Method for machining thin-wall bearing rings by adopting digital controlled lathe

A technology of thin-walled bearings and CNC lathes, which is applied to bearing components, shafts and bearings, metal processing equipment, etc., and can solve problems such as difficult to ensure ring size accuracy, shape accuracy, position accuracy, surface roughness, and deformation of bearing rings , to achieve the effect of ensuring the consistency of precision, reducing stress deformation and meeting process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

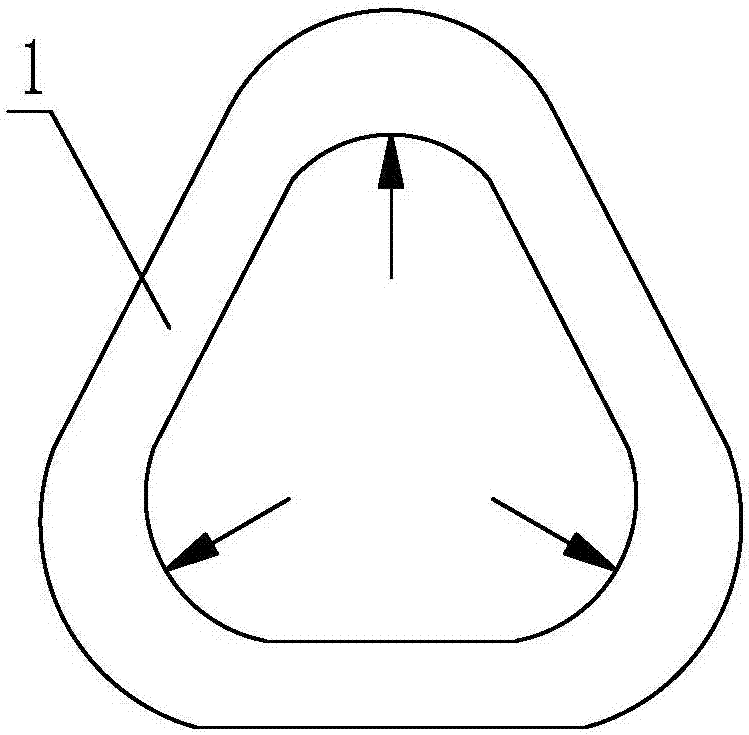

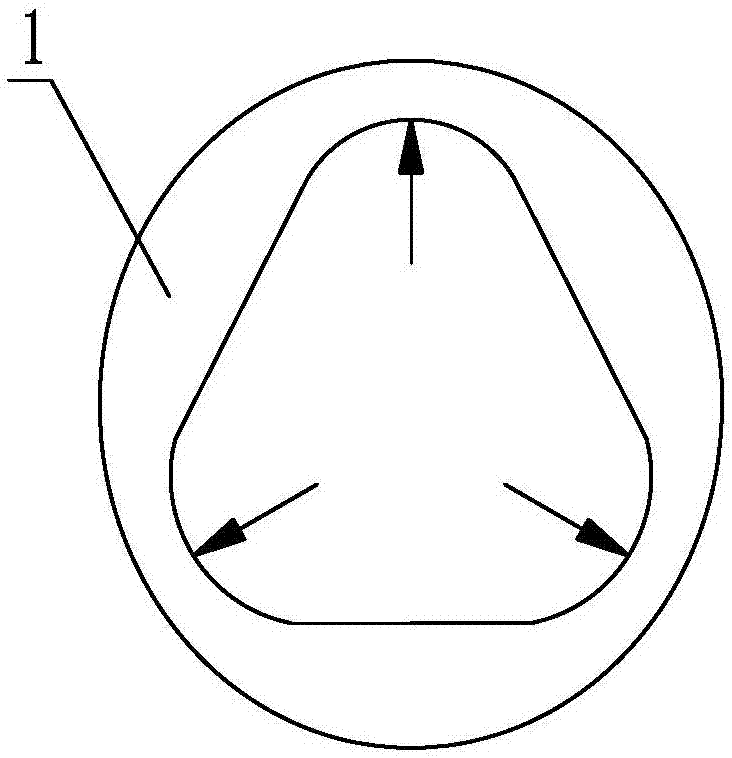

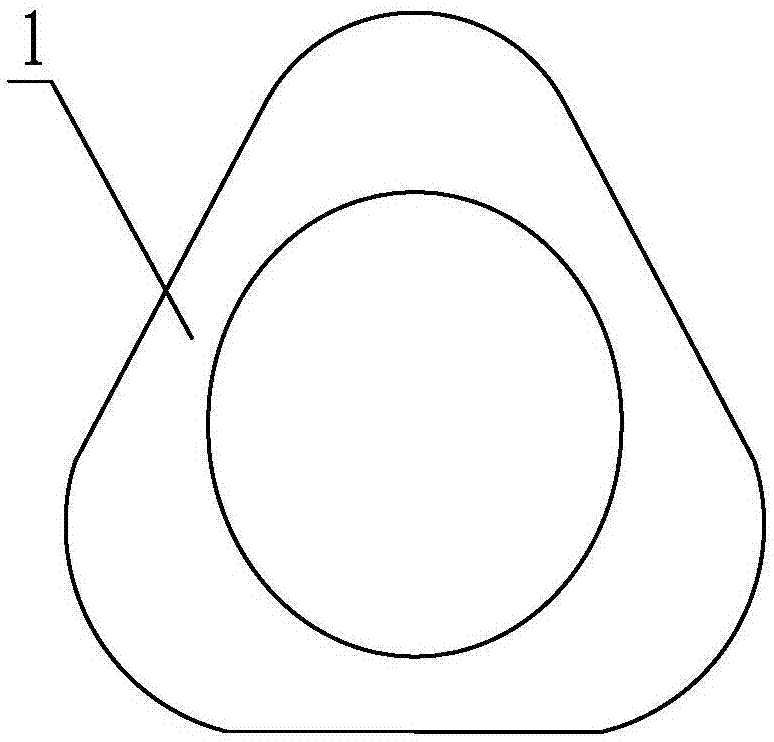

[0030] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment, a thin-walled bearing ring CNC lathe processing method of this embodiment, the method includes the following steps:

[0031] Step 1. Clamping of thin-walled bearing ring 1:

[0032] When the thin-walled bearing ring 1 is processed by CNC lathe, the first jaw 2 of the CNC lathe is used to clamp the thin-walled bearing ring 1, and the included angle of the first jaw 2 is α, α=110°-130 °;

[0033] Step 2, rough turning the outer diameter and inner diameter of the thin-walled bearing ring 1:

[0034] The thin-walled bearing ring 1 is rough turned by the first numerically controlled blade, and the linear speed of the first numerically controlled blade is v 1 , v 1 =160m / min-180m / min, the feed rate is f 1 , f 1 =0.22mm / r; the sharp corner radius of the first CNC blade is R 1 , R 1 =1.5mm-1.2mm, turning allowance is Z 1 ,Z 1 =0.6mm-0.8mm,

[0035] Step 3, finish turning the out...

specific Embodiment approach 2

[0039] Specific implementation mode two: combination Figure 5 To describe this embodiment, the included angle α of the first clamping jaw 2 in Step 1 of this embodiment is 120°. With such arrangement, the first clamping jaw 2 with an included angle of 120° makes the clamping state of the bearing ring 1 just not slipping, and the clamping force is the smallest, and the clamping effect is the best. The contact area between the first jaw 2 and the ring 1 is increased to ensure that under the same clamping force, the deformation range of the ring 1 is effectively reduced, and the dimensional accuracy and accuracy of the bearing ring 1 are improved. shape precision. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0040] Specific implementation mode three: combination Figure 1 to Figure 3 Describe this embodiment, the linear velocity v of the first numerically controlled blade in the step 2 of this embodiment 1 =170m / min, the sharp corner radius R of the first CNC blade 1 = 1.3mm, turning allowance Z 1 = 0.7 mm. Such setting effectively reduces the deformation range of the ferrule 1, ensures the surface roughness and accuracy requirements of the rough-turned thin-walled bearing ferrule 1, and improves the positional accuracy and dimensional accuracy of the rough-turned bearing ferrule. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com