Inserting plate type welding through node

A kind of intersecting node, plug-in technology, applied in the direction of construction, building structure, etc., can solve the problems of strict manufacturing process requirements, long construction period and high cost, and achieve the effect of shortening construction period, convenient construction and reducing construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

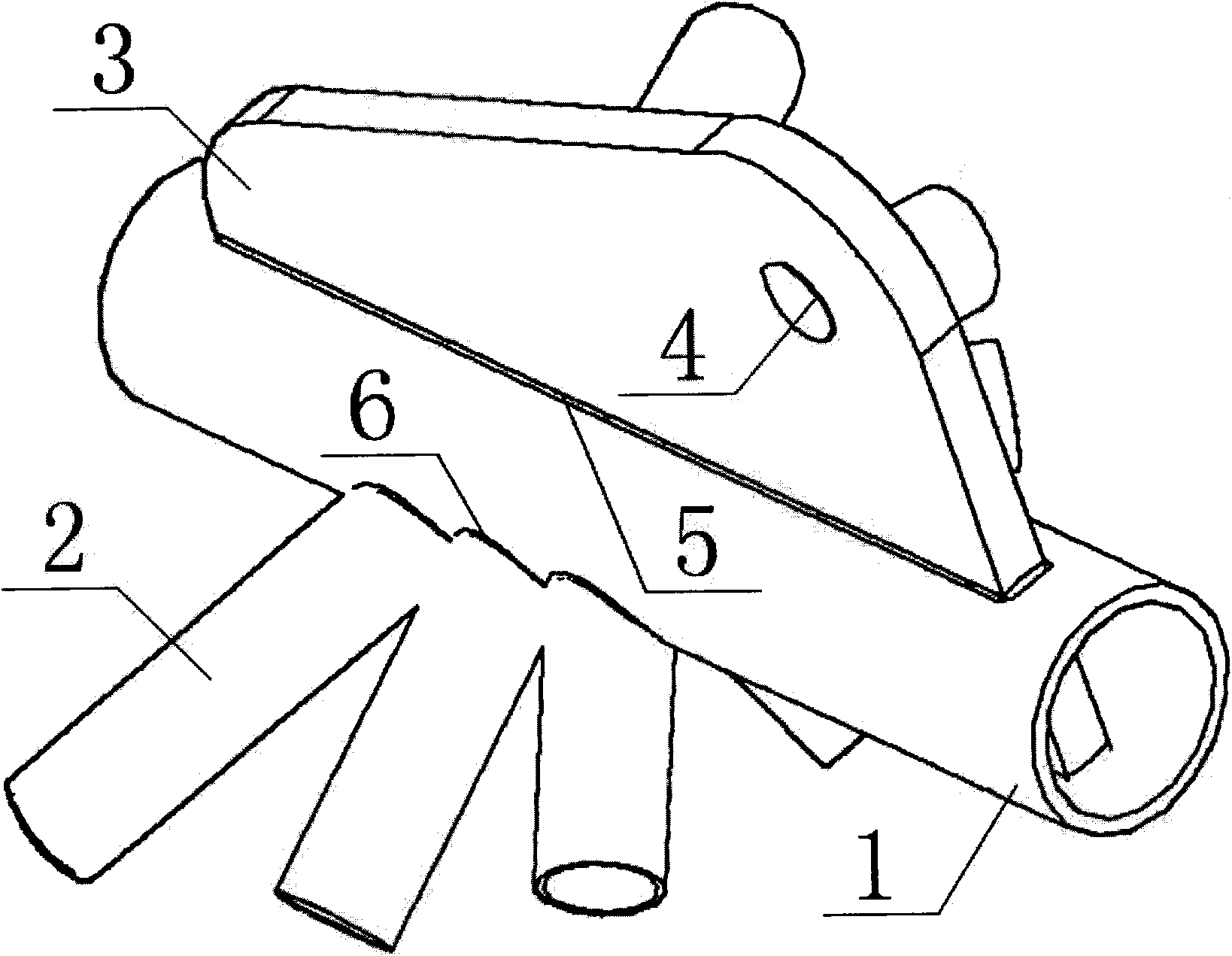

[0019] Embodiment one: if Figure 1-4 As shown, the plug-in welded intersecting joint includes a main pipe 1, a branch pipe 2 and an ear plate 3. The main pipe 1 is made of a round steel pipe, the branch pipe 2 is made of a round steel pipe, and the ear plate 3 is made of a solid steel plate. The main pipe 1 is provided with two grooves up and down. The ear plate 3 is inserted into the main pipe 1 through the groove, and is welded with the main pipe 1 by a penetration weld 5; the branch pipe 2 is connected with the main pipe 1 by a first fillet weld 6; the ear plate 3 is provided with a pin hole 4, and the pin shaft Hole 4 is circular hole or oval hole, and the size of bearing pin hole 4 is slightly larger than the bearing pin size of connecting dragline, so that install;

Embodiment 2

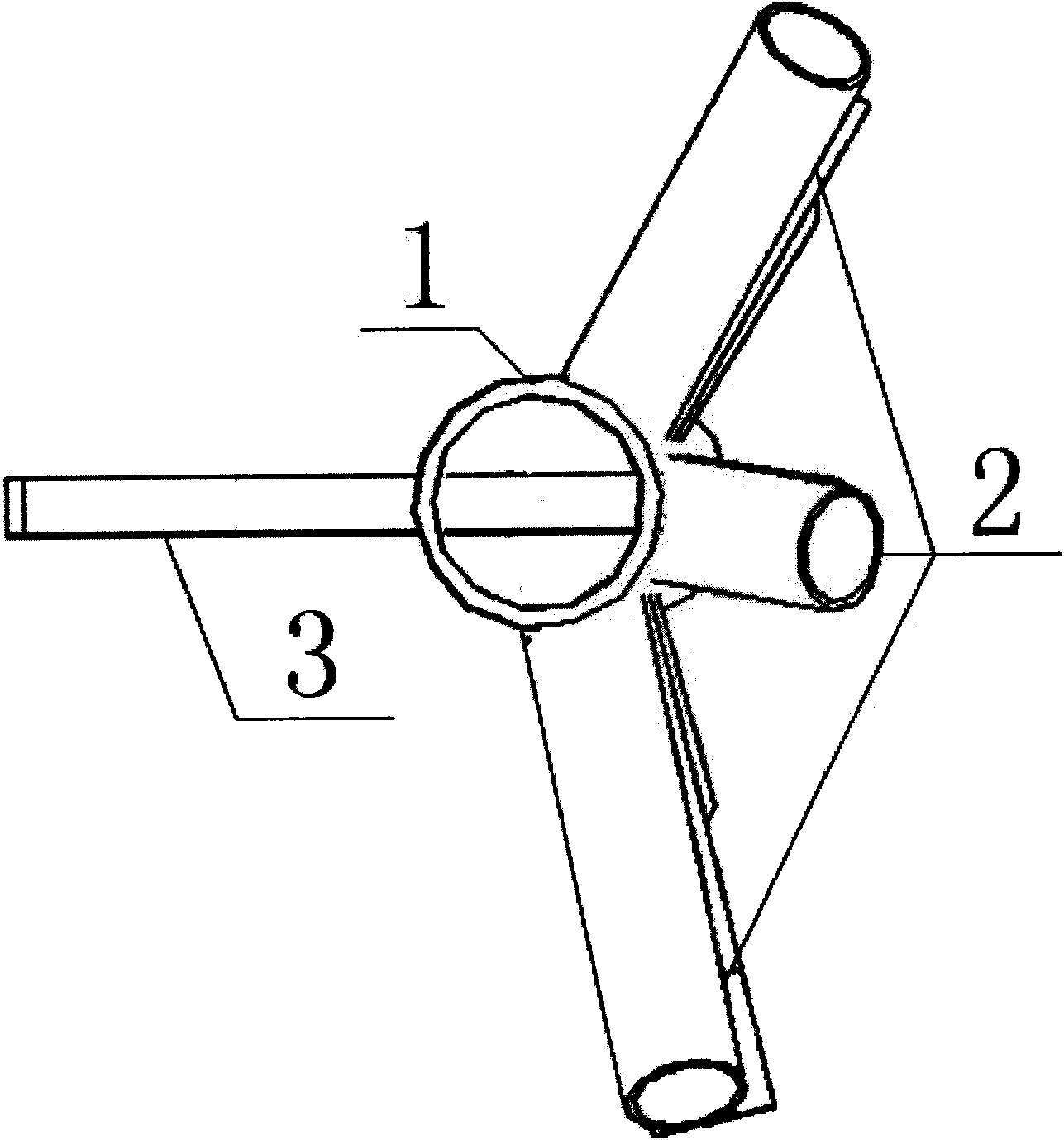

[0020] Embodiment two: if Figure 5 As shown, the difference from Embodiment 1 is that two ear plates 3 are provided, the middle row of branch pipes 2 is canceled, and two rows of branch pipes 2 are arranged in total, so as to facilitate the connection of drag cables on the upper and lower sides of the main pipe, and the two parts inserted into the main pipe. 3 common ear plates.

Embodiment 3

[0021] Embodiment three: as Figure 6 As shown, the difference from the embodiment is that a sleeve 8 is arranged outside the main pipe 1 to strengthen the structure, which is suitable for the situation where the structure is under a large force. The two ends of the sleeve 8 and the main pipe 1 pass through the second fillet weld 9 connected to form a laminated pipe, the lug plate 3 and the laminated pipe are connected by penetration welds, and the branch pipe 2 and the casing 8 are connected by fillet welds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com