A kind of preparation method of nanometer red phosphorus and graphene composite negative electrode material

A graphene composite and negative electrode material technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of uneven particle size distribution, time-consuming and labor-intensive, high energy consumption, etc., to achieve uniform distribution , broad application prospects, large reaction surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

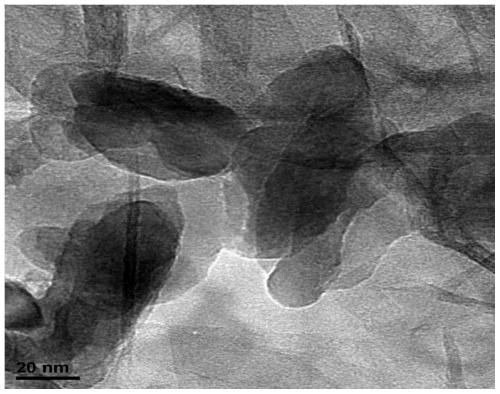

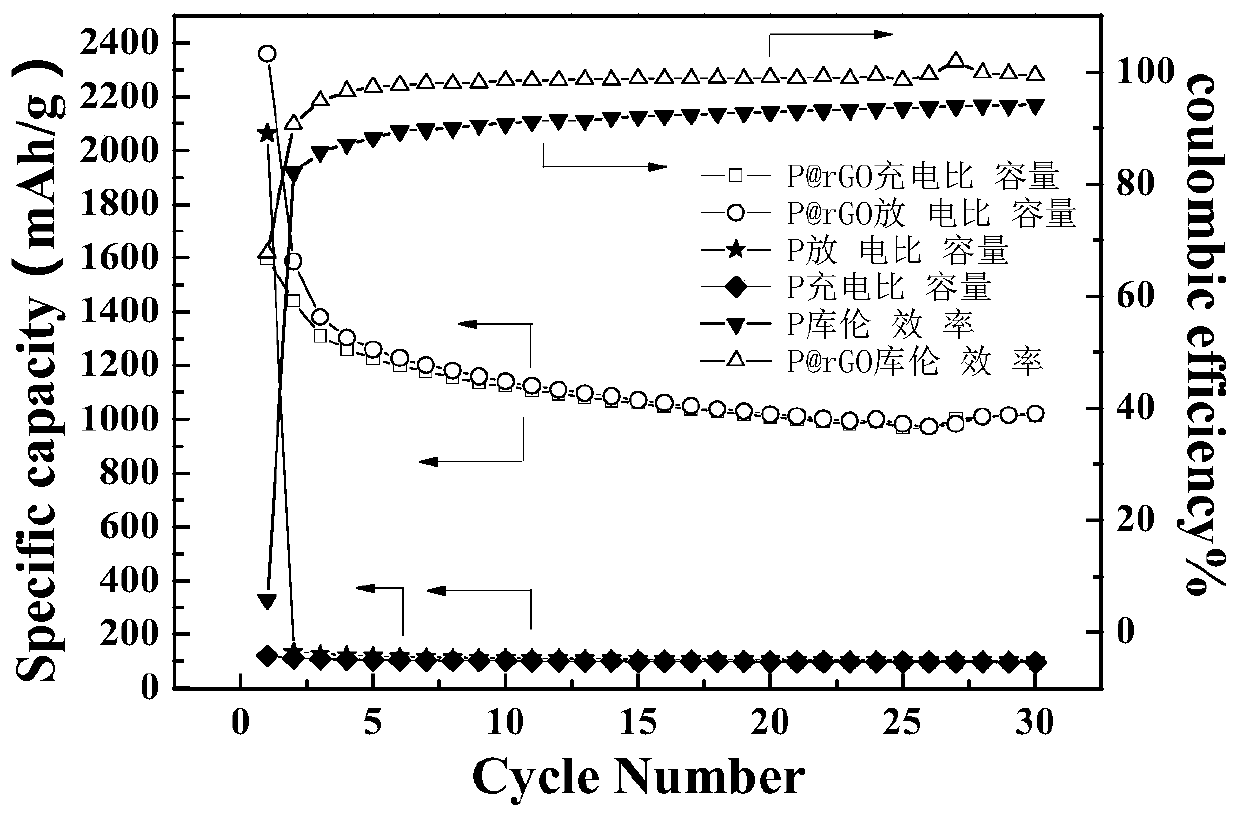

[0028] Example 1, see figure 1 with figure 2 :

[0029] The invention provides a preparation method of nano red phosphorus and graphene composite negative electrode material, comprising the following steps:

[0030] (1) Preparation of sub-micron red phosphorus: Take 0.5 g of commercial red phosphorus, add water and wet mill for 5 min, transfer to a reaction kettle filled with 60 mL of deionized water, disperse by ultrasonic treatment for 1 h, and disperse at 200 °C, Carry out solvothermal reaction at a speed of 1000r / min for 12 hours. After the reaction is completed, naturally cool to room temperature, filter with suction, and filter and wash with deionized water. The filter residue is dried in a vacuum oven at 60°C for 12 hours to obtain submicron red phosphorus;

[0031] (2) Preparation of graphene oxide: Ultrasound-assisted improved Hummers method was used to add 1.0g flake graphite to 23mL 0°C concentrated sulfuric acid under stirring conditions and slowly add 3.0g pot...

Embodiment 2

[0035] The invention provides a preparation method of nano red phosphorus and graphene composite negative electrode material, comprising the following steps:

[0036] (1) Preparation of submicron red phosphorus: take 0.7g of commercial red phosphorus, add water and wet mill for 5min, transfer to a reaction kettle filled with 60mL of absolute ethanol, disperse by ultrasonic treatment for 1h, and disperse at 180℃, Carry out solvothermal reaction at a speed of 750r / min for 24 hours. After the reaction is completed, naturally cool to room temperature, filter with suction, and filter and wash with absolute ethanol. The filter residue is dried in a vacuum oven at 60°C for 12 hours to obtain submicron red phosphorus;

[0037] (2) Preparation of graphene oxide: Ultrasound-assisted improved Hummers method was used to add 1.0g flake graphite to 23mL 0°C concentrated sulfuric acid under stirring conditions and slowly add 3.0g potassium permanganate, react at low temperature for 2h, and i...

Embodiment 3

[0040] The invention provides a preparation method of nano red phosphorus and graphene composite negative electrode material, comprising the following steps:

[0041](1) Preparation of submicron-sized red phosphorus: Take 1.0 g of commercial red phosphorus, add water and wet mill for 5 min, transfer it to a reaction kettle filled with 60 mL of anhydrous ether, and disperse it by ultrasonic treatment for 1 h. Carry out solvothermal reaction at a speed of 500r / min for 24 hours. After the reaction is completed, naturally cool to room temperature, filter with suction, and filter and wash with anhydrous ether. The filter residue is dried in a vacuum oven at 60°C for 12 hours to obtain submicron red phosphorus;

[0042] (2) Preparation of graphene oxide: Ultrasound-assisted improved Hummers method was used to add 1.0g flake graphite to 23mL 0°C concentrated sulfuric acid under stirring conditions, and slowly add 3.0g potassium permanganate, react at low temperature for 2h, medium an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com