Ion liquid-based quasi-solid electrolyte for lithium battery and preparation method of quasi-solid electrolyte

An ionic liquid and quasi-solid-state technology, applied in the field of lithium secondary batteries, can solve problems such as low Coulombic efficiency, and achieve the effects of easy availability of raw materials, low overpotential, and long-term cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) In a glove box filled with argon gas with a purity greater than or equal to 99% and a moisture content of less than 1ppm, first place 0.91g LiN(SO 2 CF 3 ) 2 Dissolve in 4.6g N-methyl, propylpyrrolidine bistrifluoromethanesulfonimide salt, and stir for 24h to obtain ionic liquid electrolyte; then add 2.8g 3-methacryloyloxypropyl trimethoxy base silane and mix evenly; finally add 2.5mL formic acid with a purity greater than 98%, and continue stirring for 8min to obtain a reaction system;

[0033] (2) The reaction system obtained in step (1) was removed from the glove box, placed in a vacuum oven with a relative vacuum of -80KPa, and dried at 50°C for 7 days to obtain a quasi-solid electrolyte based on ionic liquid for lithium batteries.

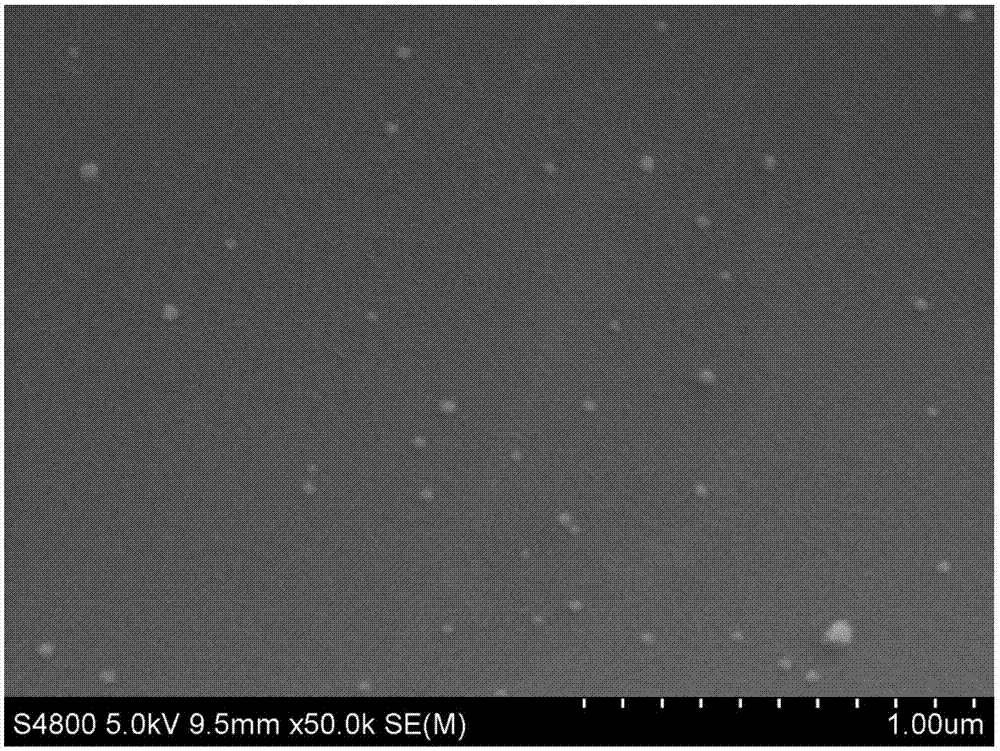

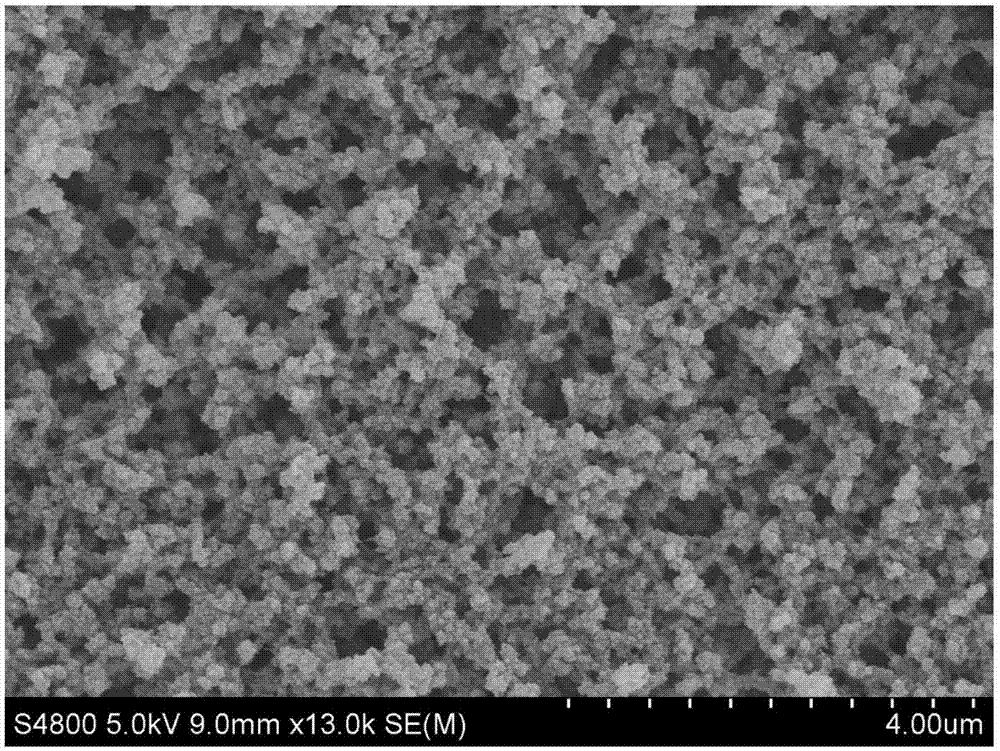

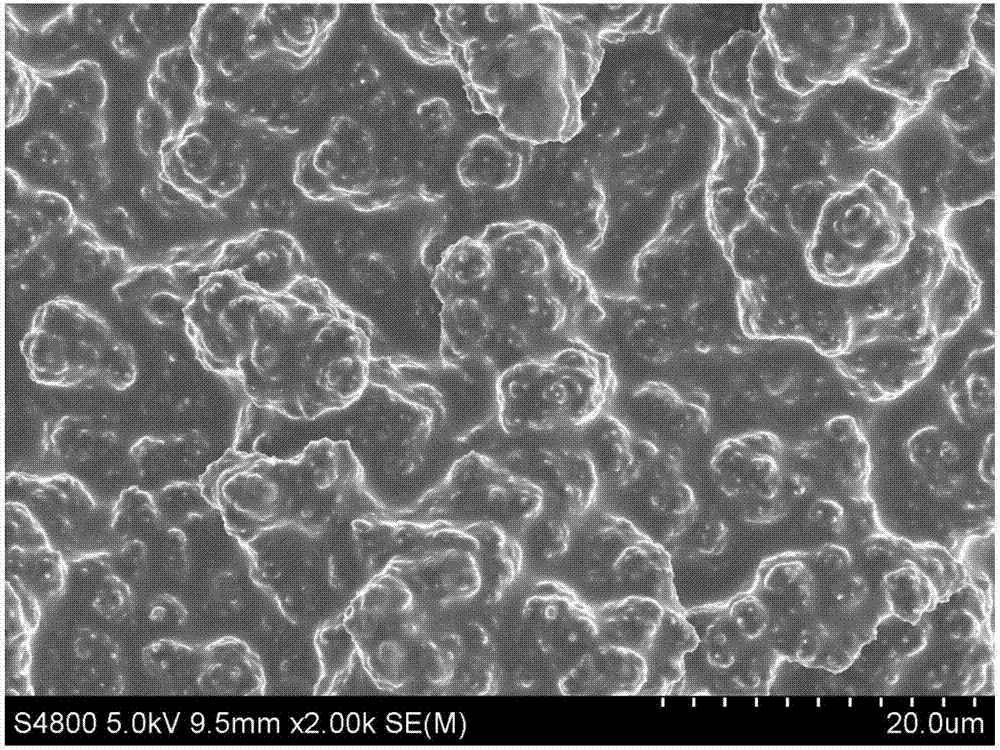

[0034] from figure 1 It can be seen from the SEM images in the figure that the surface of the quasi-solid electrolyte prepared in this embodiment is smooth without cracks. The resulting quasi-solid-state electrolyte was washed t...

Embodiment 2

[0037] (1) In a glove box filled with argon gas with a purity greater than or equal to 99% and a moisture content of less than 1ppm, first put 1.82g LiN(SO 2 CF 3 ) 2 Dissolve in 4.6g N-methyl, propylpyrrolidine bistrifluoromethanesulfonimide salt, and stir for 24h to obtain an ionic liquid electrolyte; then add 0.7g 3-methacryloyloxypropyl trimethoxy base silane and 0.82g 3-methacryloxypropyltriethoxysilane and mix well; finally add 1.25mL formic acid with a purity greater than 98%, and continue stirring for 8min to obtain a reaction system;

[0038] (2) The reaction system obtained in step (1) was removed from the glove box, placed in a vacuum drying oven with a relative vacuum of -100KPa, and dried at 70°C for 7 days to obtain a quasi-solid electrolyte based on ionic liquid for lithium batteries.

[0039] From the SEM image of the quasi-solid electrolyte prepared in this example, it can be seen that the prepared quasi-solid electrolyte has a smooth surface without cracks,...

Embodiment 3

[0042] (1) In a glove box filled with argon gas with a purity greater than or equal to 99% and a moisture content of less than 1ppm, first place 4.368g LiN(SO 2 CF 3 ) 2 Dissolve in 4.6g N-methyl, propylpyrrolidine bis-trifluoromethanesulfonimide salt and 10.1g N-methyl, propylpiperidine bis-trifluoromethanesulfonimide salt, and stir for 24h to obtain Ionic liquid electrolyte; add 1.4g 3-methacryloxypropyltrimethoxysilane, 0.82g 3-methacryloxypropyltriethoxysilane and 0.65g γ-methacryloxy Propylmethyldimethoxysilane and mix well; finally add 1.62g of high-purity water, and continue to stir for 15min to obtain a reaction system;

[0043] (2) The reaction system obtained in step (1) was removed from the glove box, placed in a vacuum oven with a relative vacuum of -90KPa, and dried at 90°C for 5 days to obtain a quasi-solid electrolyte based on ionic liquid for lithium batteries.

[0044] From the SEM image of the quasi-solid electrolyte prepared in this example, it can be see...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com