One-clamping type grinding machine for three-sided right-angular workpieces

A clamping and right-angle technology, which is applied in the direction of grinding machines, grinding bed, grinding machine parts, etc., can solve the problems of inaccurate movement and positioning of workpieces, debris easily affecting processing, and poor processing progress, etc., to achieve reduction Clamping error, simple structure, and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

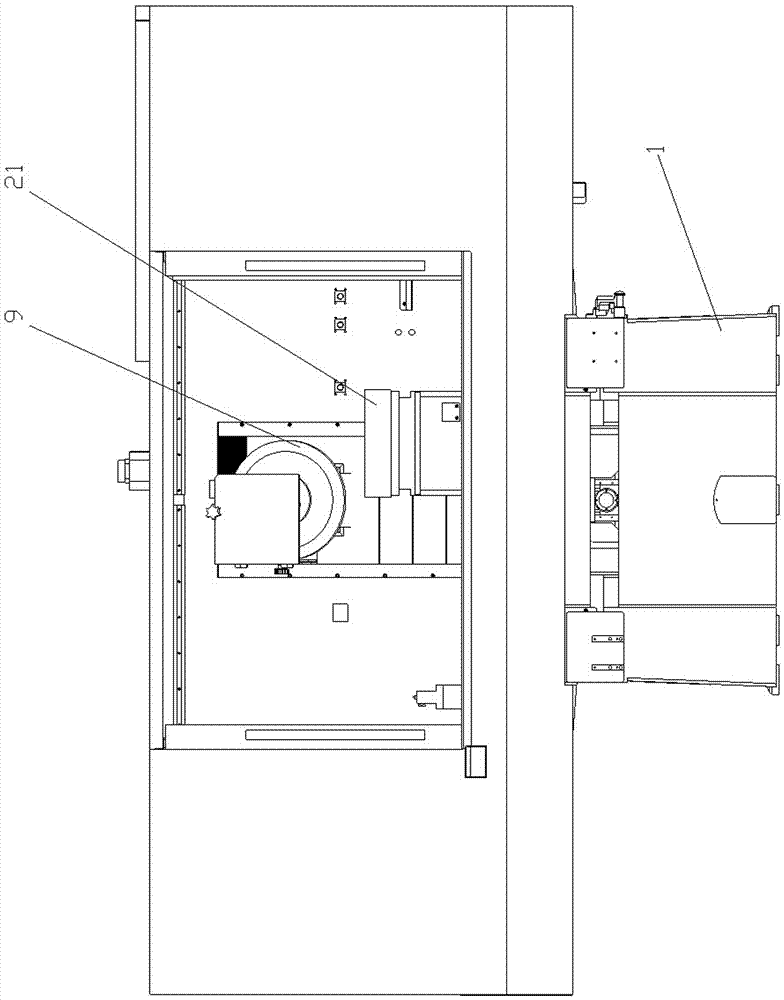

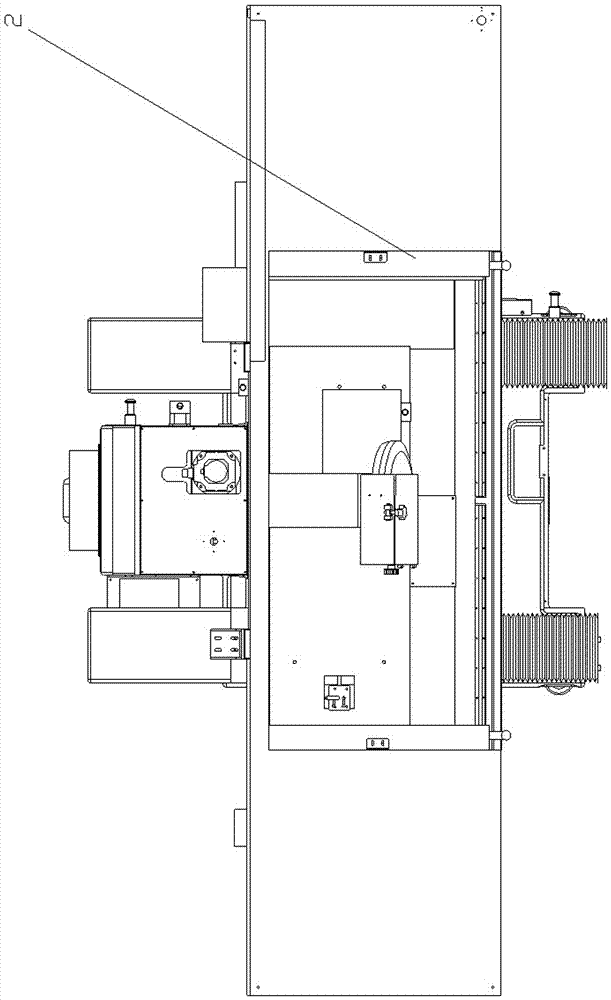

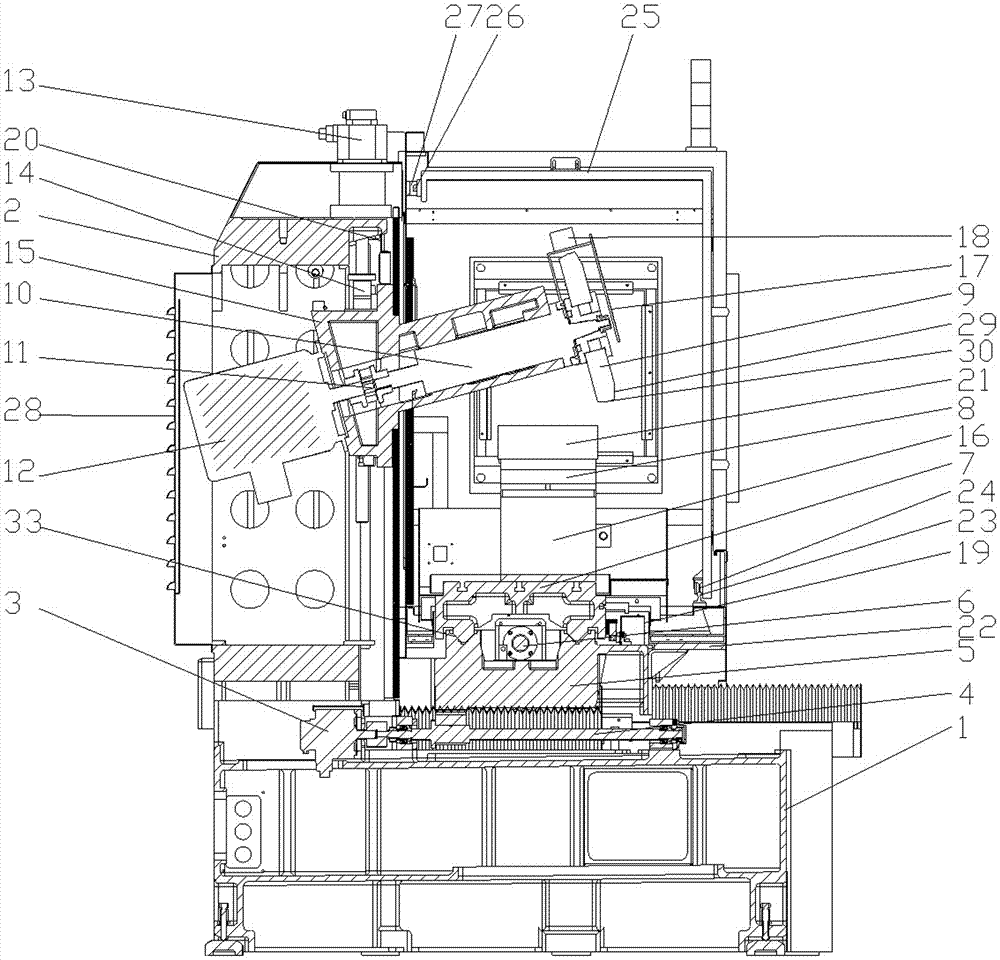

[0024] Embodiment: a kind of one-time clamping type three-sided right-angle grinder of this example, as figure 1 , figure 2 , image 3 , including the main base 1, the upper part of the main base is fixed with an upper frame 2, the lower part of the main base is provided with a front and rear servo motor 3, the front and rear servo motors are connected with front and rear ball screws 4, and the front and rear ball screws are movably connected with front and rear support seats 5 , the front and rear support bases are provided with left and right servo motors, the left and right servo motors are connected with left and right ball screws 6, and the left and right ball screws are movably connected with workbench 7, and the workbench is provided with permanent clips 8 that can clamp three-sided right-angled workpieces 21, A grinding wheel 9 arranged obliquely is arranged above the permanent clip, and the grinding wheel is connected with a main shaft 10, and the main shaft is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com