Antibacterial fiber yarn

An antibacterial fiber and yarn technology, applied in the textile field, can solve the problems of spinnability and poor skin affinity, and achieve the effects of good antibacterial performance, excellent antibacterial performance and excellent deodorant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The blending ratio of the antibacterial yarn, antibacterial fiber: cotton or nylon: bamboo charcoal fiber = 45:45:10, through the processes of opening and cleaning, wool, carding, drawing, roving, spun yarn and other processes to make 40 s yarn.

[0015] The antibacterial fiber is selected from CN102720057B and CN103266473B synthetic antibacterial fiber.

[0016] Based on the Candidate List of Substances of Very High Concern (according to EU REACH Regulation No. 1907 / 2006) published by the European Chemicals Agency as of December 17, 2014, screening tests were performed on 161 substances of very high concern (SVHC). Analyzed by ICP‐OES, UV‐VIS, GC‐MS, HPLC‐DAD / MS and colorimetric methods. The results are shown in Table 1:

[0017] Table 1

[0018]

Concentration%

SVHCs in the Candidate List for all tests

ND

[0019] The 161 substances of very high concern include 4,4-diaminodiphenylmethane, anthracene, cobalt dichloride, diarsenic trioxide...

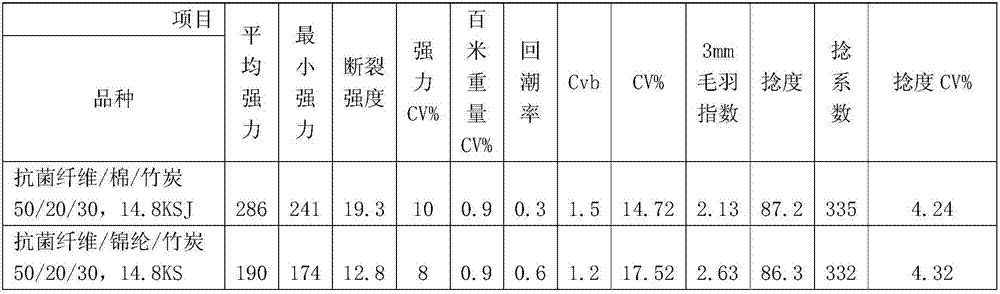

Embodiment 2

[0030] The blending ratio of the antibacterial yarn is antibacterial fiber: viscose fiber: bamboo charcoal fiber 60:20:20, which is made into 40% through the processes of opening and cleaning, wool blending, carding, drawing, roving, and spun yarn. s yarn. Antibacterial cloth is woven from antibacterial yarn.

[0031] The antibacterial fiber is selected from the antibacterial fiber synthesized by CN103266473B and CN103835124B.

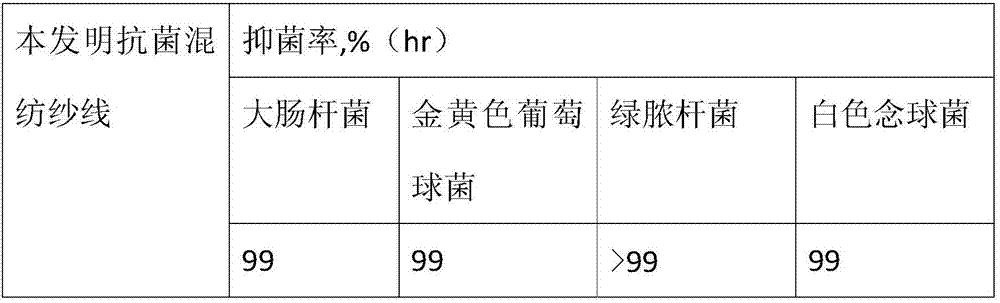

[0032] The antibacterial performance test of antibacterial knitted fabrics adopts FZ / T 73023‐2006 antibacterial knitted fabrics, shock method, and the results are shown in Table 5:

[0033] table 5

[0034]

[0035]

[0036] Antibacterial knitted fabric multiple integrity skin irritation test, "Disinfection Technical Specifications" Ministry of Health (2002 edition) 2.3.3.3.3, the results are shown in Table 6:

[0037] Table 6

[0038]

[0039]

[0040] According to GB / T8629 washing 10, 30, 50 times, the antibacterial performance of ant...

Embodiment 3

[0048] Described antibacterial yarn blending ratio, antibacterial fiber: blended fiber (cotton, dacron, modal): bamboo charcoal fiber=50: (10:10:10): 20, through opening and cleaning, wool, carding, drawing, Made from roving, spun yarn and other processes 40 s Yarn, made of antibacterial socks through antibacterial yarn processing.

[0049] The antibacterial fiber is selected from the antibacterial fiber synthesized by CN101879466B and CN102720057B.

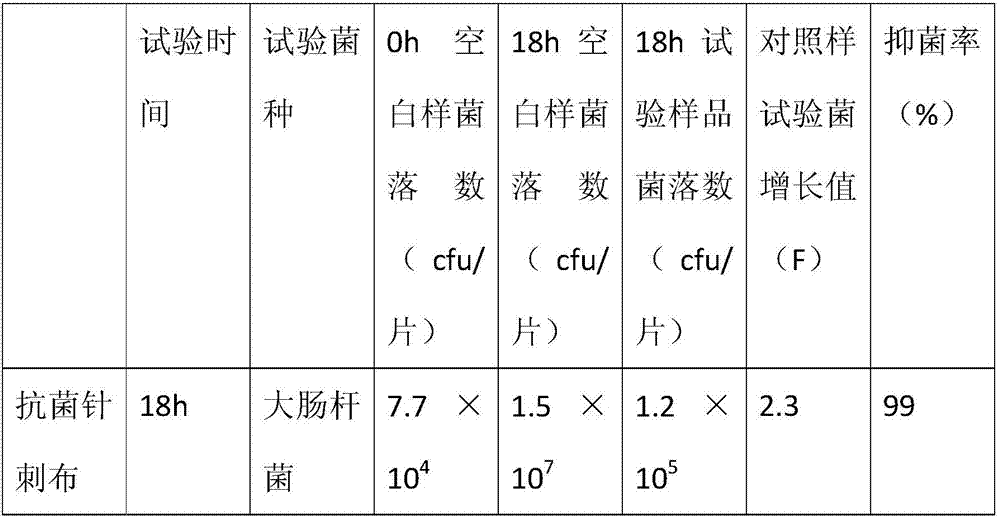

[0050]Antibacterial socks antibacterial test, using GB / T20944.2-2007 Evaluation of antibacterial properties of textiles Part II: Absorption method, the results are shown in Table 9:

[0051] Table 9

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com