Waterproof coiled material forming machine

A waterproofing membrane and molding machine technology, which is applied to other household appliances, flat products, household appliances, etc., can solve the problems of easy pollution of the environment, anti-sticking and non-uniformity, etc., to achieve uniform spraying, good effect, and prevent anti-sticking powder. effect of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

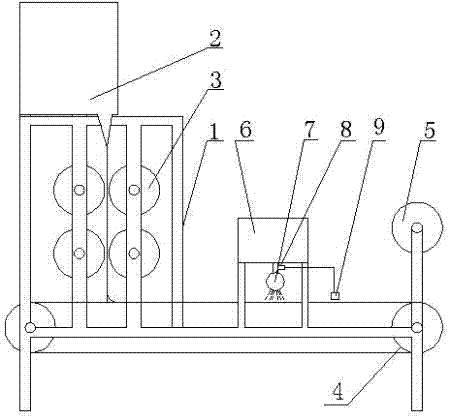

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

[0009] Such as figure 1 As shown, a waterproof coil forming machine includes a forming machine body, the forming machine body has a frame 1, and a hopper 2, a forming roller 3, a conveying device 4 and a coiling device 5 are arranged on the frame, and it is characterized in that: A water tank 6 is also installed on the frame between the forming roll and the coiling device, and the water tank is connected with a spray pipe 7. The spray pipe has a plurality of water spray ports, and the water spray ports face the side edge of the conveying device to the other side. The edge, so that the anti-sticking powder can be placed in the pool, add water and stir, the anti-sticking powder is in a state of mixing with water, and sprayed on the waterproof material, instead of the current anti-sticking powder sprayed directly on these materials, so Just reduce pollution, also have th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com