Plate-shaped part drilling equipment for hardware tool machining

A technology for hardware tools and drilling equipment, which is applied in metal processing equipment, metal processing machinery parts, drilling/drilling equipment, etc. It can solve the problems of cumbersome operation and difficult adjustment of drilling position, and achieve the effect of efficient drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

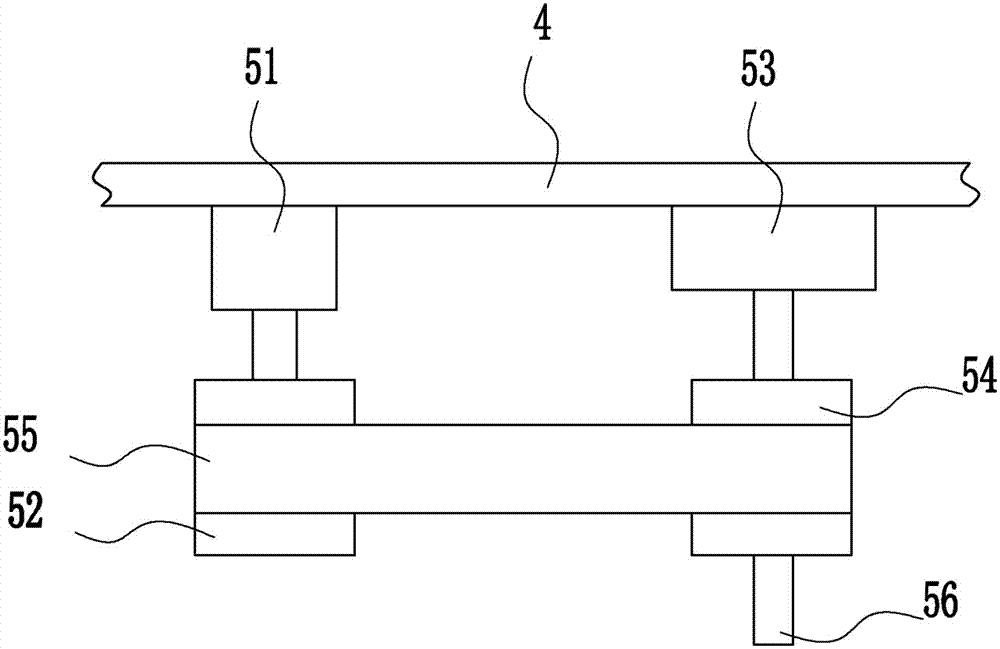

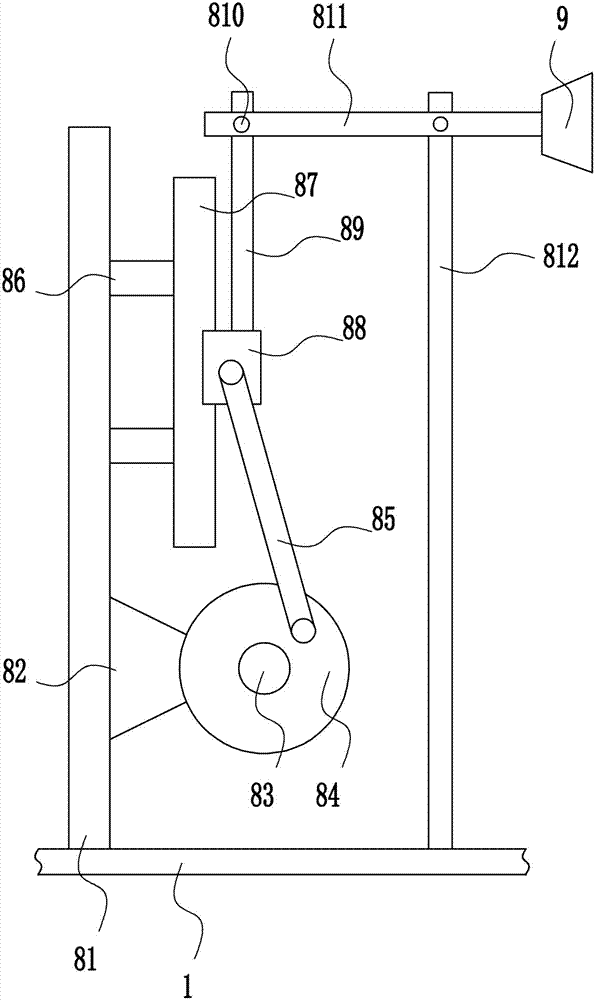

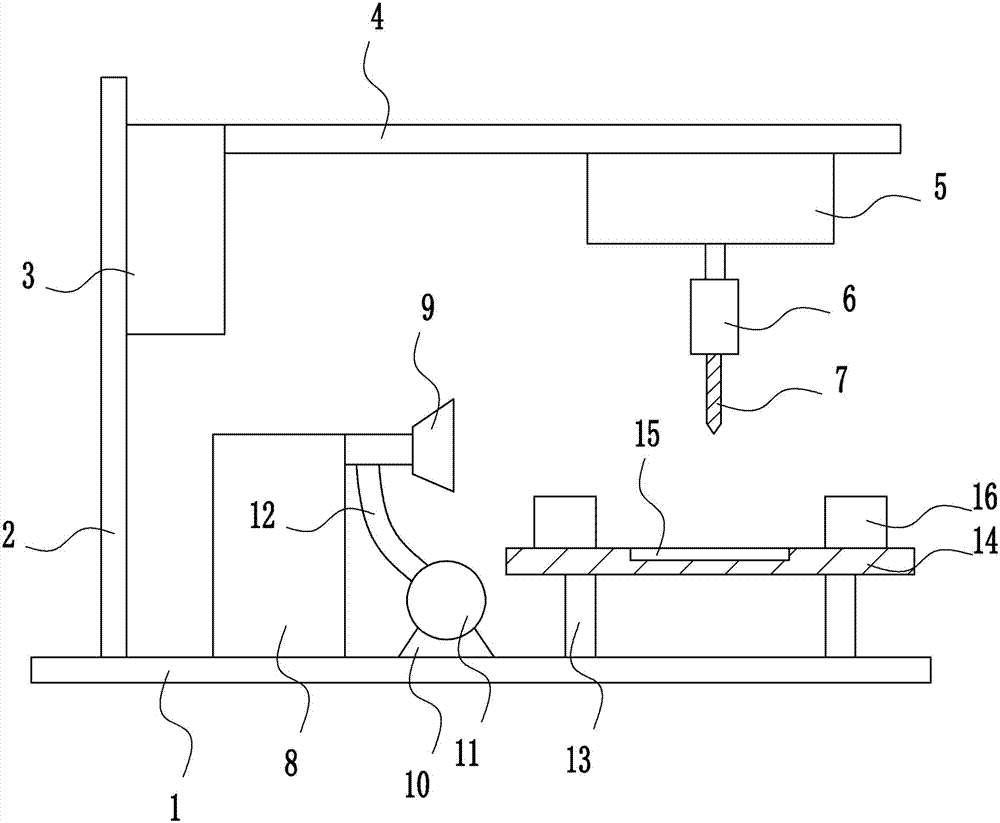

[0036] A kind of drilling equipment for plate-shaped parts for hardware tool processing, such as Figure 1-6 As shown, it includes a bottom plate 1, a left frame 2, a lifting device 3, a first mounting plate 4, a rotating device 5, a tool holder 6, a drill bit 7, a swinging device 8, a spray head 9, a first mounting seat 10, an air pump 11, and a pipeline 12. The first bracket 13, the console 14 and the fixing device 16. The left frame 2 is welded on the left end of the top of the bottom plate 1, the lifting device 3 is welded on the upper right side of the left frame 2, and the first installation plate 4 is welded on the upper right side of the lifting device 3 , the right side of the bottom of the first mounting plate 4 is welded with a rotating device 5, the bottom of the rotating device 5 is welded with a knife sleeve 6, the bottom of the knife sleeve 6 is sleeved with a drill bit 7, the left side of the top of the bottom plate 1 is welded with a swinging device 8, and the ...

Embodiment 2

[0038] A kind of drilling equipment for plate-shaped parts for hardware tool processing, such as Figure 1-6 As shown, it includes a bottom plate 1, a left frame 2, a lifting device 3, a first mounting plate 4, a rotating device 5, a tool holder 6, a drill bit 7, a swinging device 8, a spray head 9, a first mounting seat 10, an air pump 11, and a pipeline 12. The first bracket 13, the console 14 and the fixing device 16. The left frame 2 is welded on the left end of the top of the bottom plate 1, the lifting device 3 is welded on the upper right side of the left frame 2, and the first installation plate 4 is welded on the upper right side of the lifting device 3 , the right side of the bottom of the first mounting plate 4 is welded with a rotating device 5, the bottom of the rotating device 5 is welded with a knife sleeve 6, the bottom of the knife sleeve 6 is sleeved with a drill bit 7, the left side of the top of the bottom plate 1 is welded with a swinging device 8, and the ...

Embodiment 3

[0041] A kind of drilling equipment for plate-shaped parts for hardware tool processing, such as Figure 1-6 As shown, it includes a bottom plate 1, a left frame 2, a lifting device 3, a first mounting plate 4, a rotating device 5, a tool holder 6, a drill bit 7, a swinging device 8, a spray head 9, a first mounting seat 10, an air pump 11, and a pipeline 12. The first bracket 13, the console 14 and the fixing device 16. The left frame 2 is welded on the left end of the top of the bottom plate 1, the lifting device 3 is welded on the upper right side of the left frame 2, and the first installation plate 4 is welded on the upper right side of the lifting device 3 , the right side of the bottom of the first mounting plate 4 is welded with a rotating device 5, the bottom of the rotating device 5 is welded with a knife sleeve 6, the bottom of the knife sleeve 6 is sleeved with a drill bit 7, the left side of the top of the bottom plate 1 is welded with a swinging device 8, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com