Connecting structure of gas stove burner and spraying nozzle

A connection structure and gas stove technology, applied in the field of gas stoves, can solve the problems that gas cannot enter straightly, reduce the combustion performance of gas stoves, and affect the intake air of the burner, so as to facilitate manufacturing, improve combustion performance, and ensure normal air intake Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

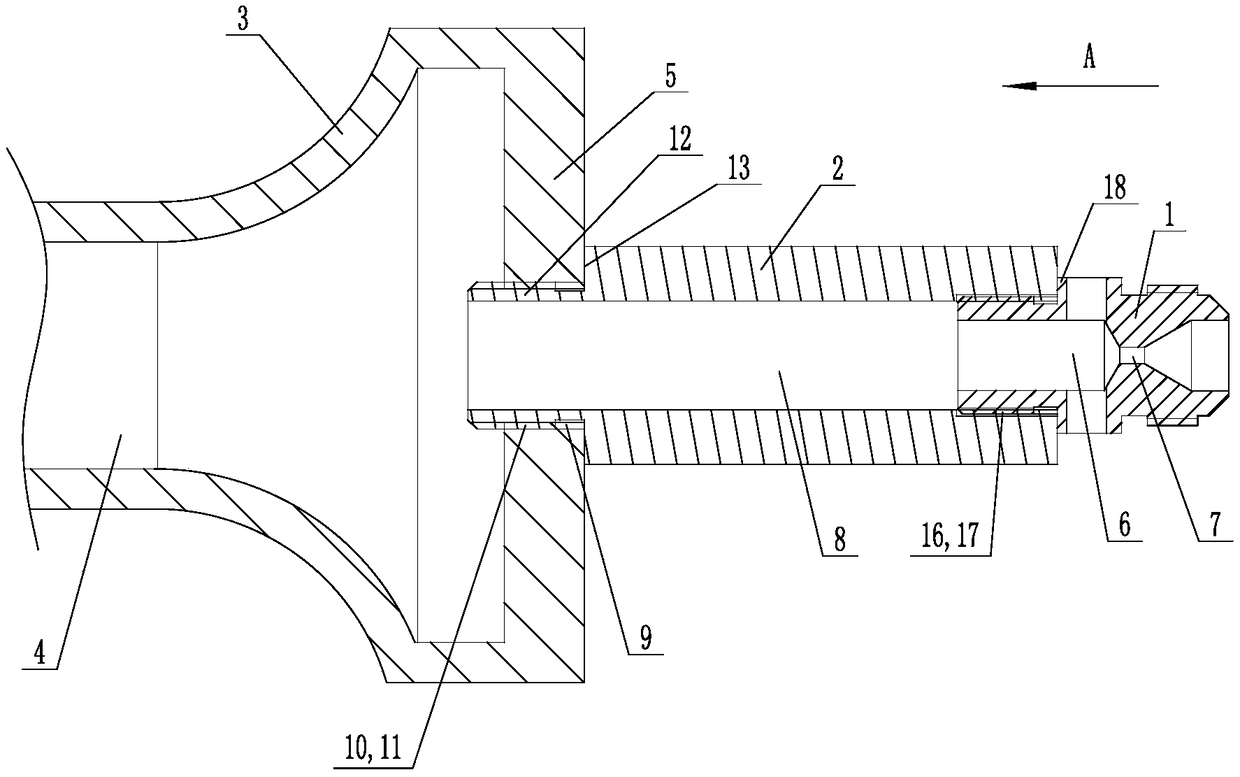

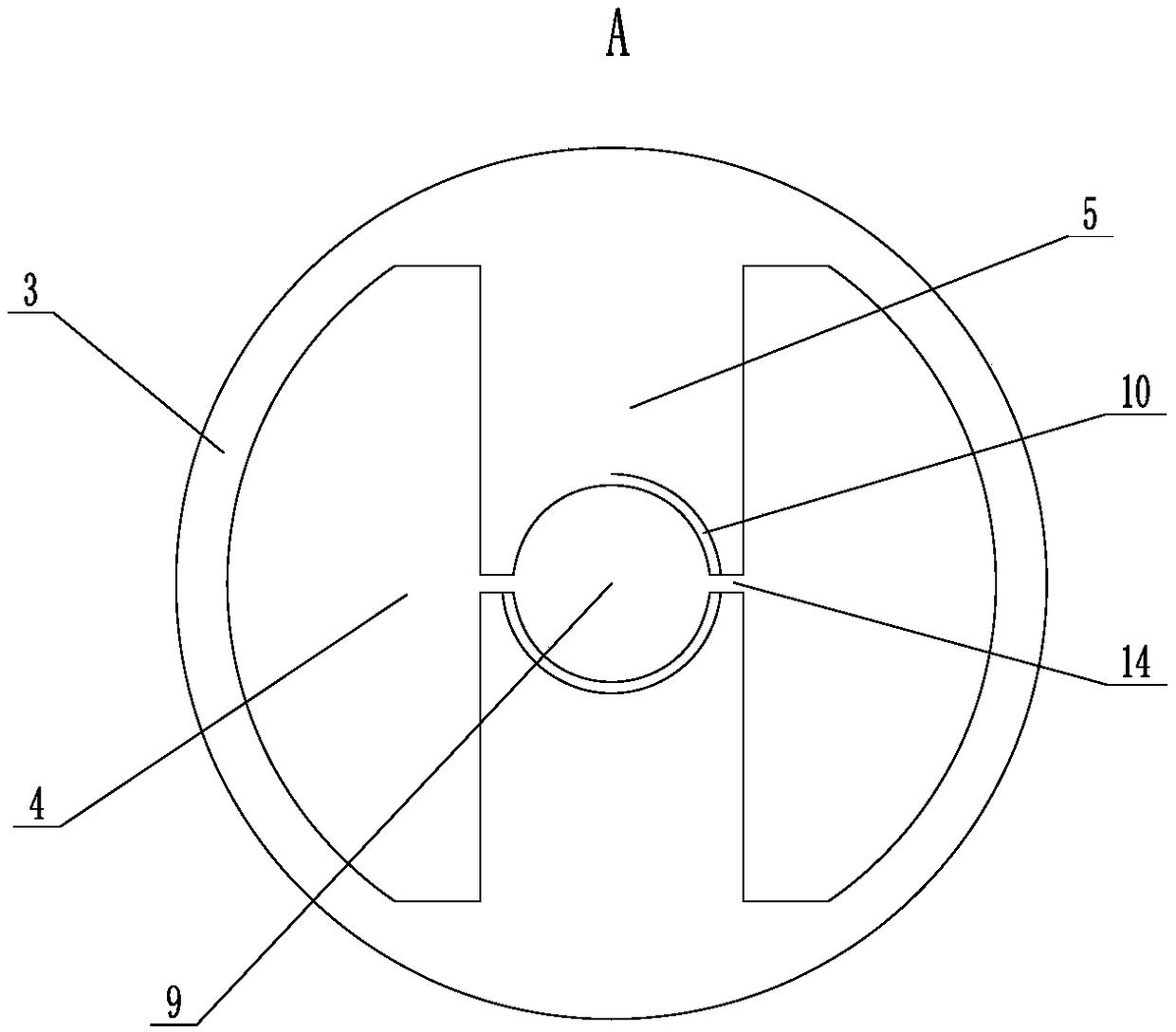

[0051] The difference between this embodiment and Embodiment 1 is that the connection structure between the guide tube 2 and the fixed plate 5 is different, such as Figure 4 and Figure 5 As shown, in this embodiment, the dividing gap 14 and the fixing hole 9 are not provided on the fixing plate 5, and the guide tube 2 and the fixing plate 5 are integrated, that is, the guide tube 2 and the fixing plate 5 are integrally formed. This structure makes the guide tube 2 No separate manufacturing is required, and there is no need to use other structures for connection and fixing between the guide pipe 2 and the fixing plate 5, which greatly facilitates the manufacture and assembly of the gas stove. At this time, there is no need to open a fixing hole 9 on the fixing plate 5 , but the guide through hole 8 needs to extend to the fixing plate 5 and pass through it.

[0052] Since the guide tube 2 and the fixed plate 5 are integrated, there is no need to set the limit step 13 and the ...

Embodiment 3

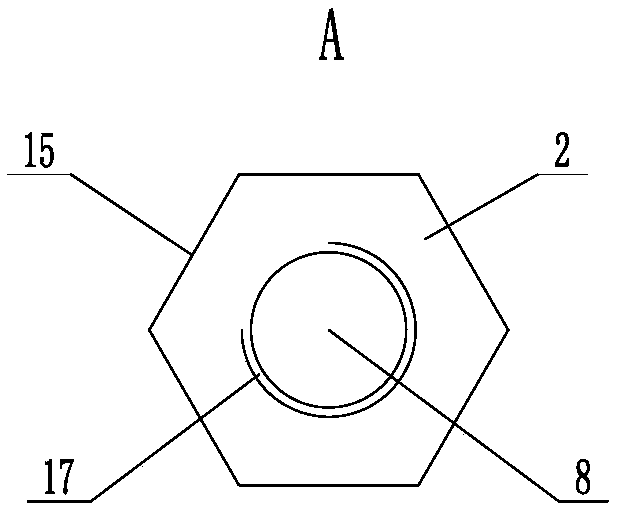

[0054] The difference between this embodiment and embodiment 1 is that the connection structure between the guide pipe 2 and the nozzle 1 is different, such as Figure 6 As shown, in the present embodiment, one end of the nozzle 1 stretches into the guide tube 2 from the air inlet of the guide through hole 8, and cooperates with the inner wall clearance of the guide through hole 8, that is, the end of the nozzle 1 air outlet. The outer peripheral wall is smooth and cylindrical, and the second external thread 16 is no longer provided, so that after one end of the air outlet of the nozzle 1 is inserted into the guide tube 2, the outer peripheral wall is adjacent to or close to the inner wall of the guide through hole 8 .

[0055] Further, the outer peripheral wall of the middle part of the nozzle 1 can be provided with a limiting boss 18, and one end of the limiting boss 18 is pressed against one end of the guide pipe 2. In this embodiment, the limiting boss 18 is directed towar...

Embodiment 4

[0058] The difference between this embodiment and embodiment 2 is that the connection structure between the guide pipe 2 and the nozzle 1 is different, such as Figure 6 As shown, in the present embodiment, one end of the nozzle 1 stretches into the guide tube 2 from the air inlet of the guide through hole 8, and cooperates with the inner wall clearance of the guide through hole 8, that is, the end of the nozzle 1 air outlet. The outer peripheral wall is smooth and cylindrical, and the second external thread 16 is no longer provided, so that after one end of the air outlet of the nozzle 1 is inserted into the guide tube 2, the outer peripheral wall is adjacent to or close to the inner wall of the guide through hole 8 .

[0059] Further, the outer peripheral wall of the middle part of the nozzle 1 can be provided with a limiting boss 18, and one end of the limiting boss 18 is pressed against one end of the guide pipe 2. In this embodiment, the limiting boss 18 is directed towar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com