An engraving machine kit for drilling and internal carving

A technology of engraving machine and kit, which is applied in the field of engraving machine kits, can solve the problems of not being able to maintain the natural state of raw materials, and achieve the effect of flexible engraving process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

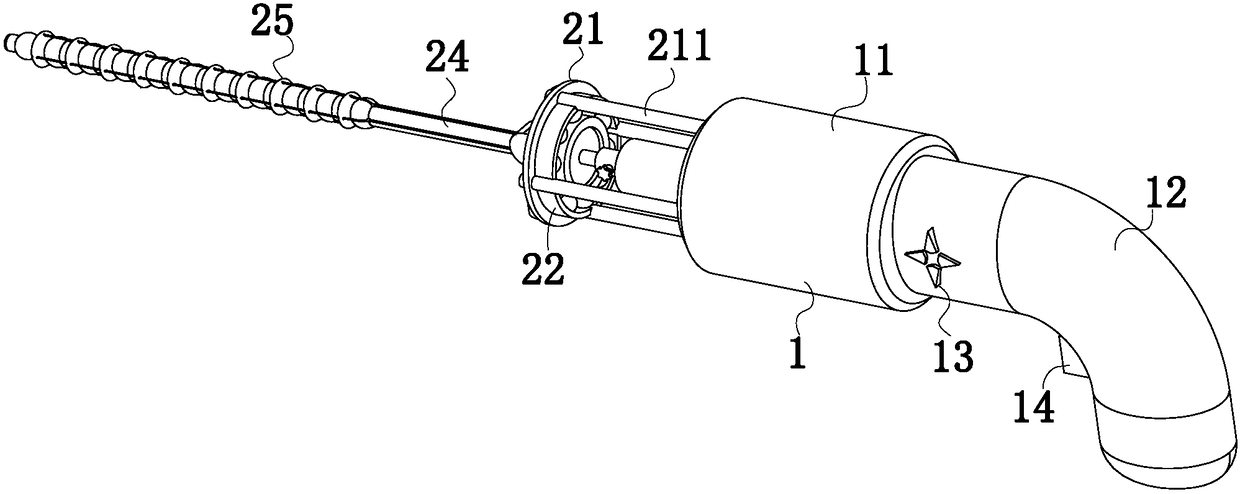

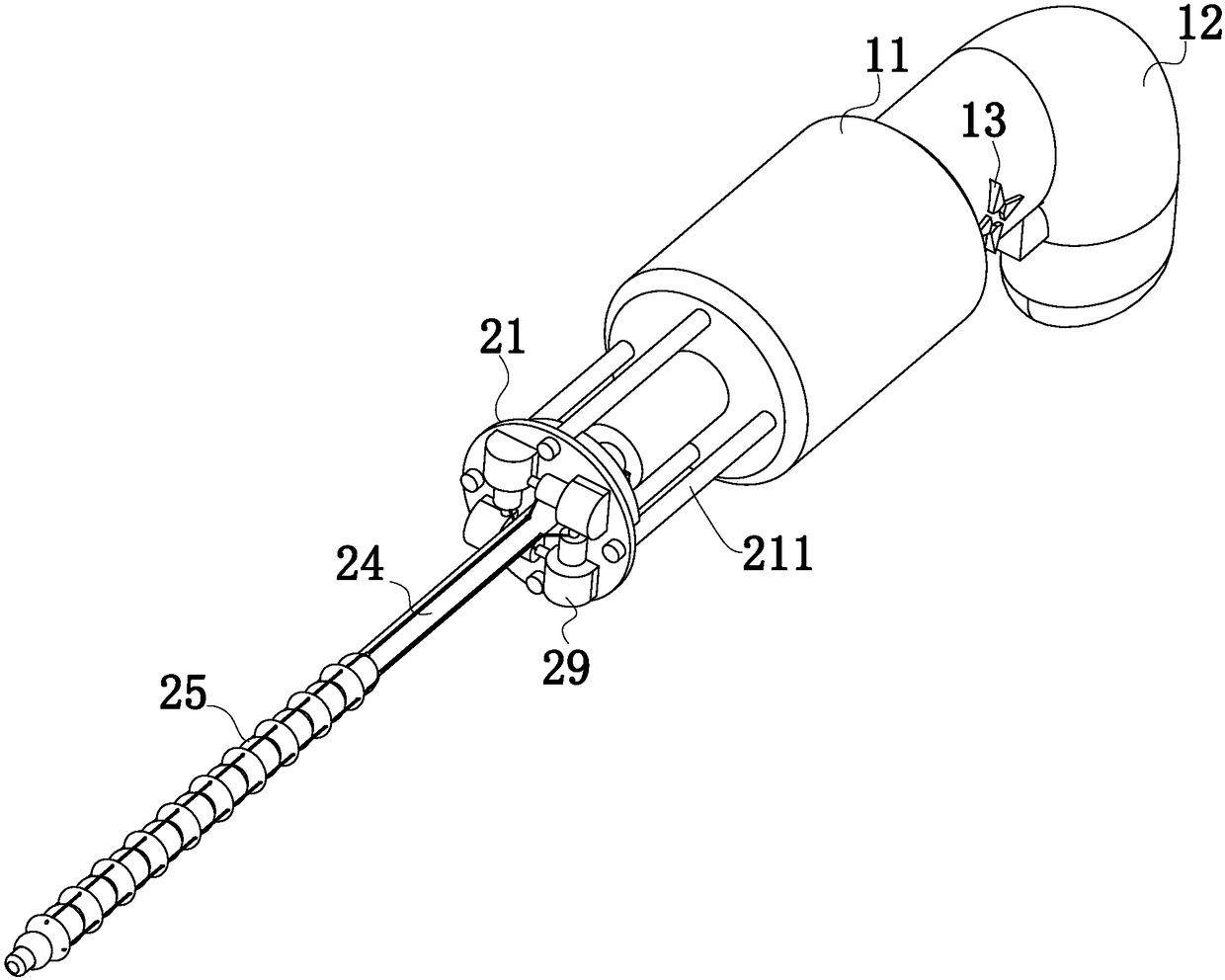

[0042] Such as figure 1 , figure 2 , Figure 9 , an engraving machine kit for punching and internal carving in this embodiment, including a handpiece 1, an engraving piece 2 and a punching piece 3; both the engraving piece 2 and the punching piece 3 are It can be installed on the handpiece 1, and only one of the engraving piece 2 and the punching piece 3 can be installed on the handpiece 1. After the punching piece 3 is installed on the handpiece 1, small holes can be punched on the jade and internal carvings can be made. After the engraving piece 2 is installed on the hand piece 1, the engraving drill bit can be inserted into the jade article for fine carving.

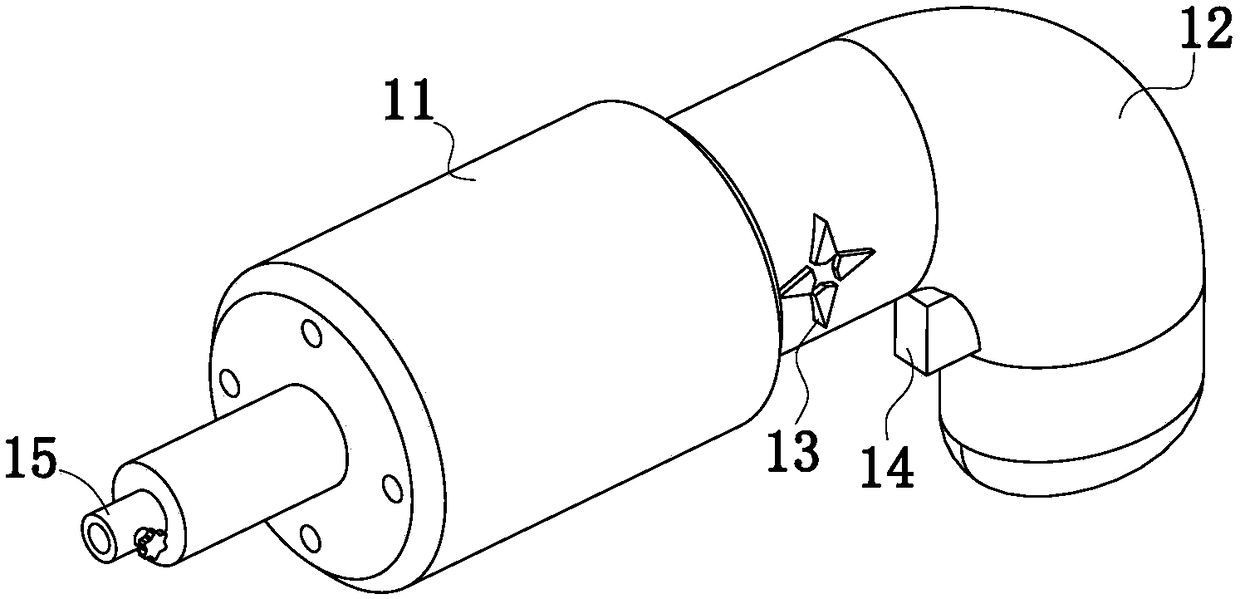

[0043] Such as image 3 , the handpiece 1 includes a main body 11, a handle 12 connected to the rear of the main body 11, a direction control button 13 arranged on the handle 12, a switch button 14 arranged on the handle 12 and a drill arranged at the front of the main body 11. chuck 15; the main body 11 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com