Spray-coating-free scratch-resistant PP alloy material and preparation method thereof

An alloy material and scratch-resistant technology, which is applied in the field of composite materials, can solve the problem of unknown spray-free effect, etc., and achieve the effects of excellent scratch resistance, slowing flow marks and reducing flow difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

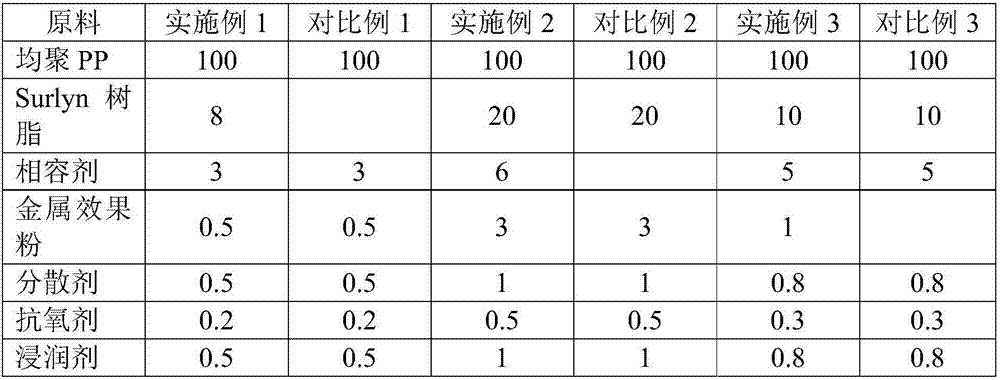

Embodiment 1~3

[0028] The present examples 1-3 relate to the spray-free scratch-resistant PP alloy material composition, and the components contained therein and their dosage are shown in Table 1. Among them, PP is homopolymerized PP with a melting index of 20g / 10min; the transparent ionic polymer is Surlyn8150; the compatibilizer is PP-g-MAH; the metal powder pigment is aluminum silver powder with a particle size of 20μm; the dispersant is polyester grafted Modified silicone and polyethylene wax are compounded at a weight ratio of 2:1; the wetting agent is white oil; the antioxidant is a compound of hindered phenolic antioxidant and phosphite antioxidant.

[0029] When preparing, weigh each raw material according to the weight percentage in Table 1, and add PP, compatibilizer, transparent ionomer and sizing agent into the high mixer, and mix at a speed of 300-400rpm for 3-5min, Add metal powder pigment, dispersant and antioxidant, and then mix at a speed of 100-200rpm for 2-3min to form a p...

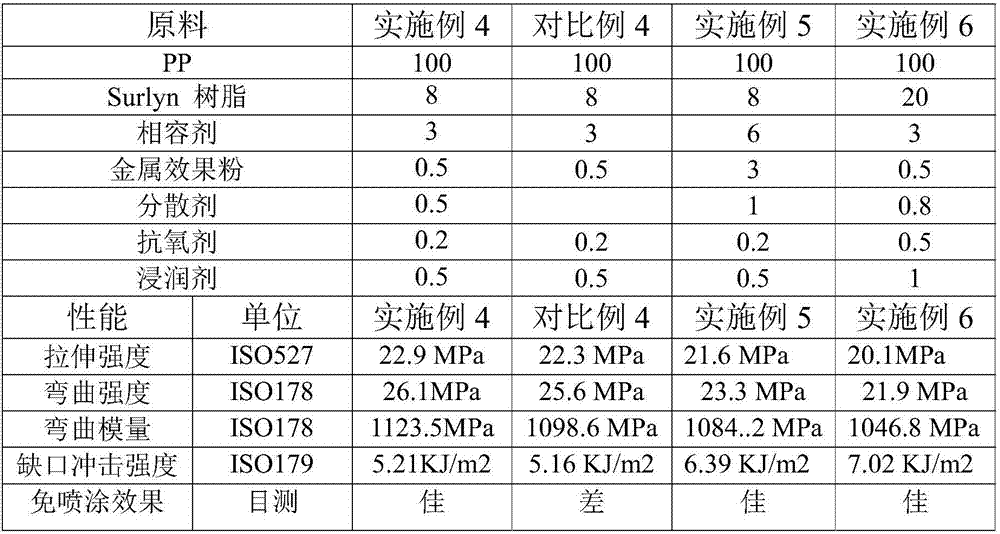

Embodiment 4~6

[0039] Examples 4 to 6 relate to the spray-free scratch-resistant PP alloy material composition, and the components and their dosage are shown in Table 3. Among them, PP is homopolymerized PP with a melting index of 40g / 10min; the transparent ionic polymer is Surlyn8150; the compatibilizer is PE-g-MAH; the metal powder pigment is aluminum silver powder with a particle size of 70 μm; the dispersant is polyester grafted Modified silicone and polyethylene wax are compounded at a weight ratio of 2:1; the wetting agent is white oil; the antioxidant is a compound of hindered phenolic antioxidant and phosphite antioxidant. The concrete selection of each component is with embodiment 1.

[0040] When preparing, weigh each raw material according to the weight percentage in Table 1, and add PP, compatibilizer, transparent ionomer and sizing agent into the high mixer, and mix at a speed of 300-400rpm for 3-5min, Add metal powder pigment, dispersant and antioxidant, and then mix at a spee...

Embodiment 7

[0046]A spray-free scratch-resistant PP alloy material is prepared by using the following components and raw materials in parts by weight:

[0047] Polypropylene 100, transparent ionic polymer 5, compatibilizer 3, metal powder pigment 0.5, dispersant 0.5, sizing agent 0.5, antioxidant 0.2;

[0048] Among them, the dispersant used is compounded by polyester grafted modified silicone and polyethylene wax in a weight ratio of 2:1, and the grafting rate of polyester grafted modified silicone is 0.8%. Since the dispersant contains polyester grafted modified silicone, which has a certain reactivity, it can improve the compatibility between metal pigments and PP resin, reduce the flow difference between PP resin and metal effect powder, and slow down the flow marks. Purpose. The purpose of compounding polyethylene wax and polyester graft modified silicone is that polyethylene wax has processing lubrication effect, and can also improve the dispersion of polyester graft modified silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com