Control valves for controlling media, especially fuels

A technology for controlling valves and media, which is applied to fuel injection devices, valve devices, valve details, etc., and can solve problems such as expensive structures, large structural space and complexity of pressure regulating systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

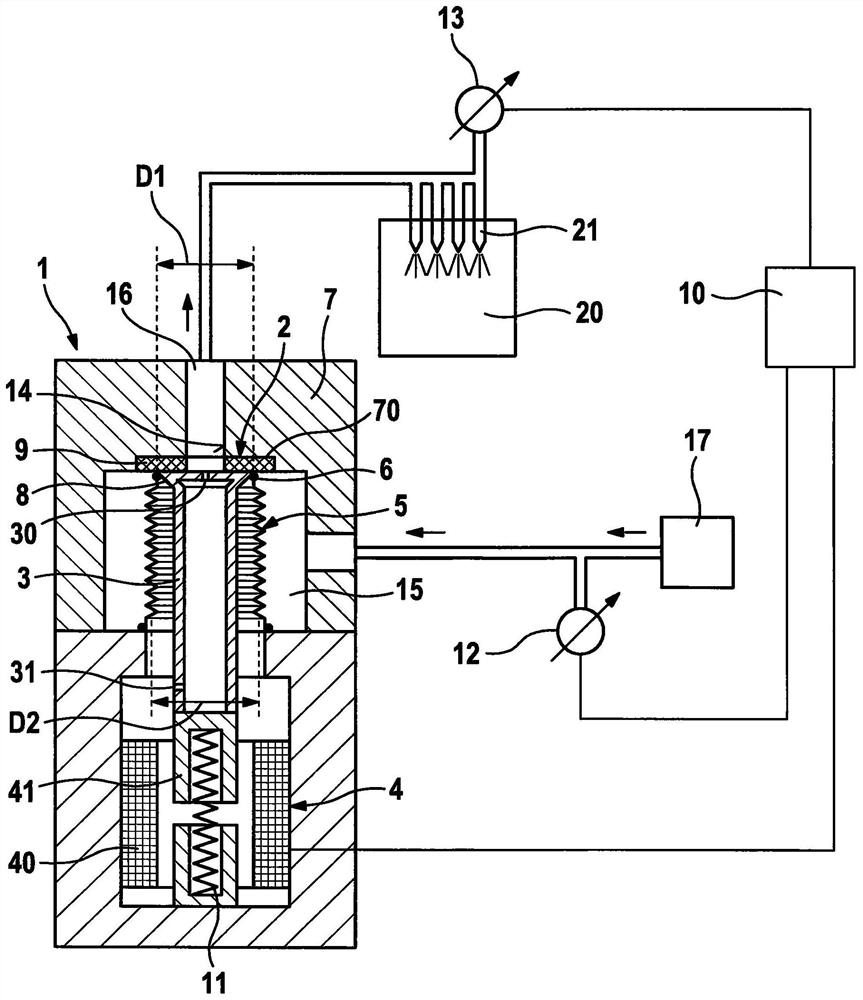

[0018] Refer below figure 1 The control valve 1 for controlling the medium will be described in detail.

[0019] The control valve 1 comprises a sealing seat 2 and a valve element 3 , which in this exemplary embodiment is a valve piston. The valve element 3 has a widened region 8 at the end facing the sealing seat 2 . The widened region 8 widens conically. The valve piston is hollow and has two compensating openings 30 , 31 .

[0020] Furthermore, the control valve 1 comprises an actuator 4 , which in this embodiment is an electromagnetic actuator. The actuator 4 comprises a coil 40 and an armature 41 which is connected to the valve element 3 .

[0021] Furthermore, the valve element 3 is arranged in the bellows 5 . The bellows 5 is fastened to the widened area 8 of the valve element 3 by means of a welded connection. More precisely, the valve element 3 has an outermost maximum diameter D1 on the sealing seat 2 and the bellows 5 has an average diameter D2. Here, the ave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com