Lightening method of battery protective cover for electric buses and battery protective cover

An electric passenger car and protective cover technology, which is applied to secondary batteries, electric power devices, electrochemical generators, etc. The general rust effect and other problems can improve the overall appearance effect, reduce the weight and production cost, and meet the needs of lightweight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

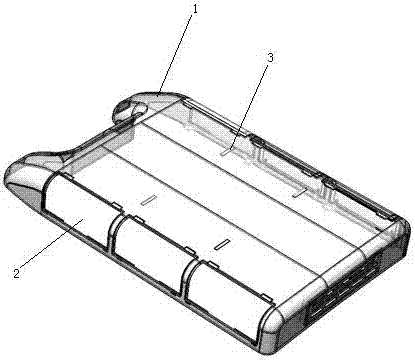

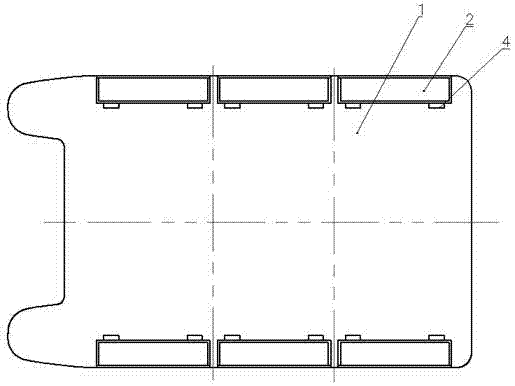

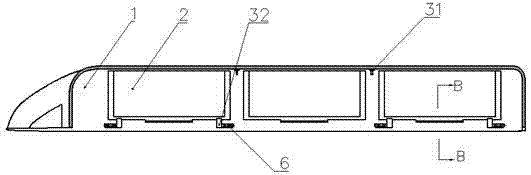

[0034] Combine below Figure 1 to Figure 5 Embodiments of the present invention are described in detail.

[0035] A lightweight method for the battery protective cover of an electric bus, the battery protective cover includes a protective cover main body 1, an inspection door 2 mounted on the protective cover main body 1, and a connector 3 for installation and connection of the battery protective cover, which is characterized in that the The materials of the main body 1 of the protective cover and the access door 2 are heat-insulating sandwich materials. The heat-insulating sandwich material is composed of two layers of glass fiber reinforced plastic layers A and a PVC foam layer B bonded between the two layers of glass fiber reinforced plastic layers A. The above-mentioned connector 3 is pre-embedded in the main body 1 of the protective cover.

[0036] The protective cover body 1 and the access door in the battery protective cover are all made of heat-insulating sandwich mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com