Assembled prestressed carbon fiber plate tensioned anchorage system, and anchorage method thereof

A carbon fiber board, prestressed technology, used in building maintenance, structural elements, building components, etc., can solve the problems of low strength, large weight, easy to corrode, etc., to achieve stable quality performance, high reuse rate, and small headroom impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

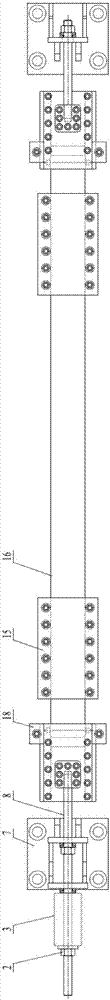

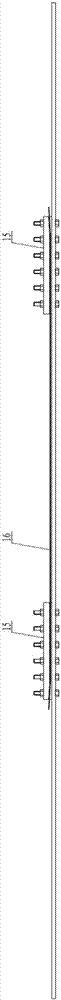

[0074] An assembled prestressed carbon fiber plate tension anchoring system and its anchoring method in this embodiment are shown in the figure, and the I-beam is reinforced against bending to improve the bending bearing capacity of the original member. The installation position of the anchorage is on the lower flange plate of the steel beam 1. The tension anchor system includes outer lock nut 2, through-hole jack 3, spherical washer I-4, inner lock nut 5, spherical washer II-6, reaction frame 7, threaded rod 8, anchor cover 9, Anchor base plate 10, wedge splint 11, steering block 12, pin 13, steering block pressing plate 14, anchoring plate 15, carbon fiber plate 16, and anchoring rail seat 18. The fixed-end anchor 17 has basically the same overall structure and accessory names as the tension-end anchor.

[0075] The anchor cover plate 9 and the bottom plate 10 are formed by precision casting of ductile iron, and the two are connected as a whole by 10 M10 bolts to form the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com