Non deep-fried instant noodles and preparation method thereof

A technology for non-fried instant noodles and noodles, applied in food science and other directions, can solve the problems of inability to achieve natural and fresh flavor, inability to retain nutrients well, and the speed of water absorption of noodles is reduced, so as to retain nutrients and save time. material, fast rehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

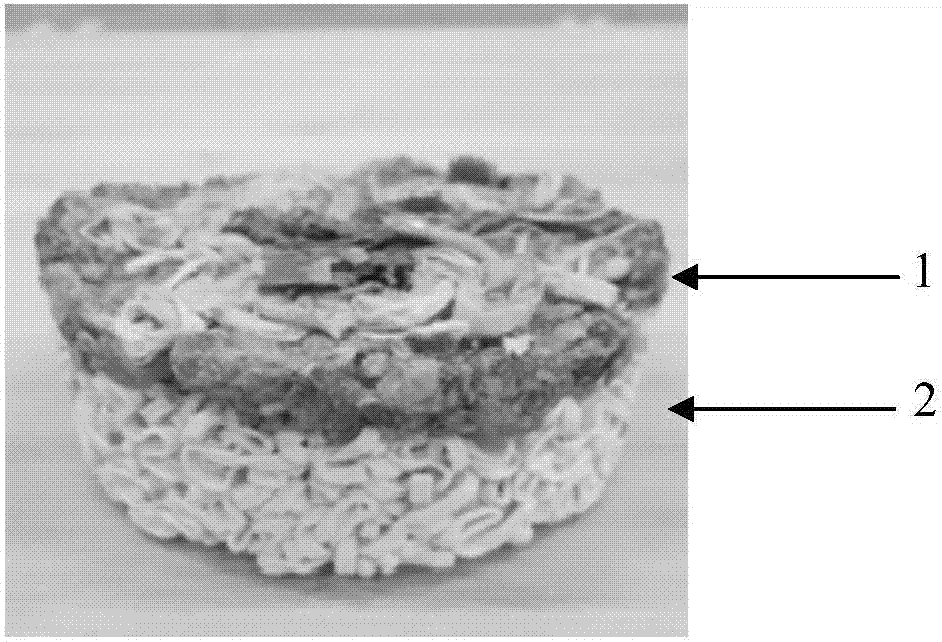

[0077] A kind of non-fried instant noodles, its structure is as figure 1 As shown, it has an integrated layered structure, the upper layer is seasoning block 1, and the lower layer is noodle cake 2; the seasoning block on the upper layer is made of fried tomato eggs with a thickness of 1 cm, and the lower layer is non-fried instant noodle cake with a thickness of 1 cm. 3cm.

[0078] The preparation method of the non-fried instant noodles of the present embodiment, carries out according to the following steps:

[0079] (1) Weigh 80g of wheat flour, 20g of modified potato starch, 5g of gluten powder, 2g of edible salt, 0.3g of sodium pyrophosphate, 0.02g of guar gum, and 0.1g of gardenia yellow pigment, and mix these raw materials with 35mL of water , kneading the dough for 12 minutes, and rolling to obtain a noodle sheet with a thickness of 1.1 mm, shred the noodle sheet, cook it under a pressure of 0.2 MPa for 3 min, and cut it into noodles with a width of 2 mm for later use;...

Embodiment 2

[0085] An instant noodle with an integrated layered structure, wherein the seasoning block on the upper layer is fried fish-flavored shredded pork layer with a thickness of 1.2 cm, and the lower layer is non-fried instant noodle cake with a thickness of 3.5 cm.

[0086] The preparation method of the instant noodles of the present embodiment, carries out according to the following steps:

[0087] (1) Noodle raw materials have the following components by weight: 75 parts of wheat flour, 30 parts of tapioca starch, 2.5 parts of gluten, 35 parts of water, 2.25 parts of salt, 0.3 part of sodium tripolyphosphate, 0.02 part of CMC xanthan gum part, capsanthin 0.1 part; kneading time 12min, noodle thickness 1.0mm, width 1.5mm, cooking time 3min, cooking pressure 0.2MPa.

[0088] (2) Weigh 300g of pork tenderloin, add 2g of edible salt, 10g of cooking wine, 3g of starch and marinate for 10 minutes, wash and shred 40g of winter bamboo shoots, 20g of carrot, shred 20g of soaked fungus, a...

Embodiment 3

[0094] An instant noodle has an integrated layered structure, wherein the upper layer is stir-fried Kung Pao chicken layer seasoning block with a thickness of 1.5 cm, and the lower layer is noodle cake with a thickness of 4.5 cm.

[0095] The preparation method of the instant noodles of the present embodiment comprises the following steps:

[0096] (1) The noodle raw material has the following components by weight: 70 parts of wheat flour, 30 parts of potato modified starch, 5 parts of gluten, 36 parts of water, 1.5 parts of salt, 0.4 part of disodium hydrogen phosphate, 0.02 parts of konjac fine powder part, curcumin 0.1 part; kneading time 12min, noodle thickness 1.0mm, width 1.7mm, cooking time 3min, cooking pressure 0.2MPa.

[0097] (2) Weigh 250g of chicken breast, cut it into 1.0cm×1.0cm×1.0cm blocks; weigh 5g of pepper, 50g of eggs, 10g of cooking wine, 20g of starch, put them in a bowl and stir with the chicken breast Evenly; add 20g of salad oil to the wok and heat t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com