A ground oil sludge dry granulation equipment

A technology of landing oil sludge and dry granulation, which is applied in the direction of sludge treatment, chemical instruments and methods, raw material extrusion granulation, etc. It can solve the problems of increased water content, increased energy cost, and large consumption, and achieves the goal of reducing the expected cost. Dealing with energy consumption, reducing the amount of production, and high feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] According to the above technical scheme, this example provides a dry granulation process of the ground oil sludge, including sorting, crushing, granulation and modification. The role is to initially tear up the packaging bag that wraps the sludge. In the crushing stage, the large sludge is divided into smaller pieces, with an average size of 30cm. Part of the sludge is granulated into small particles. In the modification stage, the smaller sludge is divided into smaller pieces. Uniform sludge particles smaller than 1cm are thrown out obliquely, and the composite modifier is wrapped and modified during the throwing out process.

Embodiment 2

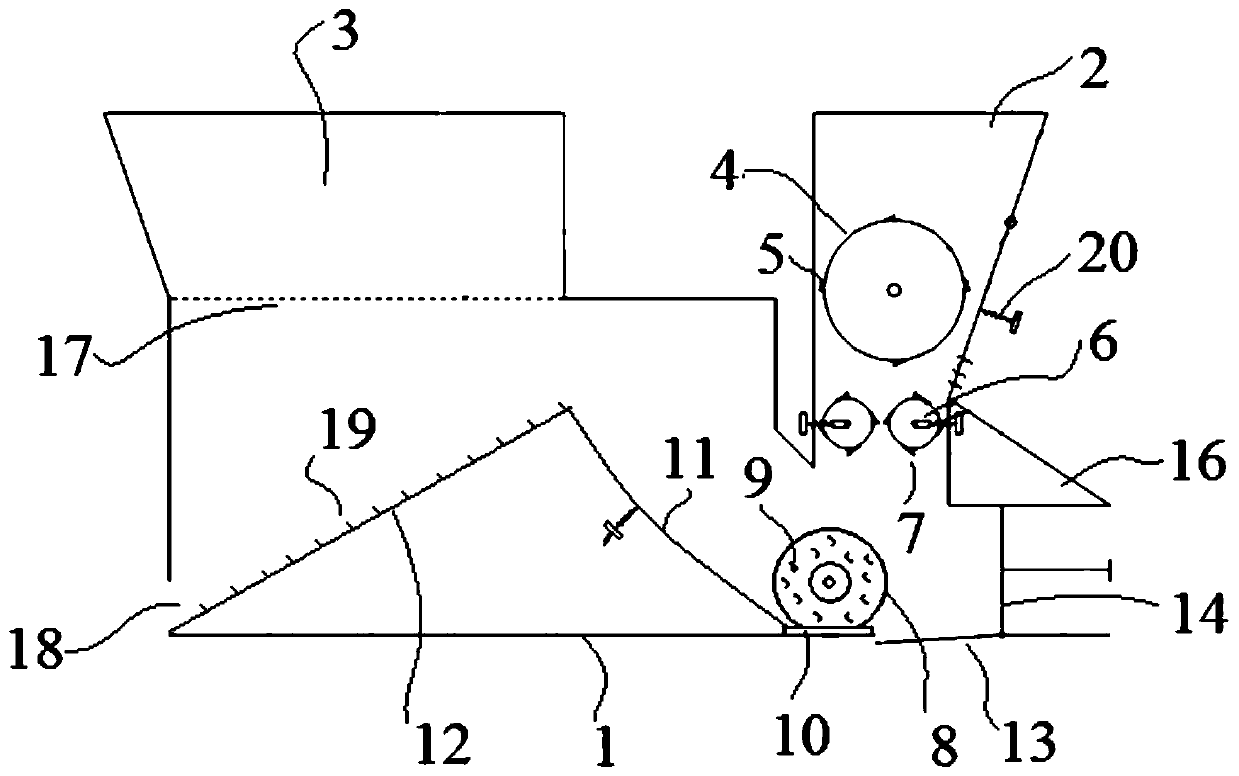

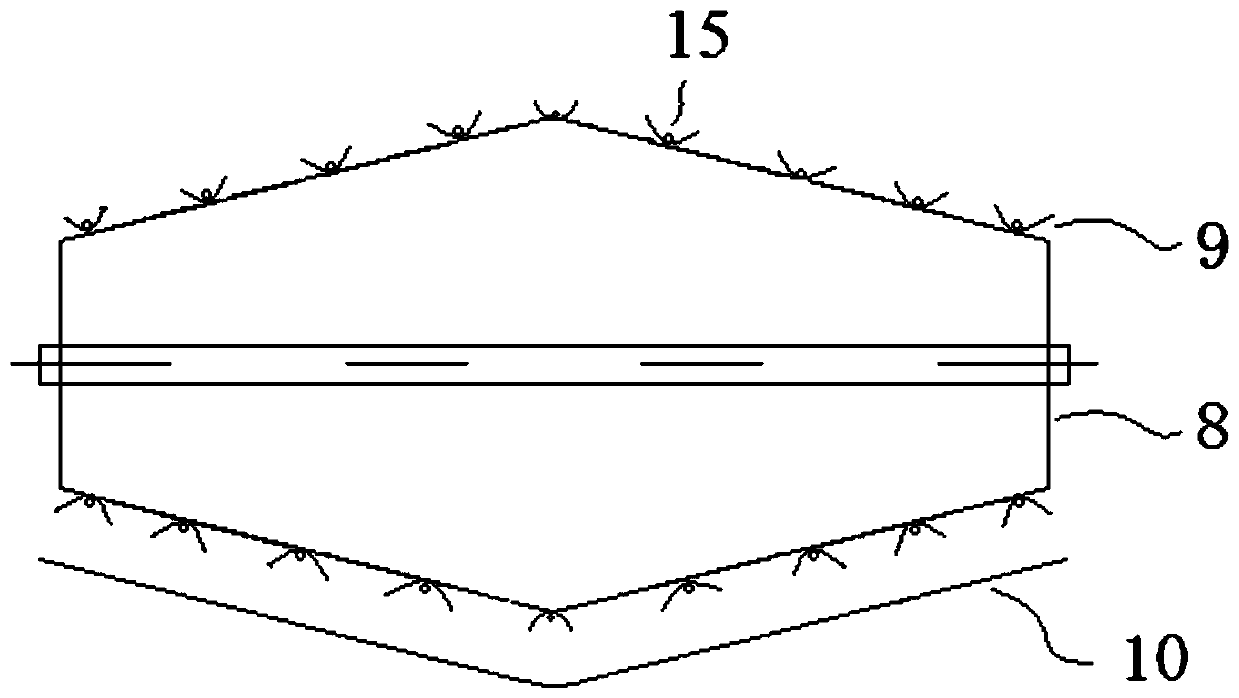

[0032] Comply with the above technical solutions, such as figure 1 , 2 As shown, this embodiment provides a dry granulation equipment for ground sludge, including a shell 1, the upper part of the shell 1 is respectively provided with a ground sludge inlet channel 2 and a composite modifier inlet channel 3, and the floor sludge inlet channel 2 A sorting shaft 4 is provided, and a plurality of sorting knives 5 are arranged on the sorting shaft 4, and a sorting bin 16 is arranged outside the housing near the side of the crushing shaft 6, and the housing 1 on the side of the sorting shaft 4 is connected to the sorting knives. The distance of the selection shaft 4 can be changed elastically (connected to the spring device). Foreign objects such as bricks and rubble are removed during the sorting stage. Moving, bricks, rubble, etc. can enter the sorting bin 16 for removal, and the crushing shaft 6 that rotates in opposite directions is arranged in the landing oil sludge inlet chann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com