A kind of method of hydrothermal-peracetic acid metal salt synergistic pretreatment of poplar fiber

A technology of metal peracetic acid and poplar fiber, which is applied in wood treatment, wood treatment details, fiber raw material treatment, etc. Improve the degradation and dissolution rate, low cost, and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The method for the synergistic pretreatment of poplar fiber by hydrothermal-peracetic acid metal salt of the present invention comprises the following steps:

[0032] S1, get the dry poplar chip raw material, pass through 40 mesh sieves after grinding and crushing, obtain poplar powder, and moisture content is 5.5%;

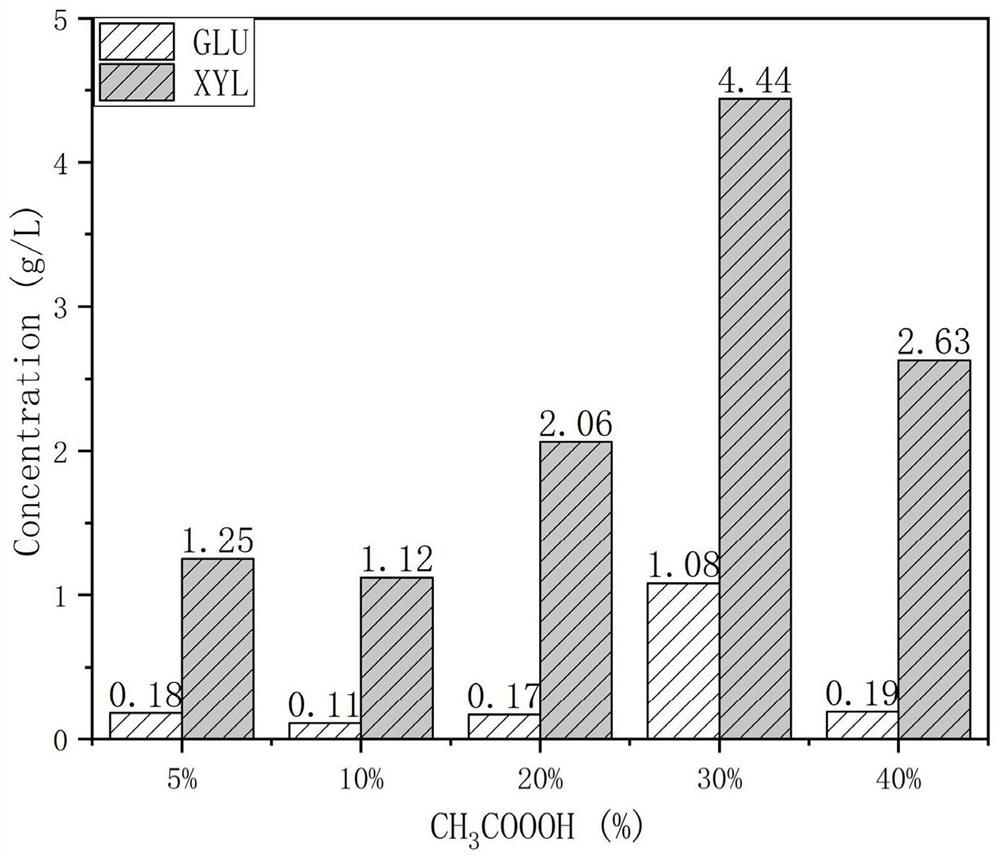

[0033] S2, take 1 g of poplar powder obtained in step S1, add 20 mL of peracetic acid solution with a volume solubility of 5v%, ultrasonically vibrate for 30 min, and let stand for 30 min to obtain a material mixture;

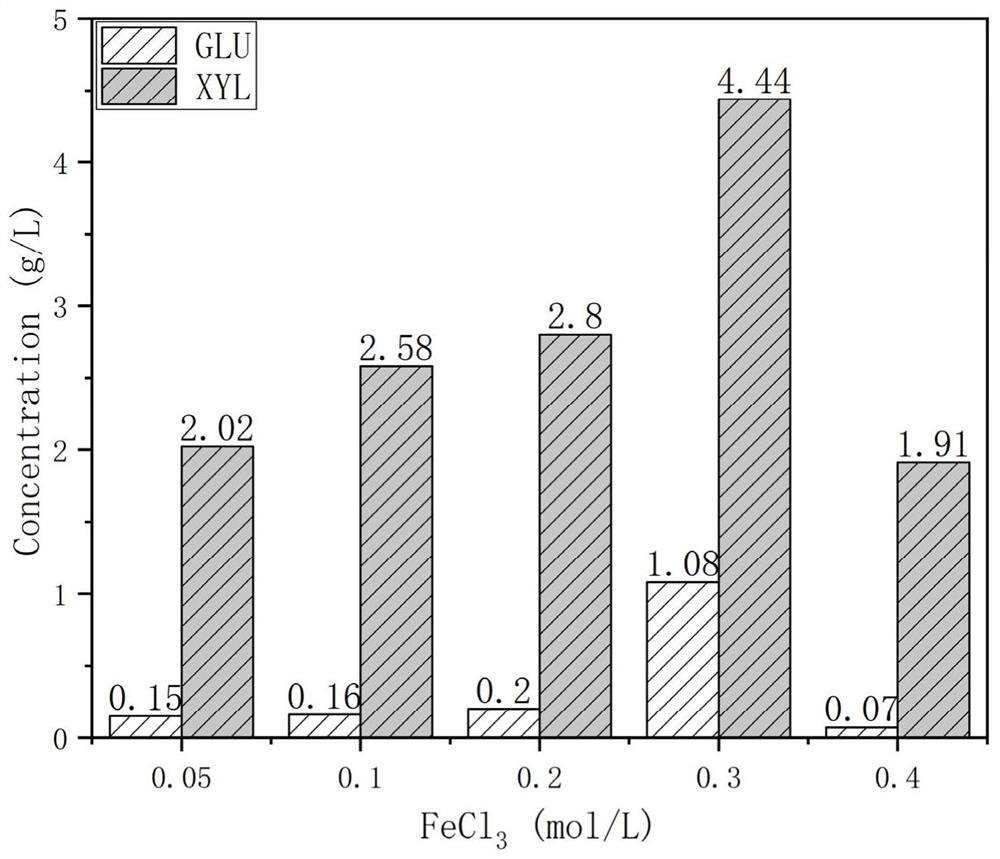

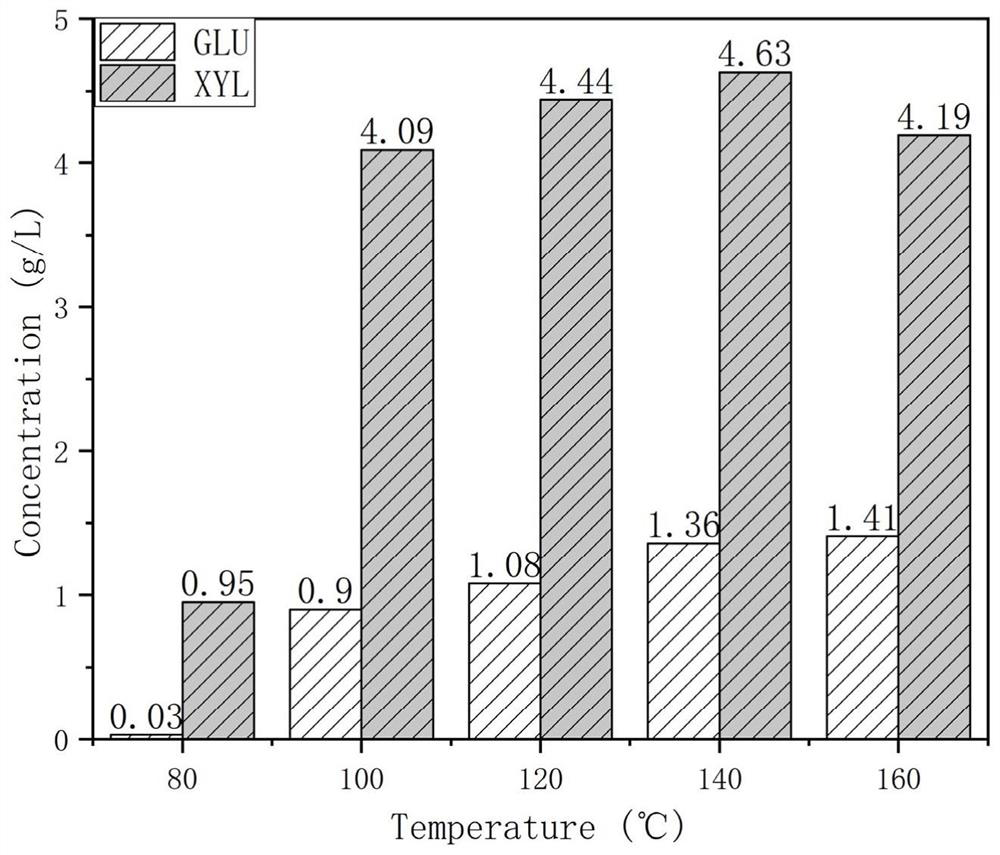

[0034] S3, in the material mixed solution obtained in step S2, add 1.08g of ferric chloride, and mix uniformly to obtain a mixture, that is, the concentration of ferric chloride in the mixture is 0.2mol / L, stand for 5min, and transfer to The three-necked flask was placed in an oil bath and heated to 120°C for hydrothermal reaction, and the reaction time was 20min;

[0035] S4. The reaction product obtained in step S3 is subjected to solid-...

Embodiment 2

[0039] The method for the synergistic pretreatment of poplar fiber by hydrothermal-peracetic acid metal salt of the present invention comprises the following steps:

[0040] S1, get the dry poplar chip raw material, pass through 40 mesh sieves after grinding and crushing, obtain poplar powder, and moisture content is 5.5%;

[0041] S2. Weigh 1 g of the poplar powder obtained in step S1, add 20 mL of peracetic acid solution with a volume solubility of 10 v%, ultrasonically vibrate for 30 min, and let stand for 30 min to obtain a material mixture;

[0042] S3, in the material mixed solution obtained in step S2, add 1.08g ferric chloride, and after mixing evenly, obtain a mixture, that is, the concentration of ferric chloride in the mixture is 0.2mol / L, stand for 5min, transfer to The three-necked flask was placed in an oil bath and heated to 120°C for hydrothermal reaction, and the reaction time was 20min;

[0043] S4. The reaction product obtained in step S3 is subjected to so...

Embodiment 3

[0045] The method for the synergistic pretreatment of poplar fiber by hydrothermal-peracetic acid metal salt of the present invention comprises the following steps:

[0046] S1, get the dry poplar chip raw material, pass through 40 mesh sieves after grinding and crushing, obtain poplar powder, and moisture content is 5.5%;

[0047] S2. Weigh 1 g of the poplar powder obtained in step S1, add 20 mL of peracetic acid solution with a volume solubility of 20 v%, ultrasonically vibrate for 30 min, and let stand for 30 min to obtain a material mixture;

[0048] S3, in the material mixed solution obtained in step S2, add 1.08g ferric chloride, and after mixing evenly, obtain a mixture, that is, the concentration of ferric chloride in the mixture is 0.2mol / L, stand for 5min, transfer to The three-necked flask was placed in an oil bath and heated to 120°C for hydrothermal reaction, and the reaction time was 20min;

[0049] S4. The reaction product obtained in step S3 is subjected to so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com