishing drive motor 2 and a dust cover 3 . The dust cover 3 is provided with a processing chamber 31 for installing the polishing wheel 1 and a control chamber 32 for installing the polishing drive motor 2. The processing chamber 31 has a processing port for contacting with the workpiece, and the output shaft of the polishing drive motor 2 It is connected with the rotating shaft of the polishing wheel 1 through the output belt. Wherein, the control chamber 32 is provided with a compensation control component for driving the polishing wheel 1 to move forward or backward relative to the processing opening. The compensation control component includes a swing connection assembly and a compensation drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com