In-tunnel rapid turning construction equipment and method for multiple connection channels

A communication channel and construction equipment technology, which is applied in the field of quick-turning construction equipment in tunnels with multiple communication channels, can solve the problems of large manpower consumption, affecting double-sided drilling work, and difficulty in matching the distance between holes and slots, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

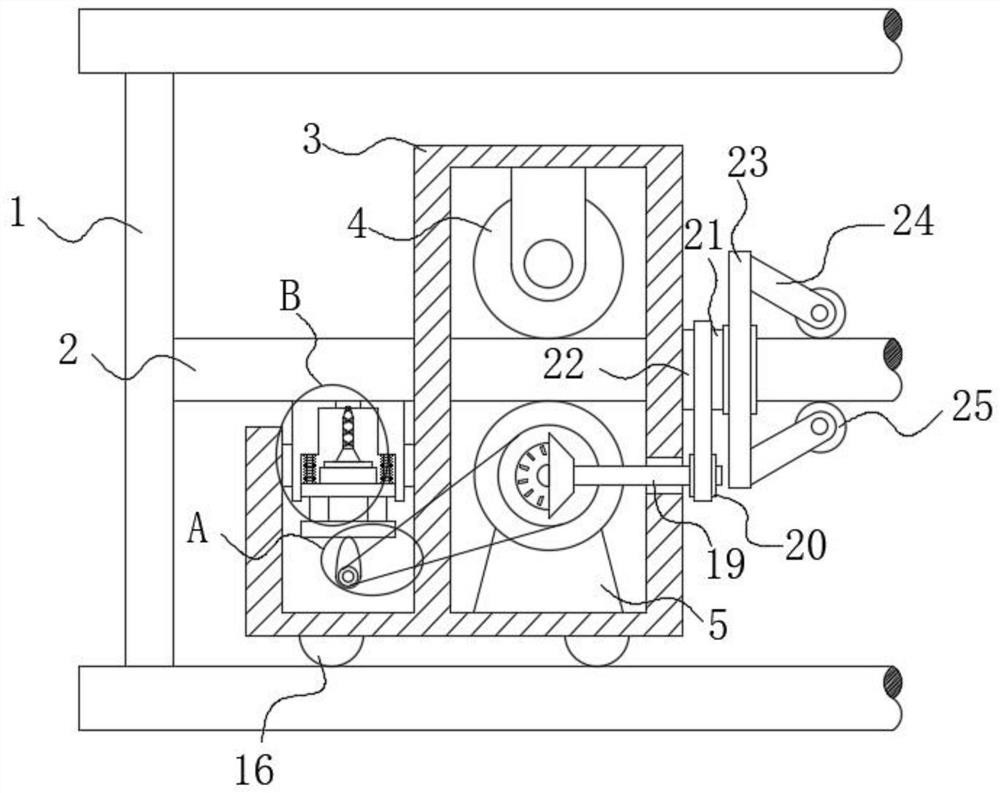

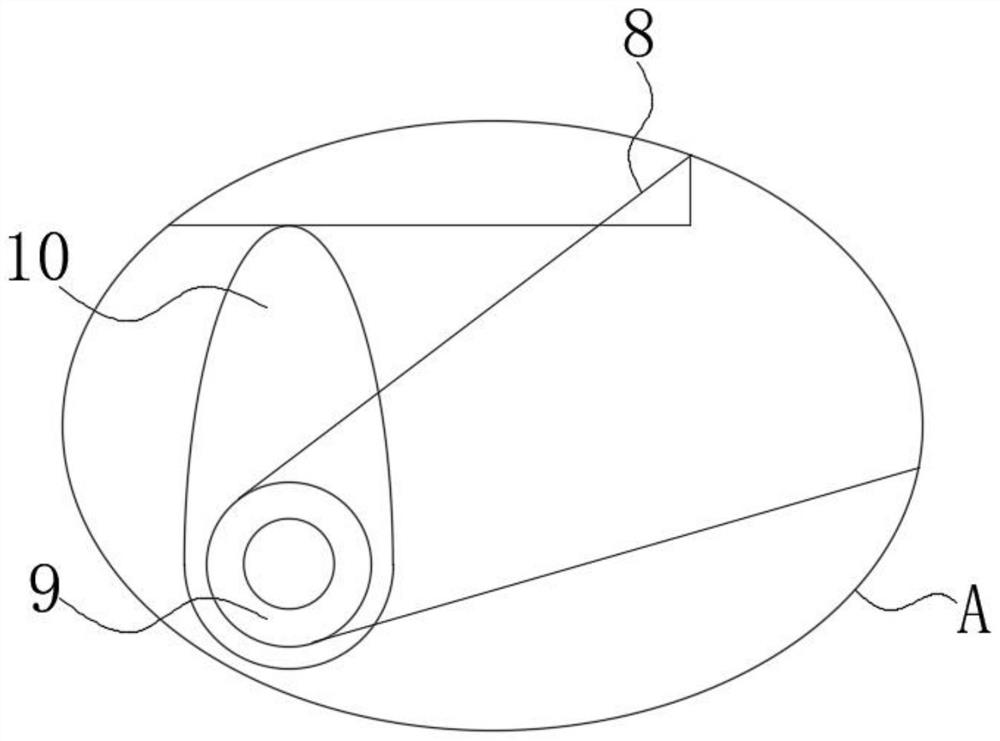

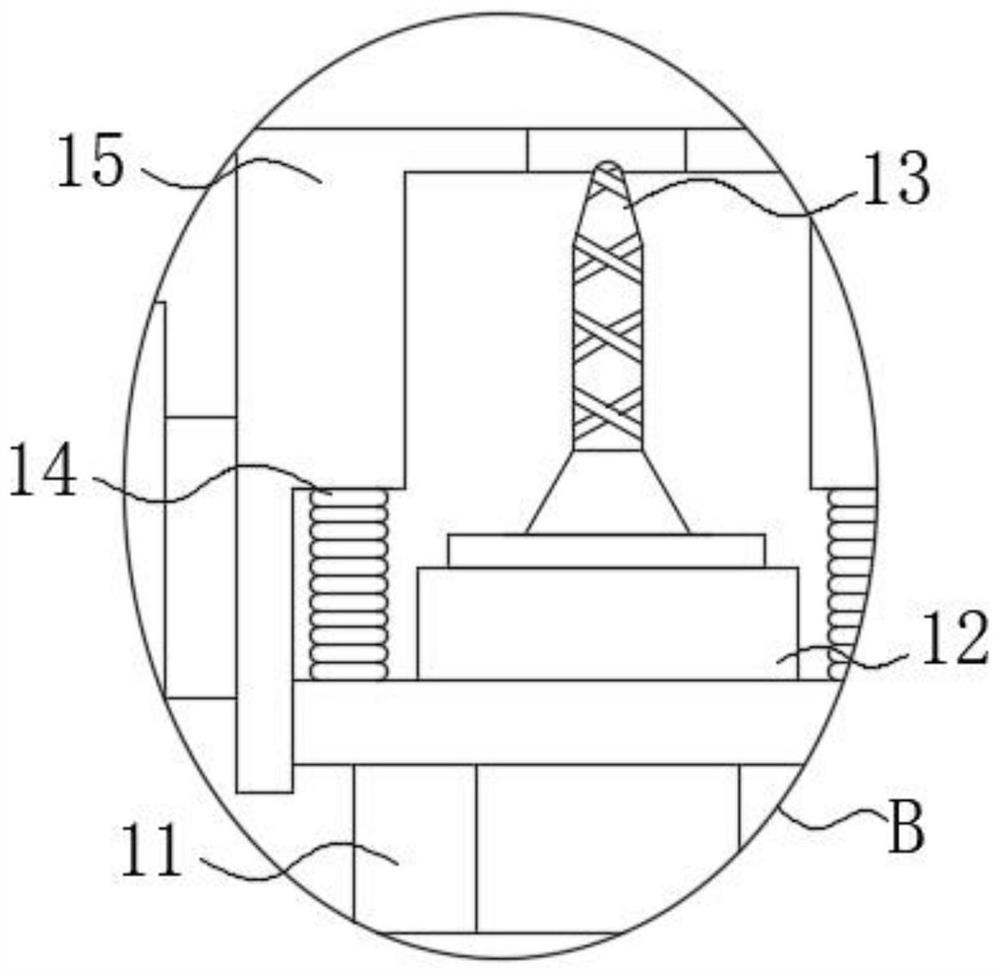

[0032] refer to Figure 1-5 , a construction equipment and method for quick turnaround in tunnels with multiple communication passages, comprising a bracket frame 1, a circular pipe fitting 2, a sleeve frame 3, an upper roller 4 and a driving motor 5, and the round pipe fitting 2 is fixedly connected to the bracket frame 1 On the middle inner wall of the frame, the sleeve frame 3 is slidably connected to the lower inner wall of the bracket frame 1, the upper roller 4 is fixedly connected to the upper inner wall of the bracket frame 1, and the driving motor 5 is fixedly connected to the lower inner wall of the bracket frame 1, and the driving The model of the motor 5 is Y80M1-1, and the front of the drive motor 5 is equipped with a lower roller 6, and the front of the lower roller 6 is fixedly connected with a first pulley 7, and the outer surface of the first pulley 7 is equipped with a transmission mechanism. The front is installed by a traction mechanism.

[0033] The trans...

Embodiment 2

[0042] refer to Figure 6 , when the sleeve frame 3 moves to the side close to the support frame 1, turn the sleeve frame 3 so that the elastic pad 16 on the lower side of the sleeve frame 3 is embedded in the inner side of the upper support frame 1, at this time the drill bit 13 will meet the circular pipe 2 The upper surface is drilled to achieve the effect of double-sided drilling. At this time, the cleaning block 25 is on the rear side of the drilling position, and the waste chips in the drilling process can be cleaned from the outer surface of the circular pipe fitting 2. It facilitates the subsequent installation work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com