Electronic expansion valve and valve seat assembly thereof, and machining method of valve seat assembly

A technology of electronic expansion valve and processing method, which is applied in the direction of refrigeration components, metal processing equipment, valve operation/release devices, etc., and can solve the problems of long solder penetration path, pressure bias falling off, and reduced welding strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

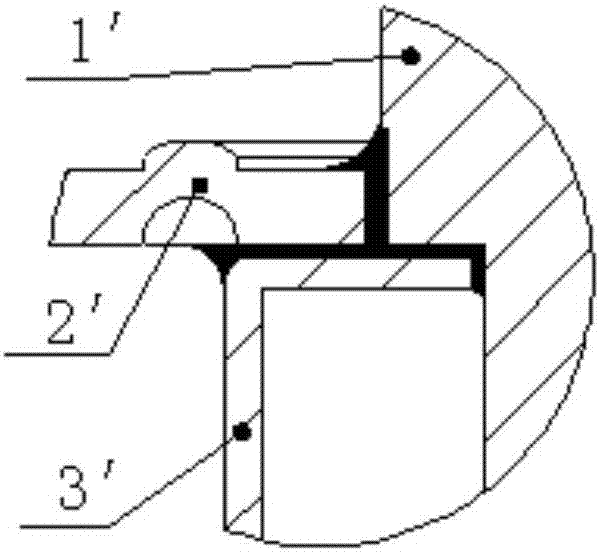

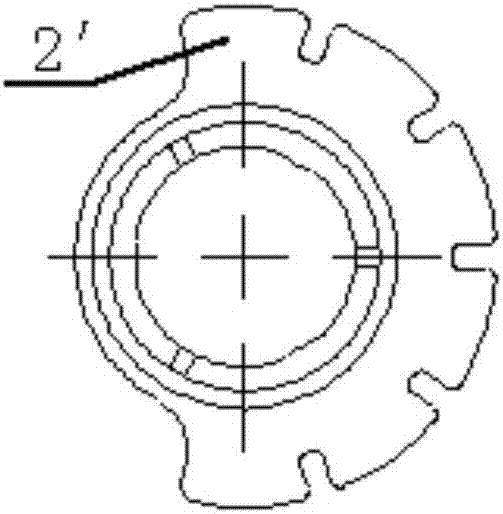

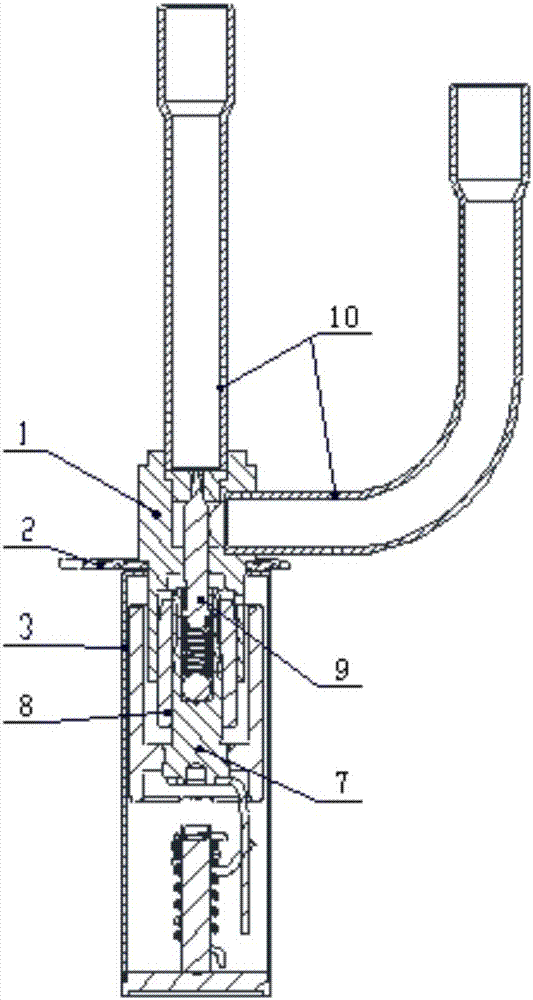

[0046] The invention provides an electronic expansion valve, its valve seat assembly, and a processing method for the valve seat assembly, which can improve welding strength, effectively reduce welding defects such as lack of welding, air holes, and welding leakage during the welding process, and enhance welding quality.

[0047] The electronic expansion valve, its valve seat assembly, and the processing method of the valve seat assembly of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can accurately understand the technical solution of the present invention.

[0048] The orientation described in this paper refers to the electronic expansion valve, and the extension direction of the valve seat 1 and the casing 3 is the axial direction; taking the central axis of the casing 3 as the reference, the direction close to the central axis of the casing 3 is the inner direction, and the direction a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com