Picking, feeding, smashing and slicing integrated branch processing machine

A technology for processing machines and branches, applied in grain processing, agricultural machinery and implements, cutting tools, etc., can solve the problems of requiring many people, time-consuming and laborious, etc., achieving a high degree of automation, ensuring the feeding amount, and the distribution of axial spring teeth. tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

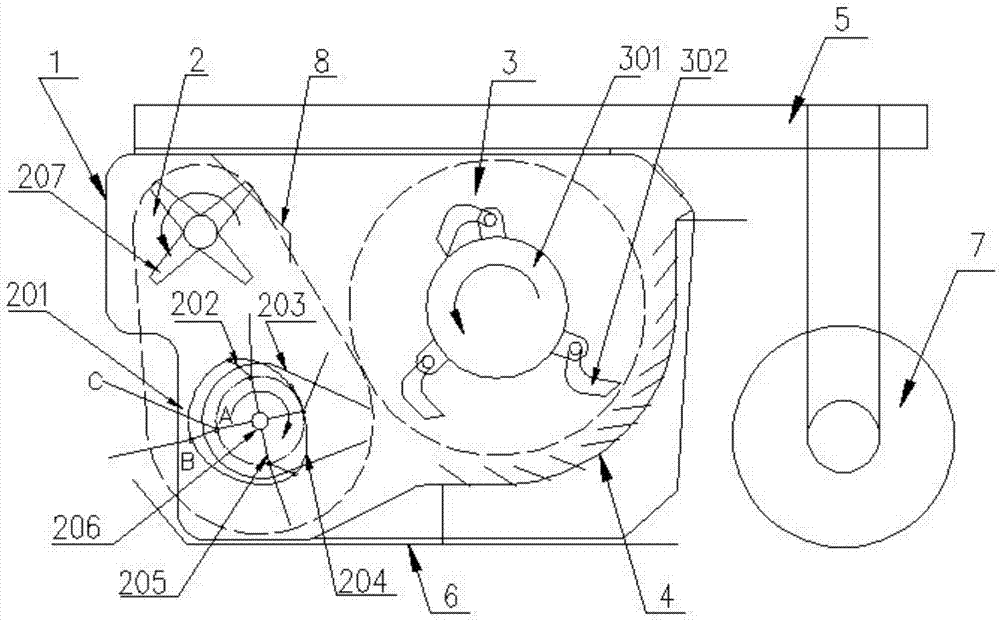

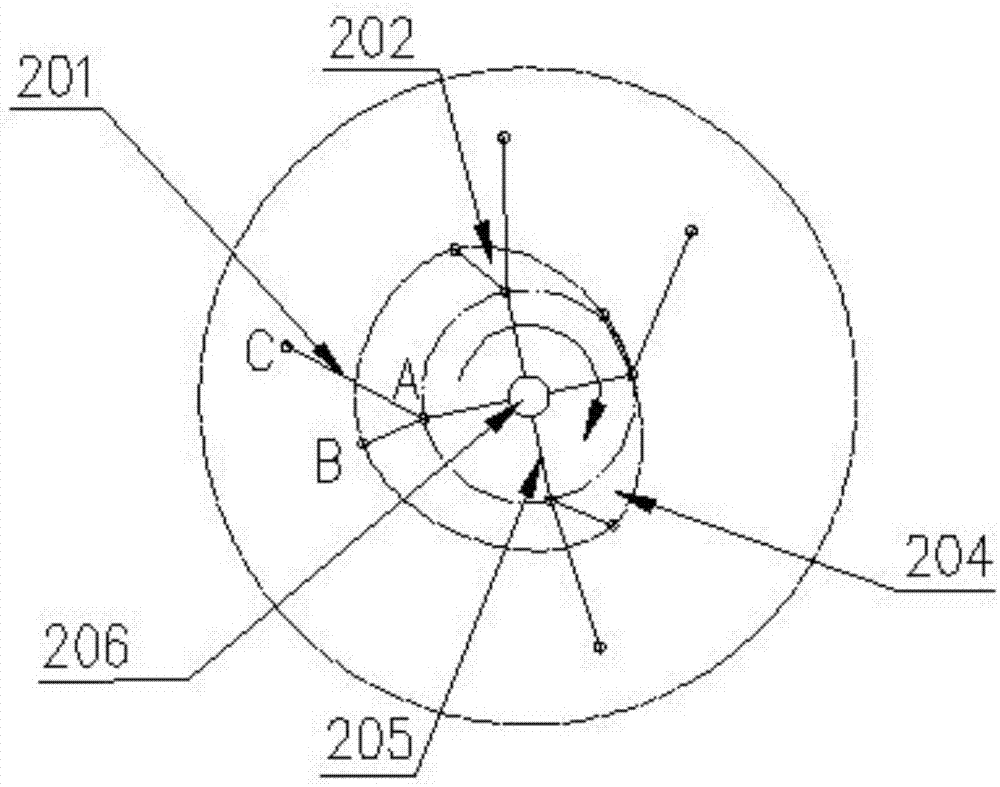

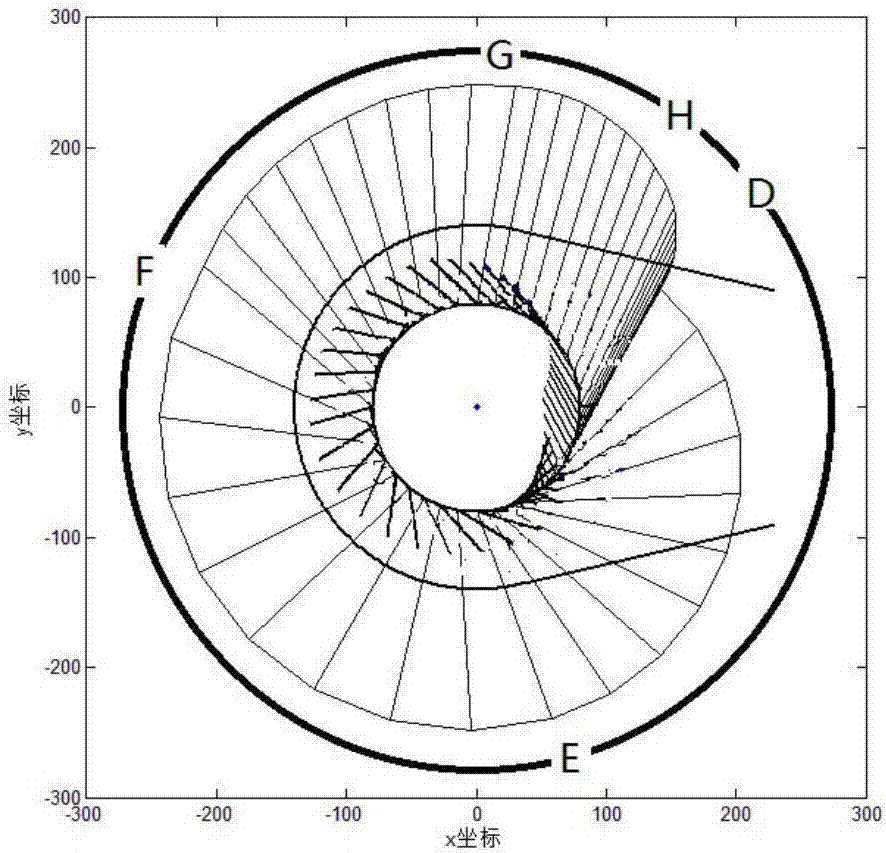

[0024] Such as Figure 1-5 As shown, a branch processing machine integrating picking, feeding, crushing and slicing includes a frame 1, and the inside of the frame 1 is equipped with a picking and feeding mechanism 2, a crushing mechanism 3, a discharge mechanism 4 and Transmission suspension mechanism 5, the bottom of described frame 1 is provided with slide plate 6, and frame 1 is installed on the tractor that power is used by described transmission suspension mechanism 5, and the bottom of described transmission suspension mechanism 5 is provided with supporting follower wheel 7 , the bottom of the frame 1 is provided with a slide plate 6 that is convenient for moving forward; during work, the picking and feeding mechanism 2 picks up branches from the ground, and feeds them into the cavity of the subsequent crushing mechanism 3 after being raised. After completing the crushing operation, the crushed branches are evenly thrown out to both sides behind the frame 1 by the disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com