Graphene crystal composite polylactic acid antibacterial material and preparation method thereof

A technology of alkene polylactic acid and composite material, applied in the field of graphene crystal composite polylactic acid antibacterial material and preparation thereof, can solve the problems of uneven combination of antibacterial composite and polylactic acid, poor antibacterial effect, poor antibacterial performance, etc. Suitable for industrial production, enhanced antibacterial effect, durable antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

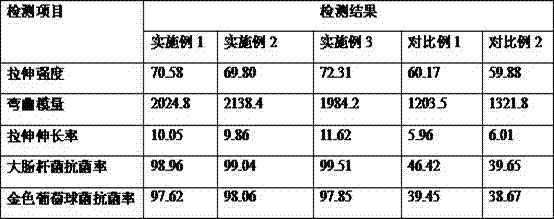

Examples

Embodiment 1

[0049] The first step: preparation of graphene antibacterial composite

[0050] (1) Take 10g of titanium dioxide with a particle size of 50-80nm and 1g of zinc oxide with a particle size of 20-50nm, pour them into the agate ball mill cylinder of the ball mill, add 11ml of water, and perform ball milling at a speed of 600rpm for 4 hours, and then divide into three batches Add 10g of nano-silver powder with a particle size of 25nm, and then add 10ml of water, and continue ball milling for 3h. Stop ball milling, and dry at about 50°C under a vacuum of 0.2MPa to obtain an antibacterial mixture;

[0051] (2) Dissolve 210g of graphene in 42L of ethanol, ultrasonically oscillate at 100KW until dissolved, and prepare a graphene solution; add 5% sodium hydroxide solution, disperse with ultrasound, then add 2100g of chloroacetic acid, and continue the reaction for 3 hours. Centrifuge at a rate of 500rpm for 1h, and dry at 60°C for 5h under a vacuum of 0.2MPa to obtain surface-modified ...

Embodiment 2

[0057] The first step: preparation of graphene antibacterial composite

[0058] (1) Take 10g of titanium dioxide with a particle size of 10-30nm and 0.5g of zinc oxide with a particle size of 50-80nm, pour them into the agate ball milling cylinder of the ball mill, add 10ml of water, and perform ball milling at a speed of 800rpm for 3 hours, then divide into three Add 10g of nano-silver powder with a particle size of 50nm in batches, then add 10ml of water, and continue ball milling for 5h. Stop ball milling, and dry at about 50°C under a vacuum of 0.5MPa to obtain an antibacterial mixture;

[0059] (2) Dissolve 600g of graphene in 40L of ethanol, ultrasonically vibrate at 250KW until dissolved, and prepare a graphene solution; add 5% potassium hydroxide solution, disperse with ultrasound, then add 3000g of chloroacetic acid, and continue the reaction for 5 hours. Centrifuge at 800rpm speed for 1h, and dry at 60°C for 5h at a vacuum of 0.3MPa to obtain surface-modified graphe...

Embodiment 3

[0065] The first step: preparation of graphene antibacterial composite

[0066] (1) Take 10g of titanium dioxide with a particle size of 30~50nm and 0.8g of zinc oxide with a particle size of 10~30nm, pour them into the agate ball mill cylinder of the ball mill, add 11ml of water, and perform ball milling at a speed of 700rpm for 5h, then divide into three Add 10g of nano-silver powder with a particle size of 10nm in batches, then add 10ml of water, and continue ball milling for 5h. Stop ball milling, and dry at about 50°C under a vacuum of 0.3MPa to obtain an antibacterial mixture;

[0067] (2) Dissolve 400g of graphene in 40L of ethanol, add 80g of non-ionic surfactant sorbitol ester, and ultrasonically vibrate at a frequency of 200KW until dissolved to prepare a graphene solution; add 10% sodium hydroxide solution and disperse it with ultrasound. Then add 3000g of chloroacetic acid, continue to react for 5 hours, centrifuge at 800rpm for 1h, and dry at 60°C for 5h at a vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com