Rapid construction vibration device based on municipal road project

A municipal road and engineering technology, which is applied in the field of rapid construction leveling devices, can solve the problems of high maintenance costs, hollow ground, shelling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

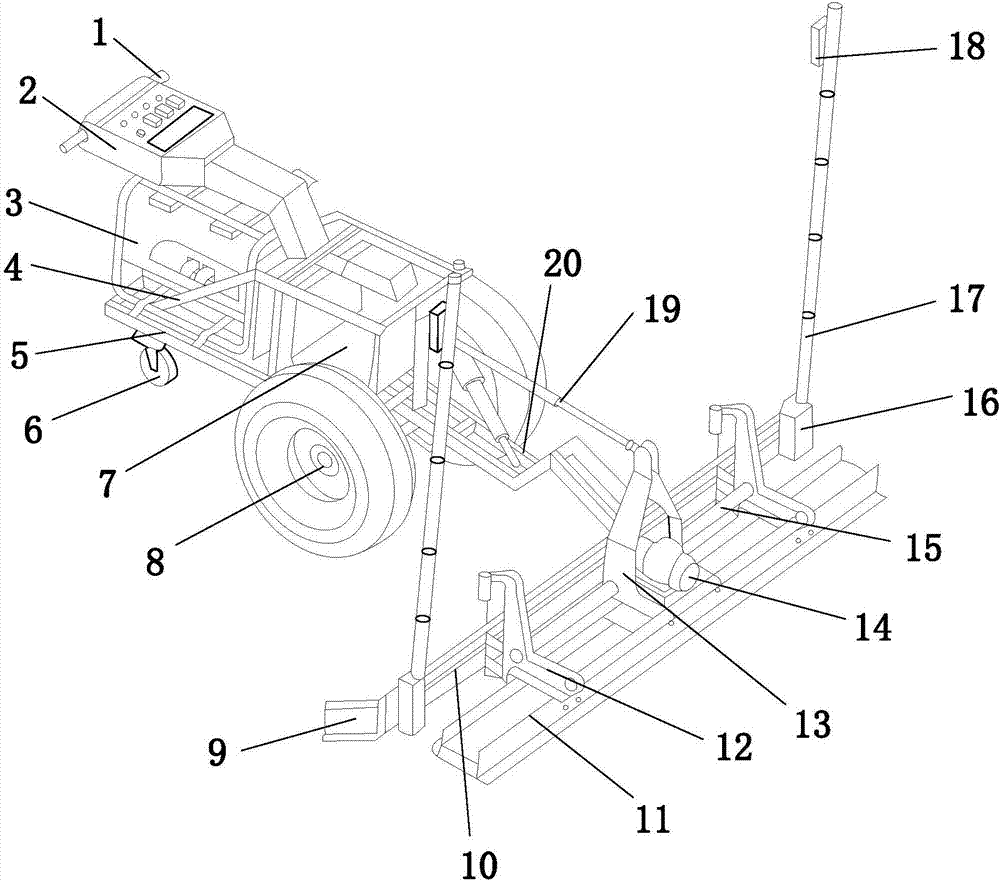

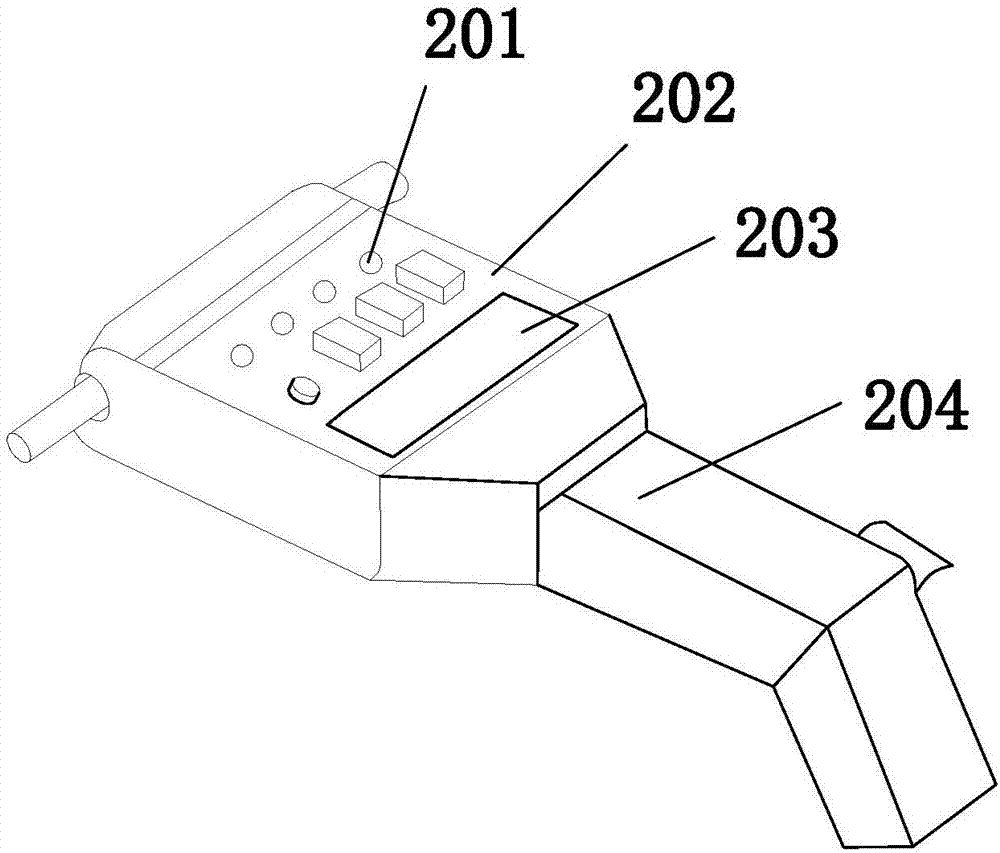

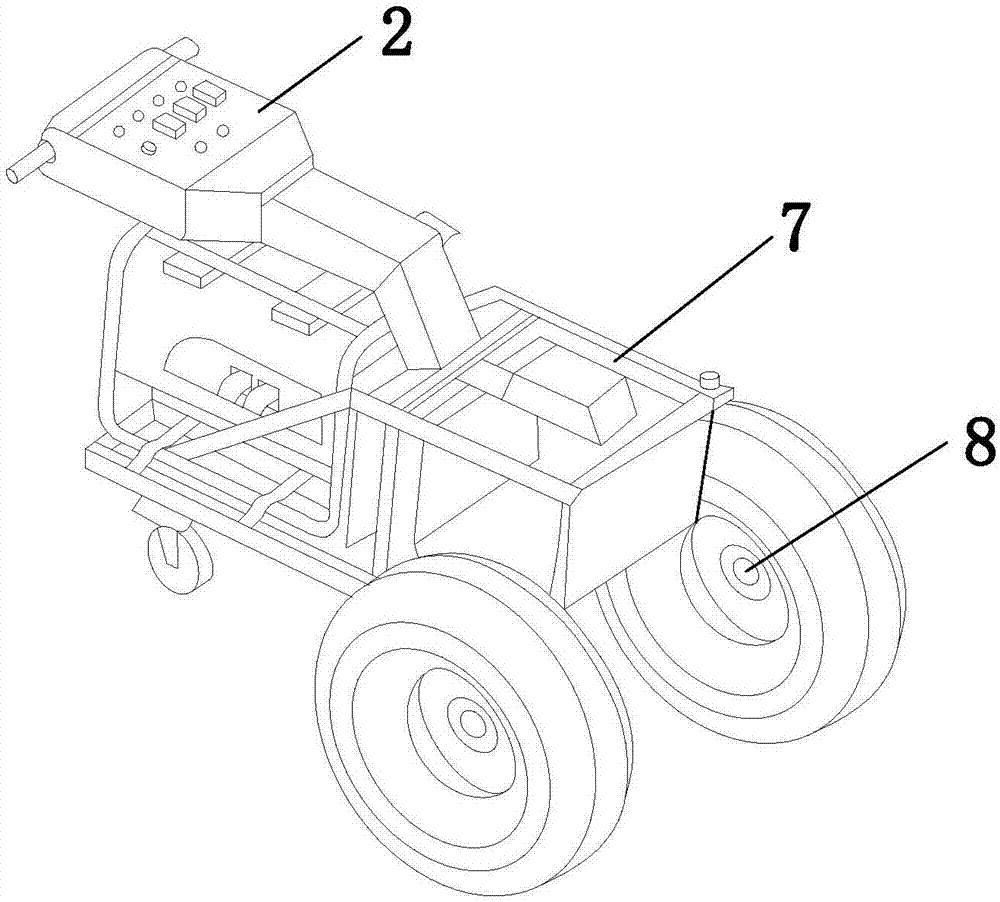

[0034] see Figure 1-Figure 9, the present invention provides a rapid construction leveling device based on municipal road engineering, its structure includes a handle 1, an operator 2, a motor 3, a guardrail 4, a support plate 5, auxiliary wheels 6, a control system 7, and a driving wheel 8 , side plate 9, scraper plate 10, vibrating plate 11, vibrating head 12, fixed protective end 13, vibrating motor 14, limit rod 15, fixed base 16, support column 17, laser receiver 18, hydraulic rod 19, movable Connecting plate 20, laser emission port 21, laser emitter 22, first fixed disk 23, disk fixed rod 24, second fixed disk 25, connecting ring plate 26, buckle 27, support foot 28, bolt 29, The bottom foot 30, the driving wheel 8 is provided with two and is installed on the support plate 5 close to the control system 7 through the connecting shaft, and the motor 3 and the control system 7 are both fixedly installed on the support plate 5 and mechanically connected , one end of the su...

Embodiment 2

[0037] see Figure 1-Figure 10 , the support column 17 includes a reinforcement core 171, a bracket 172, a polyethylene filling layer 173, a reinforcement ring 174, a pipe body 175, and a connecting column 176, and the reinforcement core 171 is installed inside the pipe body 175, and the support 172 Both ends are internally connected to the inside of the pipe body 175, the polyethylene filling layer 173 is filled on the inner wall of the pipe body 175 as an integral structure, and the reinforcing ring 174 is evenly sleeved on the pipe body 175 and is tightly connected to the outer wall of the pipe body 175. touch.

[0038] In order to save the design cost of the present invention, the support column 17 is designed as a pipe body with an internal hollow structure, and the inner wall of the pipe body 175 is filled with a polyethylene filling layer 173. Due to the extremely low low-temperature embrittlement temperature of polyethylene, it can be used in - It is safe to use in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com