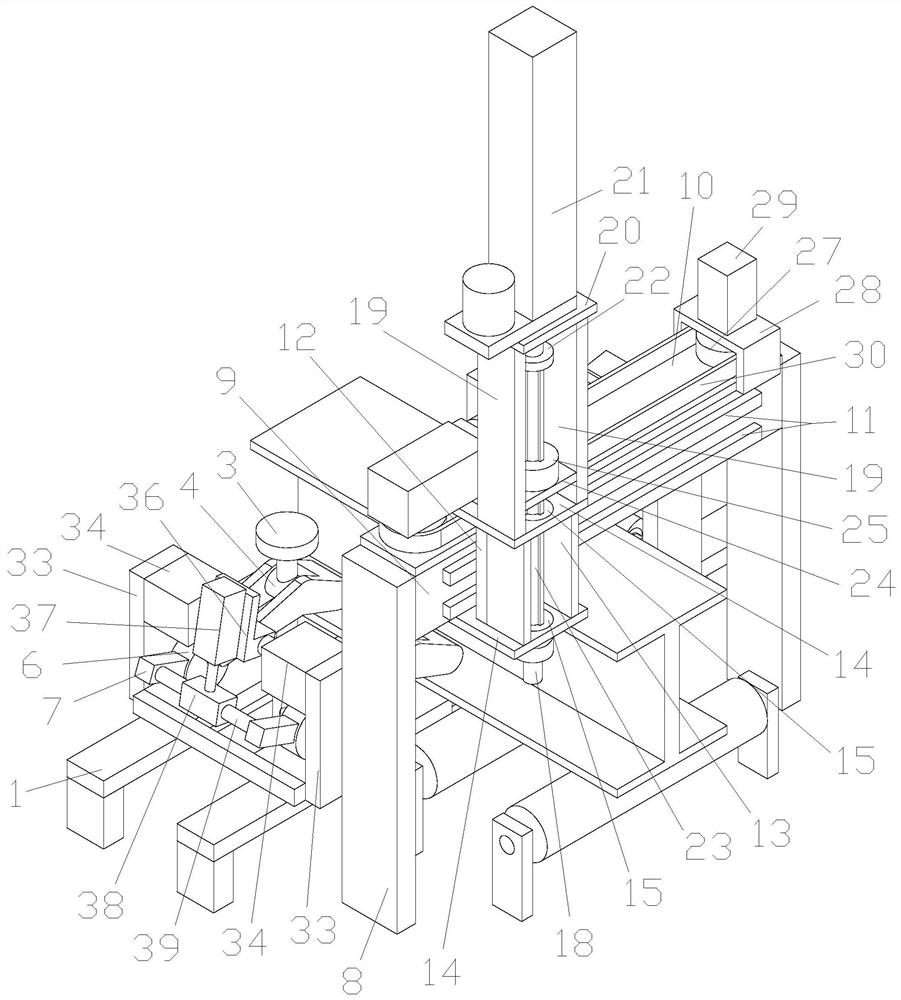

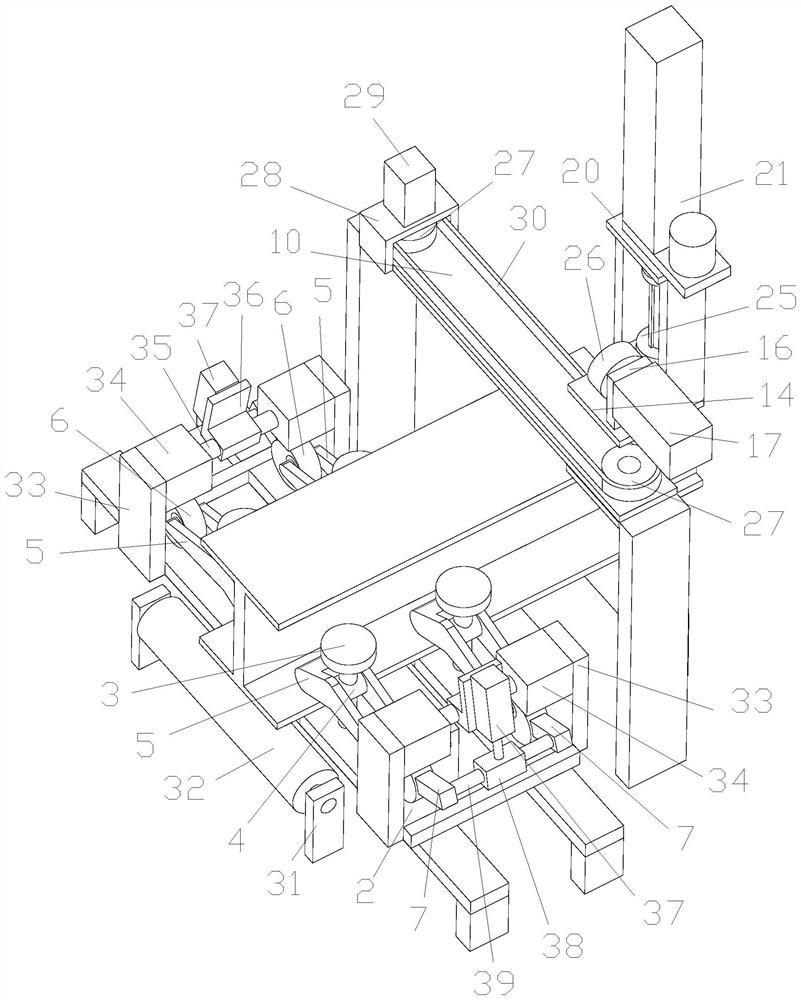

Profile steel punching device

A technology of punching device and section steel, applied in the directions of feeding device, positioning device, storage device, etc., can solve the problems of user inconvenience, affecting the punching efficiency of steel pipe, cumbersome positioning structure, etc., and achieve the effect of preventing bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] Embodiment: a kind of section steel punching device, as Figure 1-Figure 2 As shown, it includes a set of pressing mechanism, punching mechanism and multiple groups of rollers. The pressing mechanism includes two long supports 1 arranged side by side, and a mounting plate is arranged on the two long supports 1. 2. There are pressing parts at both ends of the two mounting plates 2, and the pressing parts on the front side include two third vertical plates 33 and two rotating handles 3, and the two rotating handles 3 are respectively provided with On the two mounting plates 2, the lower ends of the two rotary handles 3 are rotatably connected to the mounting plate 2, and a lifting block 4 is set on the two handles respectively, and the upper rotating blocks of the lifting block 4 are connected There is a pressure plate 5, the lifting block 4 is threadedly connected with the rotary handle 3, and the outer ends of the two pressure plates 5 are respectively hinged with an ec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com