Aqueous toughened glass printing ink dedicated for touch screen and preparation method thereof

A tempered glass ink and touch screen technology, applied in ink, applications, home appliances, etc., can solve problems such as signal attenuation, and achieve the effect of compact structure, good chemical stability, and low expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

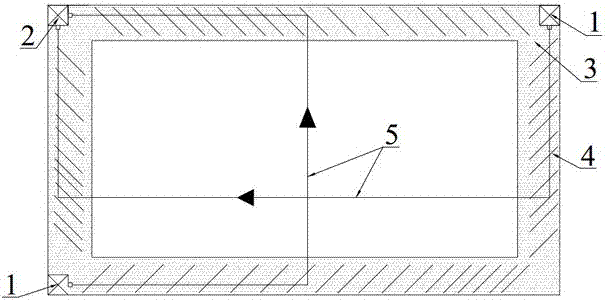

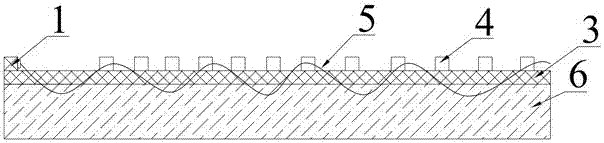

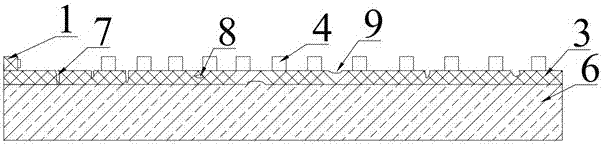

Image

Examples

Embodiment 1

[0031] A special water-based tempered glass ink for a touch screen, made of the following raw materials in parts by weight: 12 parts of inorganic pigments, 40 parts of the first glass frit, 10 parts of the second glass frit, 37 parts of water-based varnish, Wetting and dispersing agent 0.5 part, defoamer 0.5 part.

[0032] The first glass powder frit is made up of the composition of following percentage by weight: SiO 2 30%, B 2 o 3 6.8%, Al 2 o 3 2%, Na 2 O 4.5%, K 2 O 2.5%, CaO 3.8%, Li 2 O 6%, TiO 2 3.8%, F 1.5%, Sb 2 o 3 0.5%, the balance is ZnO.

[0033] The second glass powder frit is made up of the composition of following percentage by weight: SiO 2 12%, B 2 o 3 13%, Al 2 o 3 1.5% balance is Bi 2 o 3 .

[0034] The water-based varnish is made up of the following components by weight percentage: 25% water-based modified acrylic polymer HOMAAC TM 5224D (Jintuan Chemicals), 1% water-based hydroxyethyl cellulose HBR250 (Ashlane), 14.6% ethanol, ...

Embodiment 2

[0044] A special water-based tempered glass ink for a touch screen, made of the following raw materials in parts by weight: 12 parts of inorganic pigments, 32 parts of first glass powder frit, 16 parts of second glass frit, 38.2 parts of water-based varnish, 0.5 parts of wetting and dispersing agent, 0.5 parts of defoaming agent, and 0.8 parts of leveling agent.

[0045] The first glass powder frit is made up of the composition of following percentage by weight: SiO 2 35%, B 2 o 3 12%, Al 2 o 3 1.5%, Na 2 O 8.2%, K 2 O 0.3%, CaO 3.8%, BaO 3.7%, Li 2 O 12%, TiO 2 0.5%, F 1.8%, and the balance is ZnO.

[0046] The second glass powder frit is made up of the composition of following percentage by weight: SiO 2 6%, B 2 o 3 14%, Al 2 o 3 1.5% balance is Bi 2 o 3 .

[0047] The water-based varnish is made up of the following components by weight percentage: 32% water-based modified acrylic polymer HOMAAC TM 5224D (Jintuan Chemicals), 1.5% water-based hydroxye...

Embodiment 3

[0057] A special water-based tempered glass ink for a touch screen, made of the following raw materials in parts by weight: 12 parts of inorganic pigments, 38 parts of the first glass frit, 12 parts of the second glass frit, 37 parts of water-based varnish, Wetting and dispersing agent 0.5 part, defoamer 0.5 part.

[0058] The first glass powder frit is made up of the composition of following percentage by weight: SiO 2 28.2%, B 2 o 3 8.2%, Al 2 o 3 4%, Na 2 O 6.5%, K 2 O 2.1%, CaO 0.8%, BaO 7.2%, Li 2 O 9%, TiO 2 1.2%, F 3%, and the balance is ZnO.

[0059] The second glass powder frit is made up of the composition of following percentage by weight: SiO 2 12%, B 2 o 3 13%, Al 2 o 3 1.5% balance is Bi 2 o 3 .

[0060] The water-based varnish is composed of the following components by weight percentage: 35% water-based modified acrylic polymer HOMAAC TM 5224D (Jintuan Chemicals), 0.8% water-based hydroxyethyl cellulose HBR250 (Ashlan), 15% ethanol, 10% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com