Application of polysiloxane used as coating on kitchen utensil

A technology for polysilazane and cooking utensils, applied in the directions of application, coating, device for coating liquid on the surface, etc., can solve the problems of no polysilazane coating, no polysilazane non-stick material, etc. , to achieve the effect of aesthetic safety, excellent adhesion and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

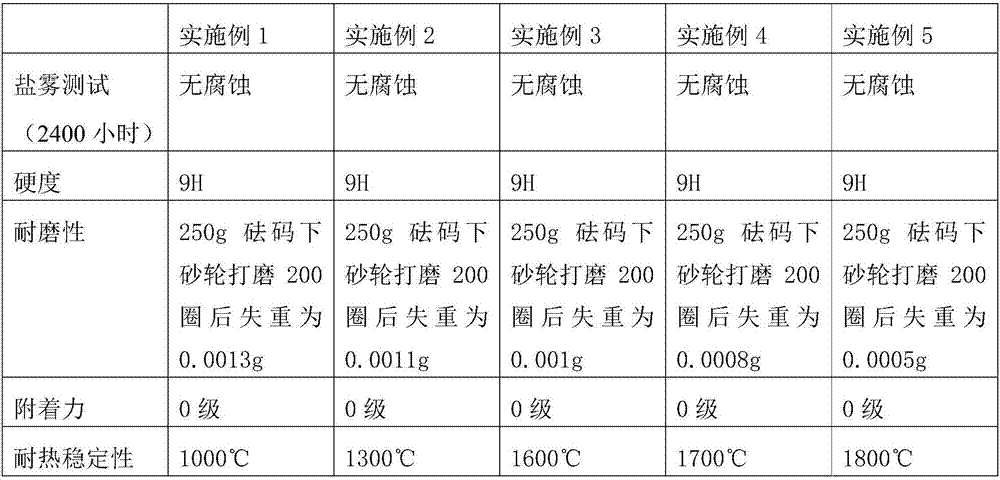

Embodiment 1

[0045] In this embodiment, polysilazane is applied to a stainless steel pot.

[0046] Polysilazane is applied on the stainless steel pan body as a non-stick pan coating, and the method for applying polysilazane to the pan body comprises the following steps:

[0047] 1) Polishing: polishing the inner surface of the stainless steel pot to make the inner surface smooth;

[0048] 2) Cleaning: Clean the stainless steel pot body with pure water or deionized water, and then dry it;

[0049] 2) coating: polysilazane is sprayed on the inner surface of the cleaned stainless steel pot body, and the thickness of the sprayed coating is 20um;

[0050] 3) Curing: the sprayed stainless steel pot body was placed in a high-temperature furnace at 100° C. for sintering for 2 hours, thereby forming a non-stick coating on the inner surface of the stainless steel pot body.

Embodiment 2

[0052] In this embodiment, polysilazane is applied to an aluminum alloy pot body.

[0053] Polysilazane is applied on the aluminum alloy pan body as a non-stick pan coating, and the method for applying polysilazane to the pan body comprises the following steps:

[0054] 1) Polishing: Polish the inner surface of the aluminum alloy pot to make the inner surface smooth and flat;

[0055] 2) Cleaning: Clean the aluminum alloy pot body with pure water or deionized water, and then dry it;

[0056] 3) Coating: wipe polysilazane on the inner surface of the cleaned aluminum alloy pot, and the coating thickness is 25um;

[0057] 4) Curing: the aluminum alloy pan body after wiping polysilazane was placed at room temperature 25° C., and cured for 48 hours, thereby forming a non-stick coating on the inner surface of the aluminum alloy pan body.

Embodiment 3

[0059] In this embodiment, polysilazane is applied to a cast iron pot.

[0060] Polysilazane is applied on the cast iron pan body as a non-stick pan coating, and the method for applying the polysilazane to the pan body comprises the following steps:

[0061] 1) Polishing: Polish the inner surface of the cast iron pot to make the inner surface smooth;

[0062] 2) Cleaning: Clean the cast iron pot with pure water or deionized water, and then dry it;

[0063] 3) Coating: Vibration-coat polysilazane on the surface of the cleaned cast iron pot with a coating thickness of 30um;

[0064] 4) Curing: put the cast iron pan body coated with polysilazane in a high-temperature furnace at 180° C. for sintering for 40 minutes, so as to form a non-stick coating on the surface of the cast iron pan body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com