Method for treating oil-containing waste water of lifting type membrane bioreactor system

A membrane bioreactor and bioreactor technology, applied in the field of water treatment, can solve problems such as complex structure, difficult cleaning, membrane pollution, etc., and achieve the effect of simple and stable structure and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

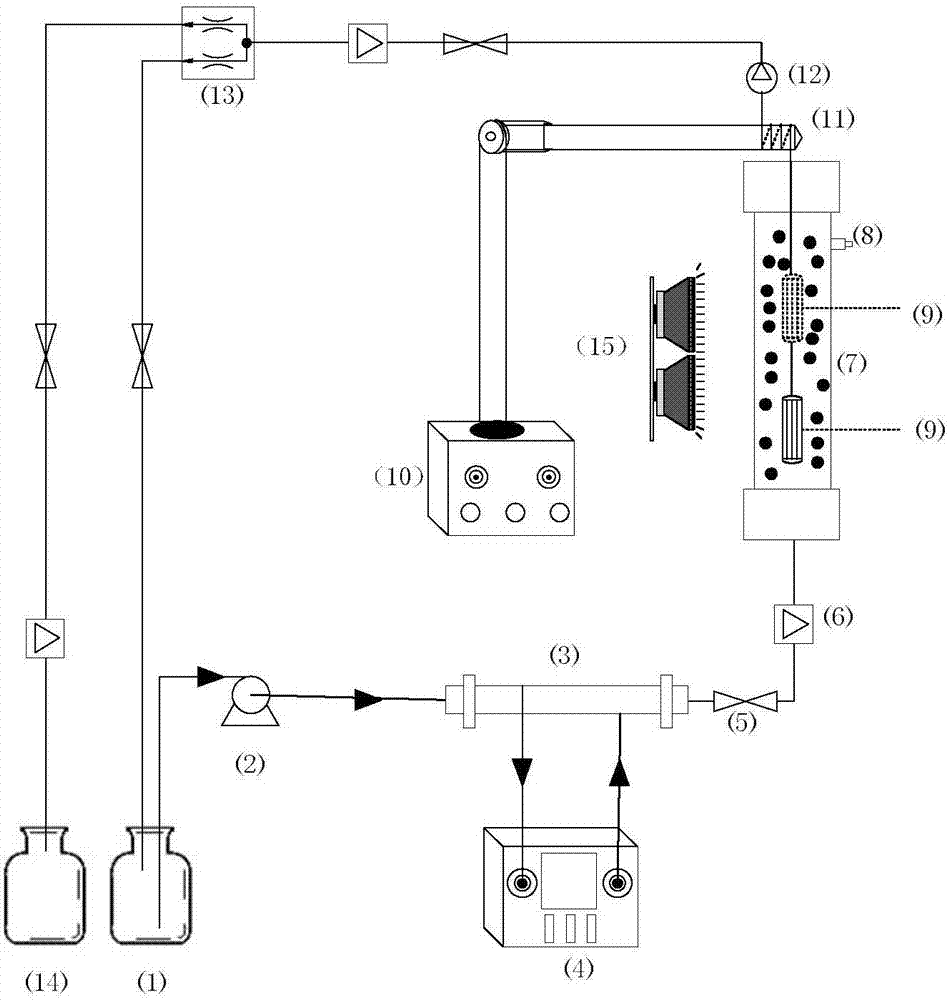

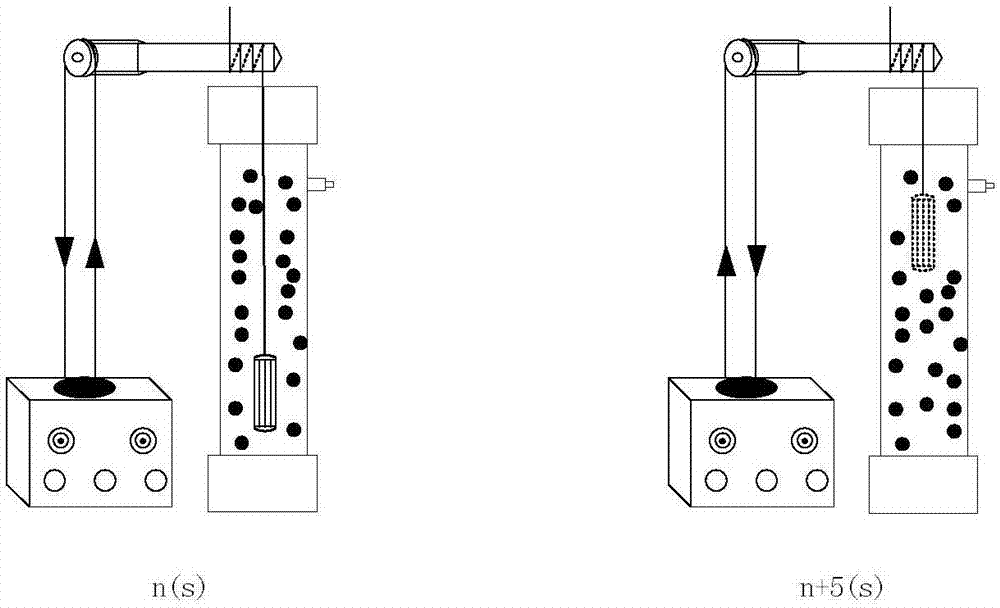

Method used

Image

Examples

Embodiment 1

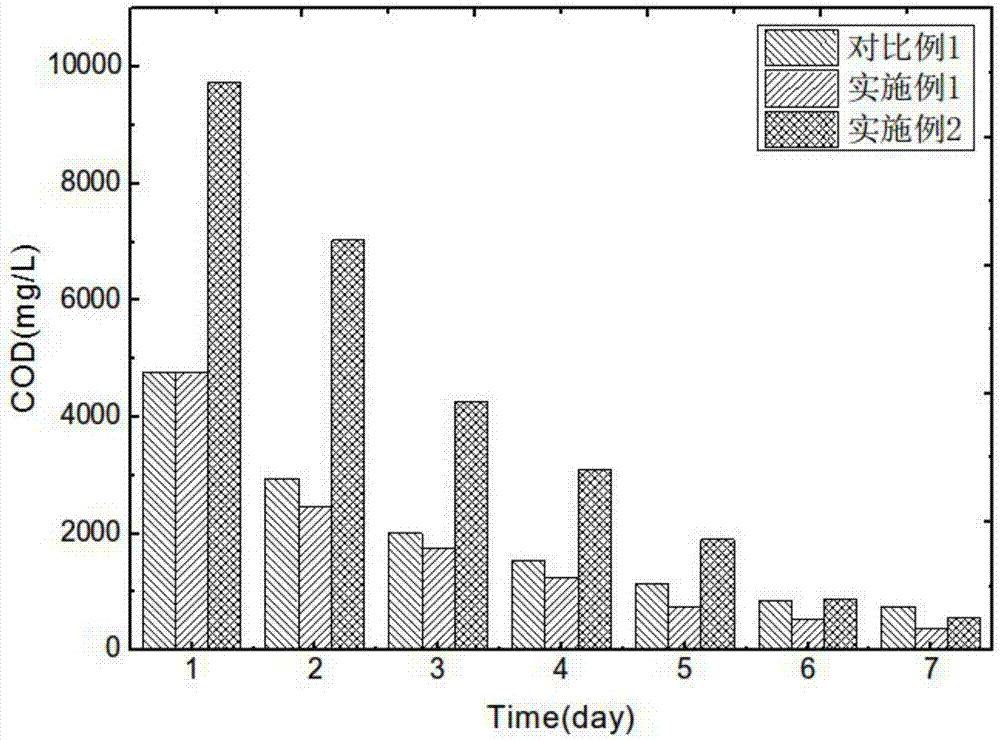

[0034] The industrial refinery wastewater is treated by using the lifting membrane bioreactor system, and the change of the water quality (COD) in and out of the membrane and the change of the membrane flux during the operation of the system are measured.

[0035] Water quality indicators of industrial refinery wastewater: COD value is about 4000-5000mg / L, salinity is 2%-3%, and the type of oil is slick oil.

[0036] The operating conditions of the system are: the reactor volume is 2.8L, the PVDF microfiltration membrane is used, the transmembrane pressure is 0.2-0.3MPa, and the initial absorbance of Pseudomonas aeruginosa NY3 is OD 600 0.27, the mass ratio of the added bacteria solution to the filler is 1:5, the reactor temperature is 30-31°C, the light intensity is 2000-3000lux, the flow rate is controlled at 100-110ml / h; the water retention time is 34-36h.

[0037] Depend on image 3 It can be seen that the lifting membrane bioreactor system has a good treatment effect on ...

Embodiment 2

[0044] The petroleum wastewater was treated by a lifting membrane bioreactor system, and the change of membrane effluent quality (COD) and the change of membrane flux during system operation were measured.

[0045] Water quality indicators of petroleum wastewater: COD is 8000-12000mg / L, salinity is 3%-5%, and the oil type is emulsified oil;

[0046] The operating conditions of the system are: consistent with Embodiment 1;

[0047] Depend on image 3 It can be seen that the lifting membrane bioreactor system also has a good treatment effect on petroleum wastewater, and the COD removal rate is basically maintained above 93%. Figure 4 It can be seen that the flux of the lifting membrane module is stable and maintains 18.7L / m 2 h bar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com