Dynamically variable potential energy type laminar flow cooling device

A laminar cooling device, potential energy technology, applied in workpiece cooling device, workpiece surface treatment equipment, metal rolling, etc., can solve the problems of poor cooling effect, turbulent cooling water, long cooling line length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

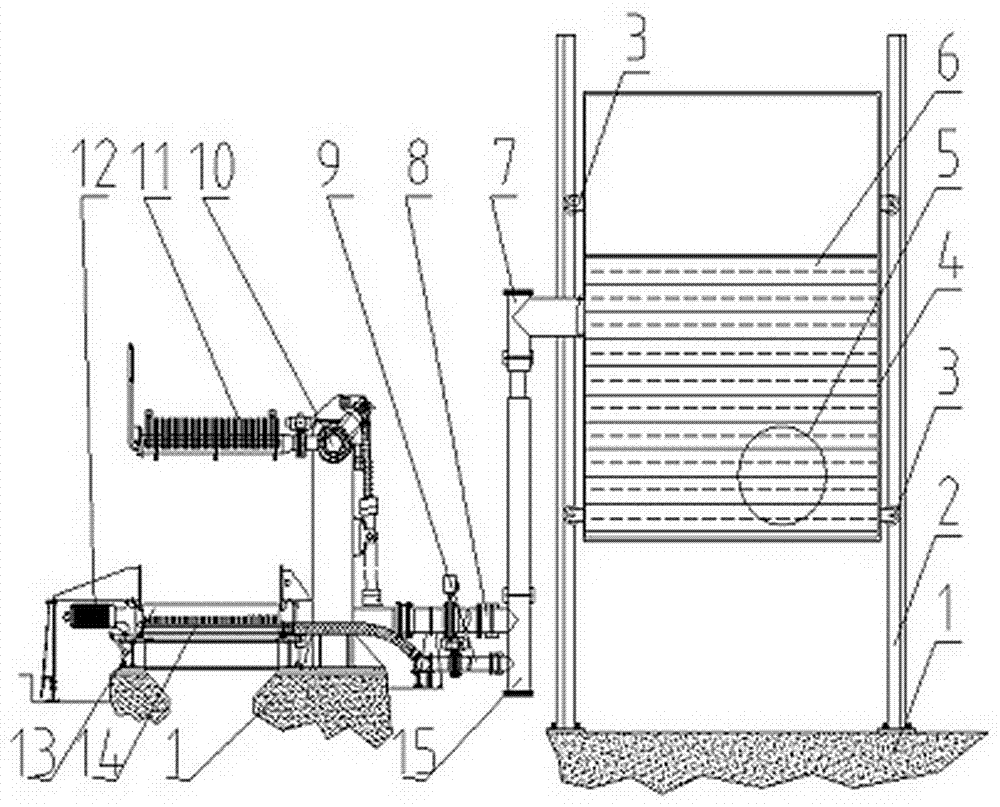

[0010] as attached figure 1 As shown, a dynamic potential energy type laminar flow cooling device mainly includes a foundation 1, a slideway 2, a pulley 3, a water tank 4, a water inlet pipe 5, cooling water 6, a telescopic outlet pipe 7, an upper branch pipe 8, and a lower branch pipe 9 , rotating pipe 10, upper header 11, roller table 13, lower header 14, fixed outlet pipe 15. Water tank 4 is housed between 2 slideways that double as frame, and pulley 3, water inlet pipe 5, flexible water outlet pipe 7 are housed on water tank 4, and cooling water 6 is housed in it. Water tank 4 can realize lifting up and down along slideway 2 by pulley 3. The telescopic water outlet pipe 7 and the fixed water outlet pipe 15 are connected through a sleeve type telescopic seal. The fixed water outlet pipe 15 is through-connected with the upper header 11 and the lower header 14 through the upper branch pipe 8 and the lower branch pipe 9 respectively. Slideway 2, roller table 13, upper heade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com