Fully closed floor heating heat-insulation type concrete plant

A concrete, fully enclosed technology, applied in mixing plants, clay preparation devices, mixing operation control, etc., can solve the problem that the silo can not meet the construction requirements of strong wind and heavy snowfall in the north, and cannot guarantee the concrete discharge, mold entry temperature, etc. Concrete can not be constructed and other problems, to achieve the effect of being conducive to civilized construction, good lighting effect, and good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

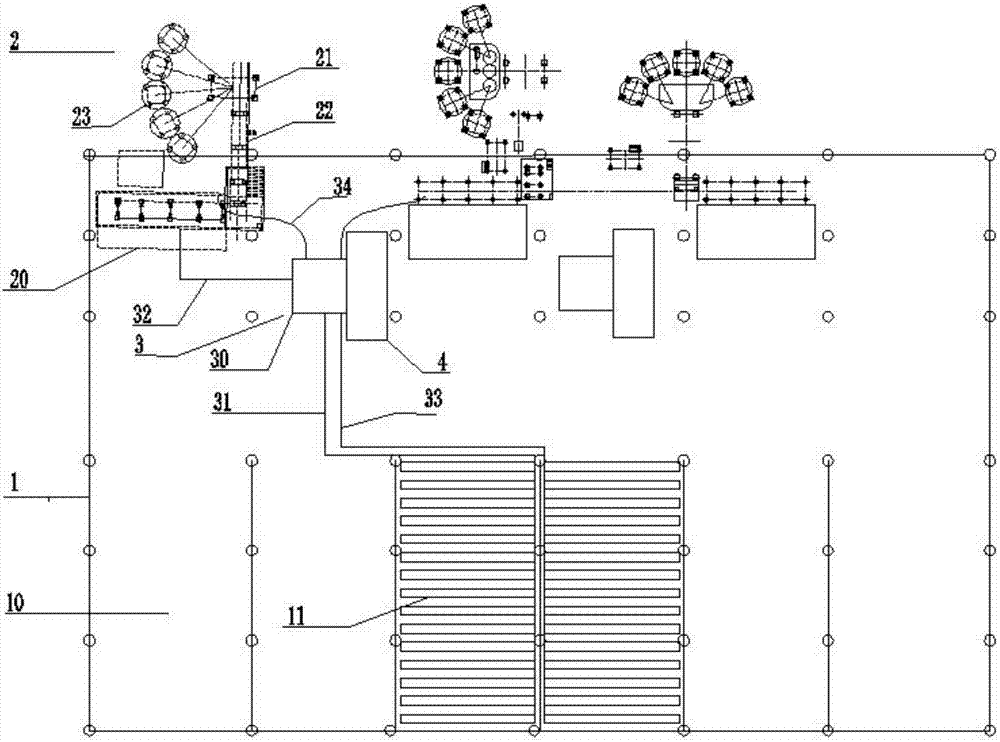

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0029] see figure 1 As shown, the embodiment of the present invention provides a fully enclosed floor heating and heat preservation concrete factory, which includes:

[0030] A closed silo shed 1. Several sand and gravel silos 10 are arranged in the silo shed 1. At least one of the sand and gravel silos 10 has a ground heating groove at the bottom of the silo. When the sand and gravel needs to be used, the silo can be The sand and gravel in the silo without the floor heating groove at the bottom is transferred to the sand and gravel silo 10 with the floor heating groove at the bottom of the silo, which can save construction costs, and the heating pipeline is laid in the floor heating groove 11. The floor heating trench is covered with a steel cover plate to seal it, so as to heat and keep the sand and gravel;

[0031] Mixing station 2, it co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com