Mechanical-drum turn-up tire building mechanism

A molding mechanism, drum-type technology, applied to tires, other household appliances, household appliances, etc., can solve the problems of poor stability and reliability, reduced molding quality, and short guiding distance of sector blocks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

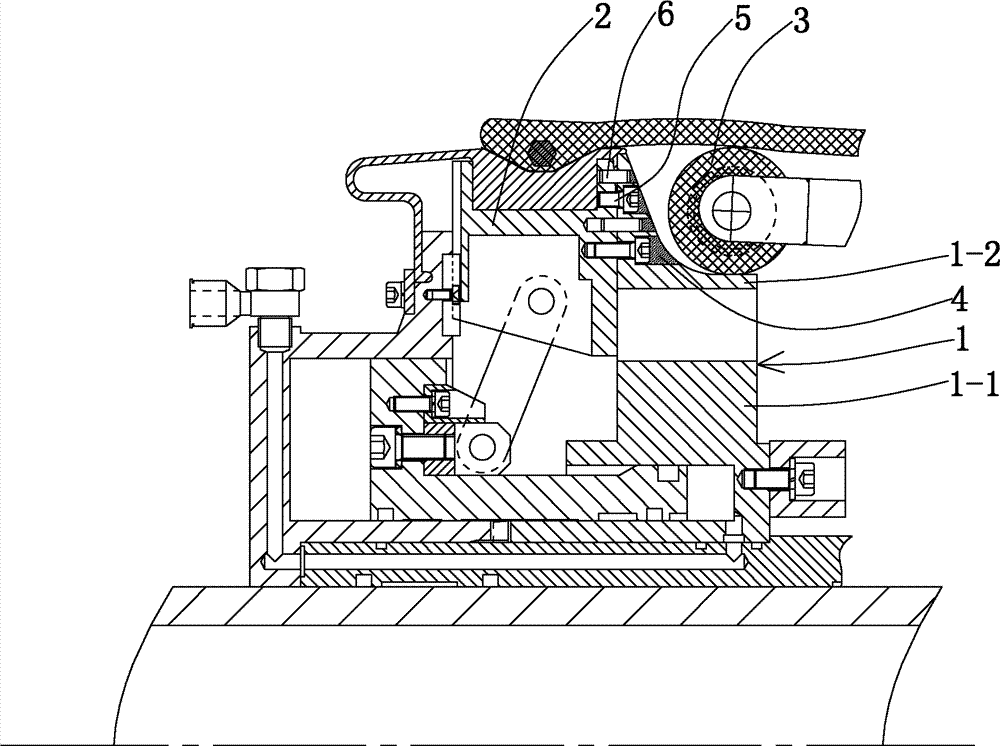

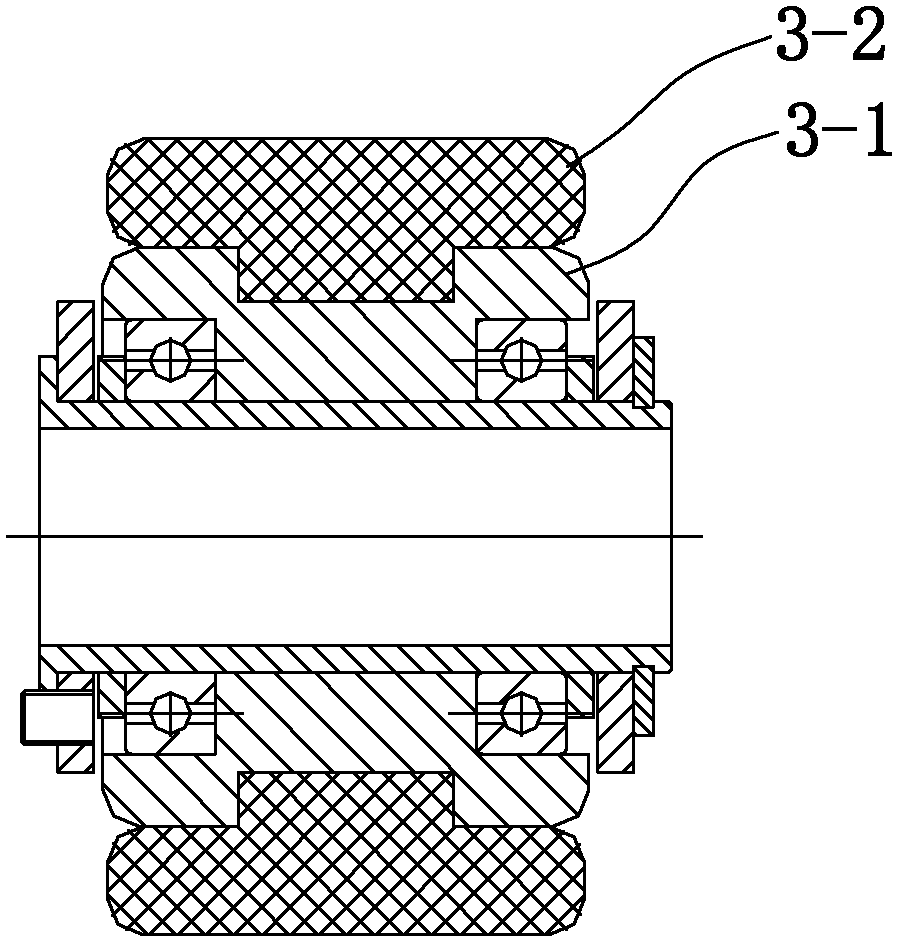

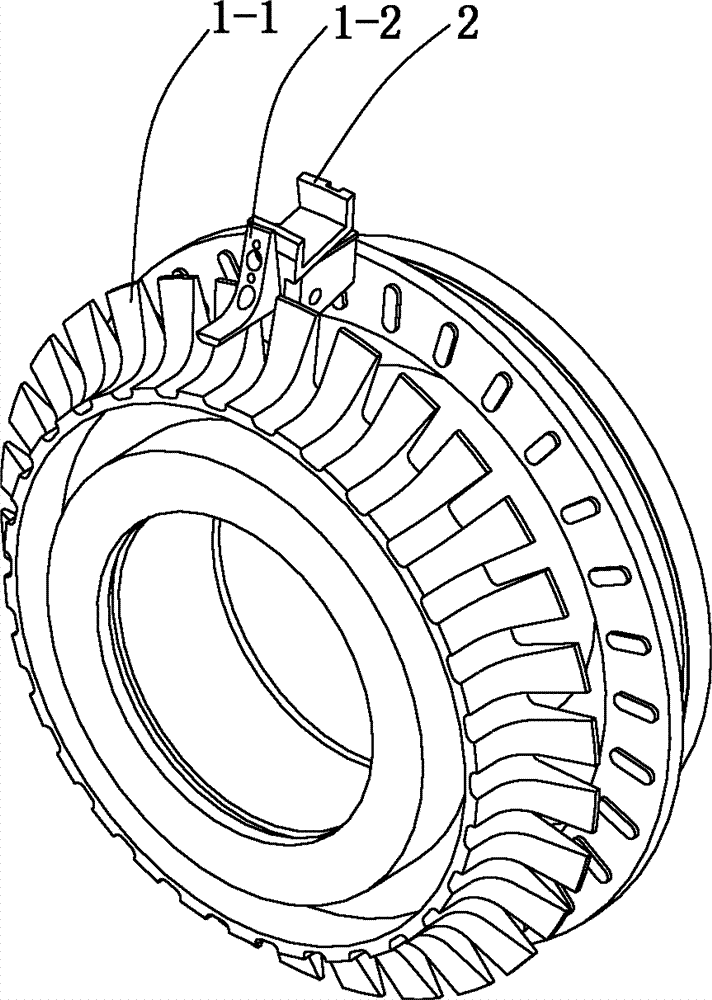

[0017] see Figure 1-3 , a mechanical drum type tire turn-up molding mechanism, including a guide plate 1 installed on the shaft sleeve opposite to the cylinder block, a sector block 2 arranged between the cylinder block and the guide plate, and a support on the arc surface of the guide plate The turn-up roller 3, the guide disc is composed of a guide disc base body 1-1 and a guide disc separation body 1-2 which is evenly distributed along the circumference and embedded on the guide disc base body, and the guide disc separation body is passed through a fastener It is fixed on the side of the fan-shaped block. Specifically, during processing, the guide plate is processed first, and then the fastener mounting hole is processed along the circumf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com