Treatment device for solid product of pyrolysis rotary kiln

A processing device and rotary kiln technology, which is applied in the field of pyrolysis rotary kiln solid product processing devices, can solve the problems of incomplete gasification of bulk reactants, long gasification process and high volatile content, and reduce energy consumption for pretreatment. , The effect of improving the yield of finished products and reducing residual volatiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

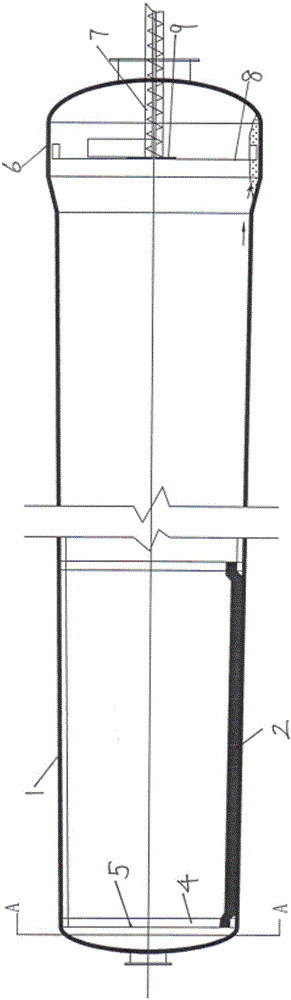

[0013] A pyrolysis rotary kiln solid product treatment device, comprising a solid product pulverization device arranged at the front of the rotary kiln body 1, and a collection and discharge mechanism arranged at the rear of the rotary kiln body;

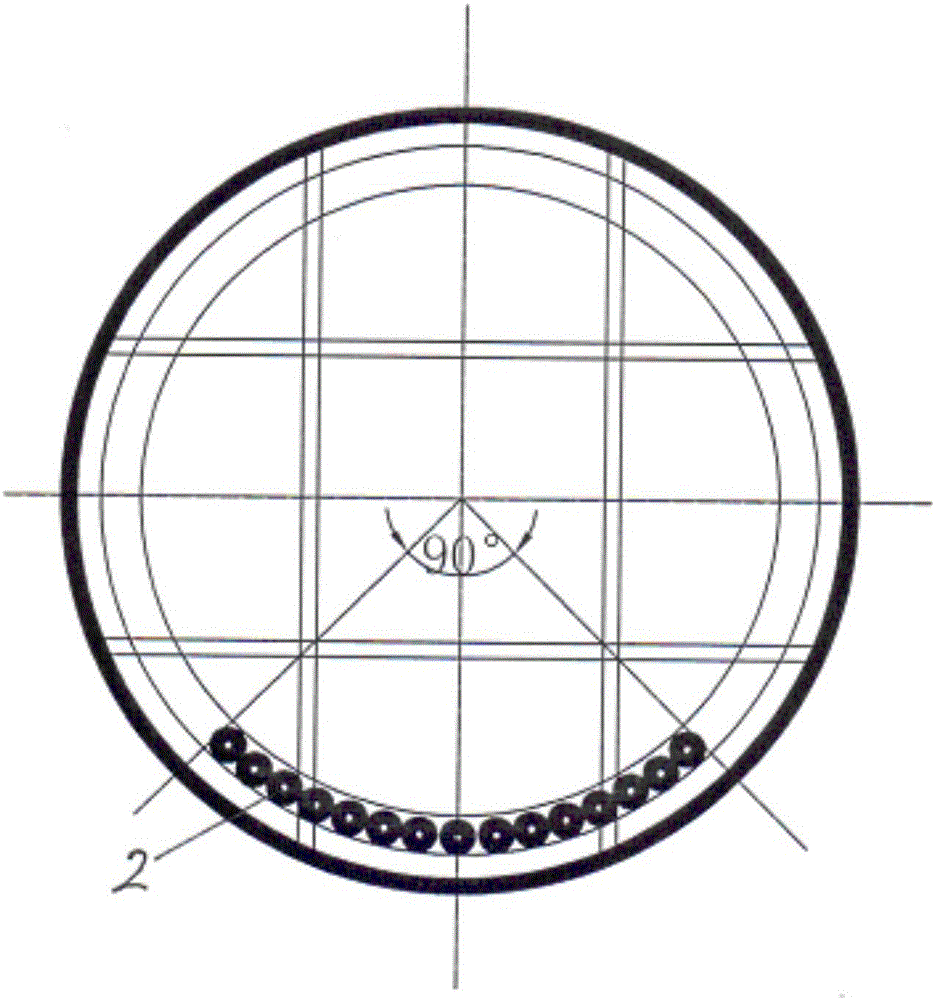

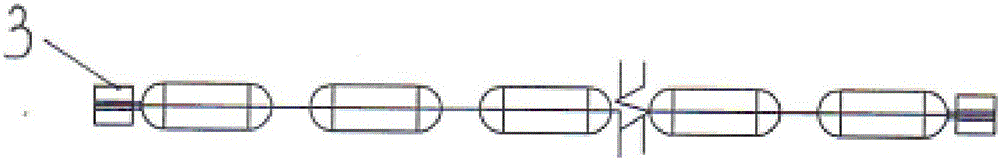

[0014] The solid product powdering device includes a plurality of chains 2 closely arranged in the axial direction to form an arc surface, which is in direct contact with the kiln wall. On the circular track 4, when the rotary kiln is rotating or shutting down, under the action of gravity, the arc-shaped surface formed by the chain is always located at the bottom of the rotary kiln and covers the bottom kiln wall, forming the second dynamic kiln wall;

[0015] The collection and discharge mechanism includes an enlarged diameter section 6 located at the end of the rotary kiln body. The kiln wall of the enlarged diameter section forms a collection tank; The long-arm digging spoon 8 that lifts the solid waste in the collection tank and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com