Glazed hollow bead fire retardant board and fire retardant heat insulation structure

A technology of vitrified microbeads and fire-resisting boards, which is applied in the field of building materials and building structures, can solve the problem that the thickness of the outer wall fireproof layer cannot meet the fire protection requirements, the bonding between the thermal insulation layer and the fireproof layer is not firm, and the vitrified The high density of the bead mortar layer can achieve the effect of high incombustibility, saving raw materials and high flexural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

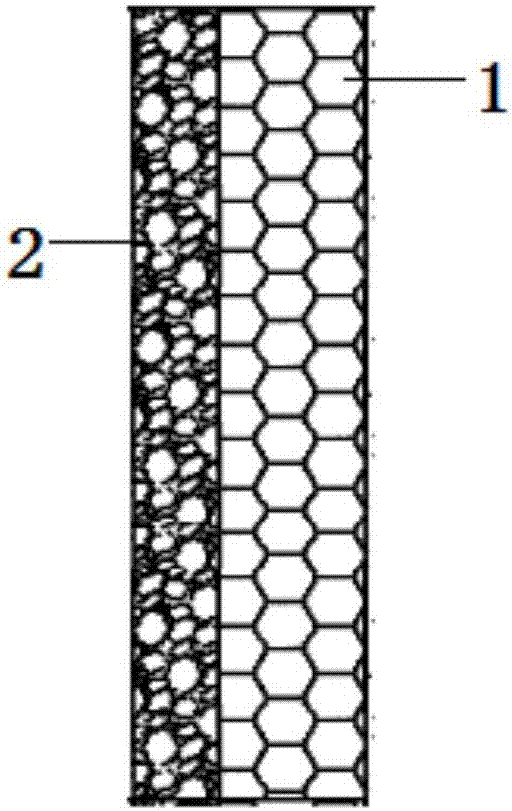

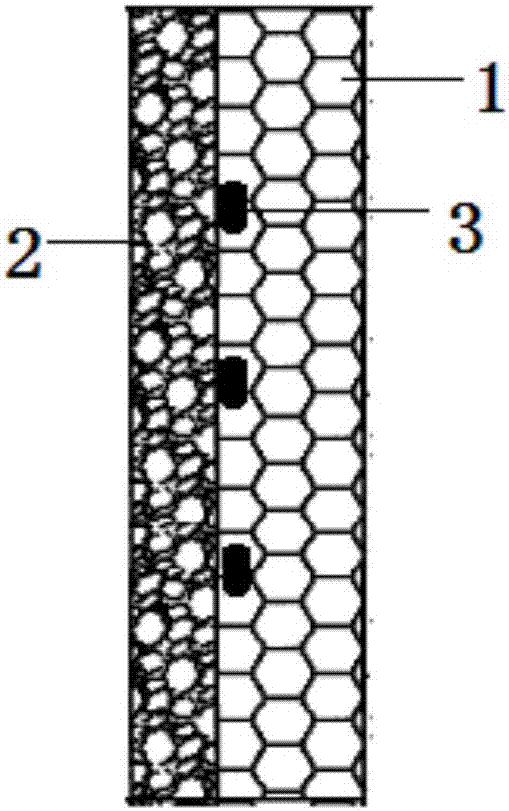

Image

Examples

preparation example Construction

[0023] The present invention also provides a preparation method for the above-mentioned vitrified microbead fire retardant board, which includes the following steps: uniformly mixing the vitrified microbeads with the binder; compacting and smoothing the vitrified microspheres in a flat mold, and the compression ratio is 1:2-1: 3. The time is 10-60 minutes; heating and forming, the heating temperature is 350°C-650°C, and the heating time is 10-60 minutes.

[0024] The vitrified microbead fire retardant board has the following excellent properties: (1) light density, at 300kg / m 3 Below; (2) Low thermal conductivity, below 0.08W / (m·K), preferably below 0.06W / (m·K); (3) It can be well compounded with any other thermal insulation board with a thermal conductivity of 5 cm or more ; (4) easy handling and construction; and (5) high strength.

[0025] In the preparation process of the vitrified microbead fire retardant board proposed by the present invention, there is no need for dryi...

Embodiment 1

[0035] Preparation of vitrified microbead fire retardant board:

[0036] 1) Prepare raw materials: vitrified microbeads (bulk density3 Vitrified microbeads account for 5vol%, and the bulk density is 80-120kg / m 3 Vitrified microbeads account for 35vol%, bulk density>120kg / m 3The vitrified microspheres account for 60vol%) 95 parts; binder (sodium silicate, sodium silicate and calcium silicate, or the mixture of sodium silicate and calcium silicate and calcium oxide) 5 parts; binder in aqueous solution The form is added, wherein the content of solid component is 5 parts;

[0037] 2) The raw materials are mixed evenly;

[0038] 3) The raw material is placed in a flat mold and compacted and smoothed, the compression ratio is 1:2.5, and the time is 30 minutes;

[0039] 4) Place the mold with the raw materials in a heating device to heat and set the shape, the heating temperature is 550° C., and the heating time is 20 minutes.

[0040] It has been determined that the density of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com