Flexibly-packaged ternary power battery and preparation method thereof, and positive pole piece of battery

A battery positive electrode and positive electrode sheet technology, which is applied to battery electrodes, small-sized batteries/battery packs, large-sized batteries/battery packs, etc., can solve problems such as poor safety performance, fire and explosion of battery cells, and improve battery life. Performance, prevention of explosion, effects of stress buffering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

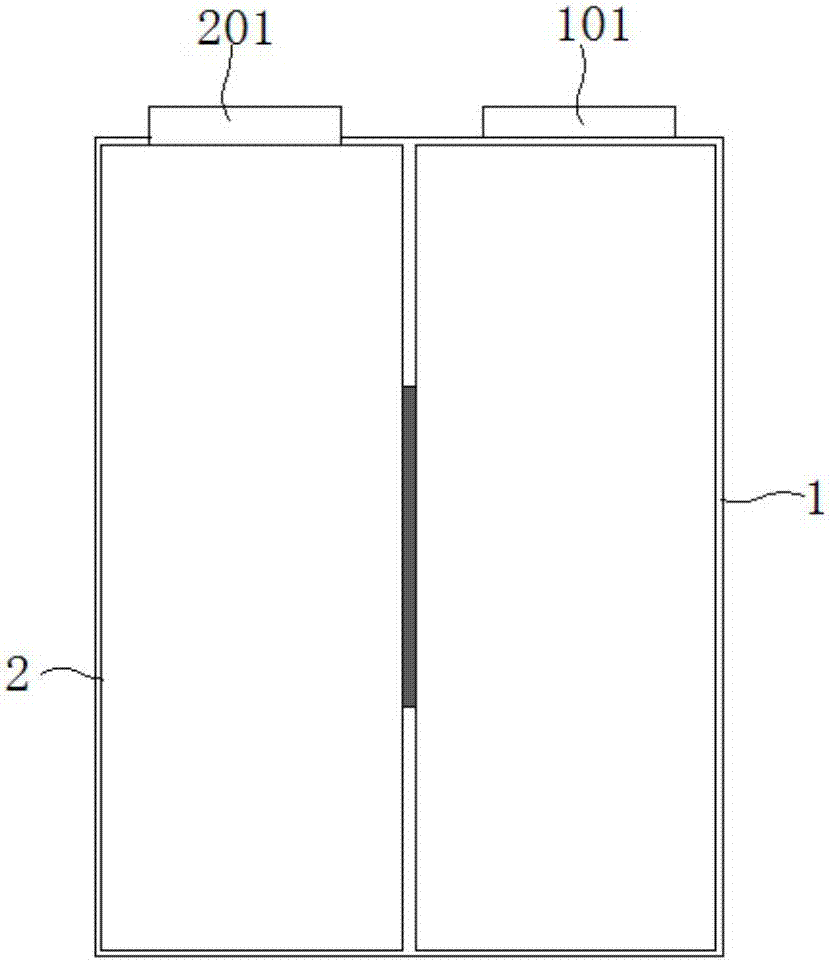

[0055] Such as figure 1 As shown, a soft pack ternary power battery (3.65V / 40Ah) of this embodiment includes a positive pole piece 2, a negative pole piece 1, a diaphragm, an electrolyte and a battery case, wherein the positive pole piece 2, the negative pole piece The pole piece 1 and the diaphragm form a diaphragm / negative electrode / diaphragm / positive electrode laminated battery core. The diaphragm is coated with polyethylene+ceramics, the thickness of the diaphragm is 15 μm, the electrolyte is lithium hexafluorophosphate, and the battery case is packaged by aluminum-plastic film.

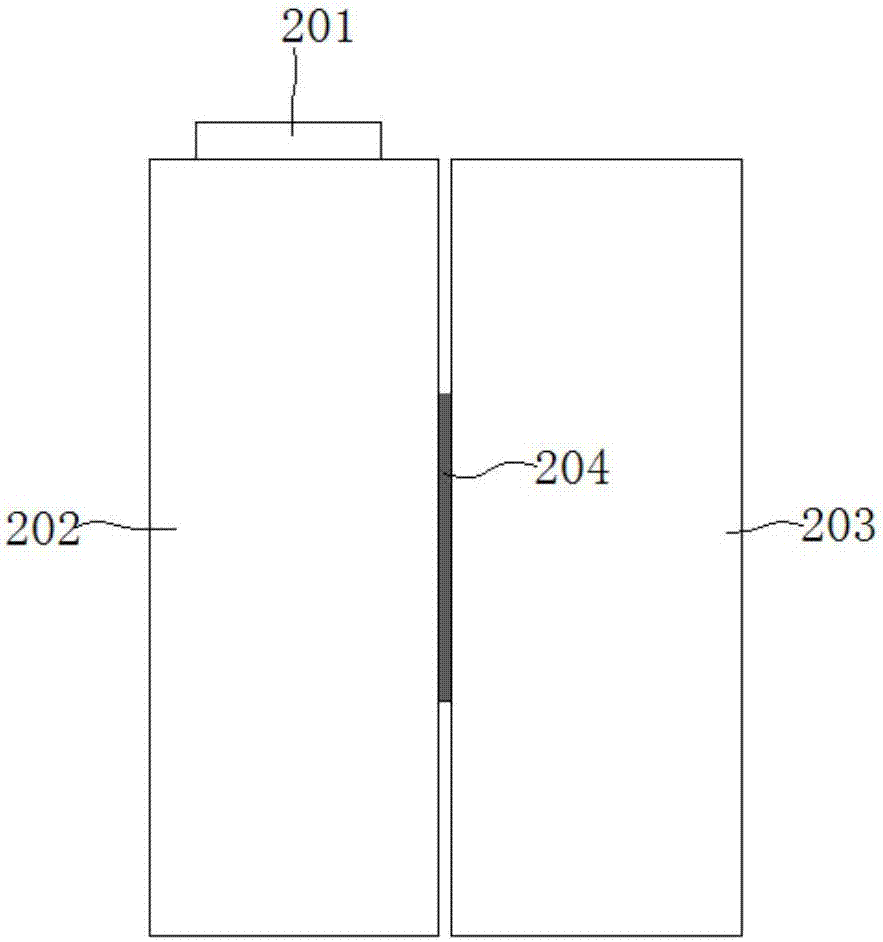

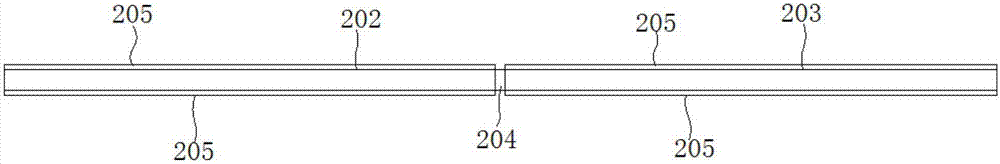

[0056] Such as figure 2 , image 3 As shown, the positive electrode sheet 2 includes a positive electrode current collector, and the positive electrode current collector adopts an aluminum foil with a thickness of 12 μm. The positive electrode current collector includes a first coating area 202, a second coating area 203 and a connection area 204. The first A coating area 202 is connected to ...

Embodiment 2

[0081] A soft pack ternary power battery (3.65V / 30Ah) of this embodiment has the same structure as that of Embodiment 1, the difference being that the positive current collector is made of aluminum foil with a thickness of 16 μm, and the thickness of the diaphragm is 15 μm. The length of the connection area 204 is 1 / 8 of the length of the first coating area 202 and the second coating area 203 , and the width is 1 / 65 of the width of the first coating area 202 and the second coating area 203 .

[0082] In the present embodiment, the thickness of the positive electrode material layer 205 is 120 μm, and the positive electrode material layer 205 is composed of the following components in mass percentage: nickel cobalt lithium manganese oxide 92%, conductive agent superconducting carbon (Super-P) 2 %, conductive graphite 1%, carbon nanotubes 1.5%, binder polyvinylidene fluoride 3.5%. The negative electrode current collector adopts a copper foil with a thickness of 9 μm, and the thic...

Embodiment 3

[0085] combine Figure 1-Figure 3 , a kind of soft package ternary power battery of this embodiment, its structure is basically the same as that of Embodiment 1, the main difference is that: in this embodiment, the thickness of the positive electrode material layer is 113 μm, and the positive electrode material layer 205 is composed of the following mass The percentage composition of the components: 91% nickel cobalt lithium manganate, 4% superconducting carbon, 1.5% conductive graphite, 2% carbon nanotubes, and 1.5% polyvinylidene fluoride. The negative electrode current collector adopts a copper foil with a thickness of 8 μm, and the thickness of the negative electrode material layer is 124 μm. The negative electrode material layer is composed of the following components in mass percentage: 91% of hard carbon material, 2% of conductive carbon black, and 2% of conductive graphite , styrene-butadiene rubber 4%, sodium carboxymethyl cellulose 1%.

[0086] The preparation metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com