A recovery method for lithium iron phosphate material

A technology of lithium iron phosphate and a repair method, which is applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve problems such as long recycling process, and achieve the effect of avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Collect positive scraps from the coating and cutting process, and heat them step by step with an inert gas in a heating furnace with a gas collection device. The temperature is first raised from room temperature to 100°C at a rate of 5°C / min, and after holding for 1 hour, the temperature is changed from 100°C to 400°C at a rate of 5°C / min, heating and holding for 1.5 hours, the gas released during heating and holding is collected and absorbed by the gas collection device, and 1.0mol / L gas collection liquid sodium hydroxide solution is used to eliminate gas toxicity . The electrode material containing acetylene black that can be directly used is obtained after the aluminum foil on the heated positive electrode scrap is separated from the electrode material.

Embodiment 2

[0040] In the battery production process, the defective batteries in the formation stage are used as raw materials. After discharge and disassembly, the positive electrode pieces of the disassembled lithium-ion batteries after discharge treatment are cut into pieces, and the inert gas is placed in a heating furnace with a gas collection device. Heating step by step under protection, first the temperature is raised from room temperature to 90°C at a rate of 5°C / min, and after 1.5 hours of heat preservation, the temperature is raised from 90°C to 450°C at a speed of 5°C / min, heated and kept for 1 hour, and heated and kept The gas released during the process is collected and absorbed by the gas collection device, and 1.5mol / L gas collection liquid sodium hydroxide solution is used to eliminate gas toxicity. After the aluminum foil on the heated electrode sheet is separated from the electrode material, the electrode material containing acetylene black that can be used directly is o...

Embodiment 3

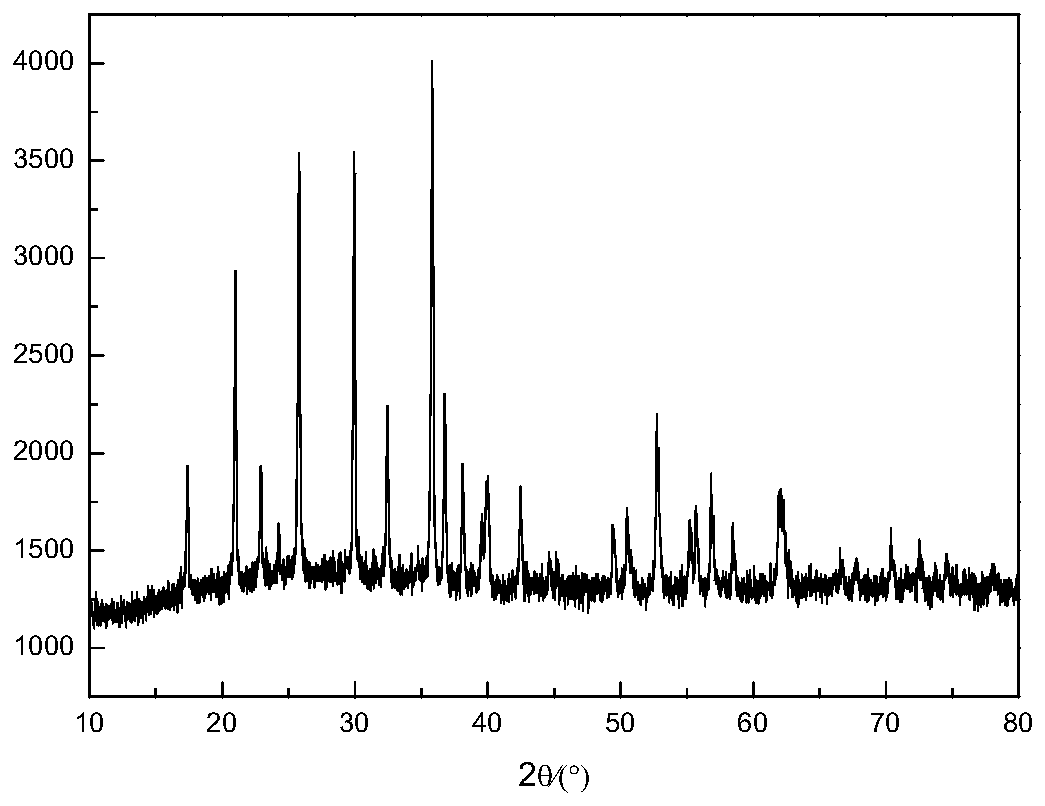

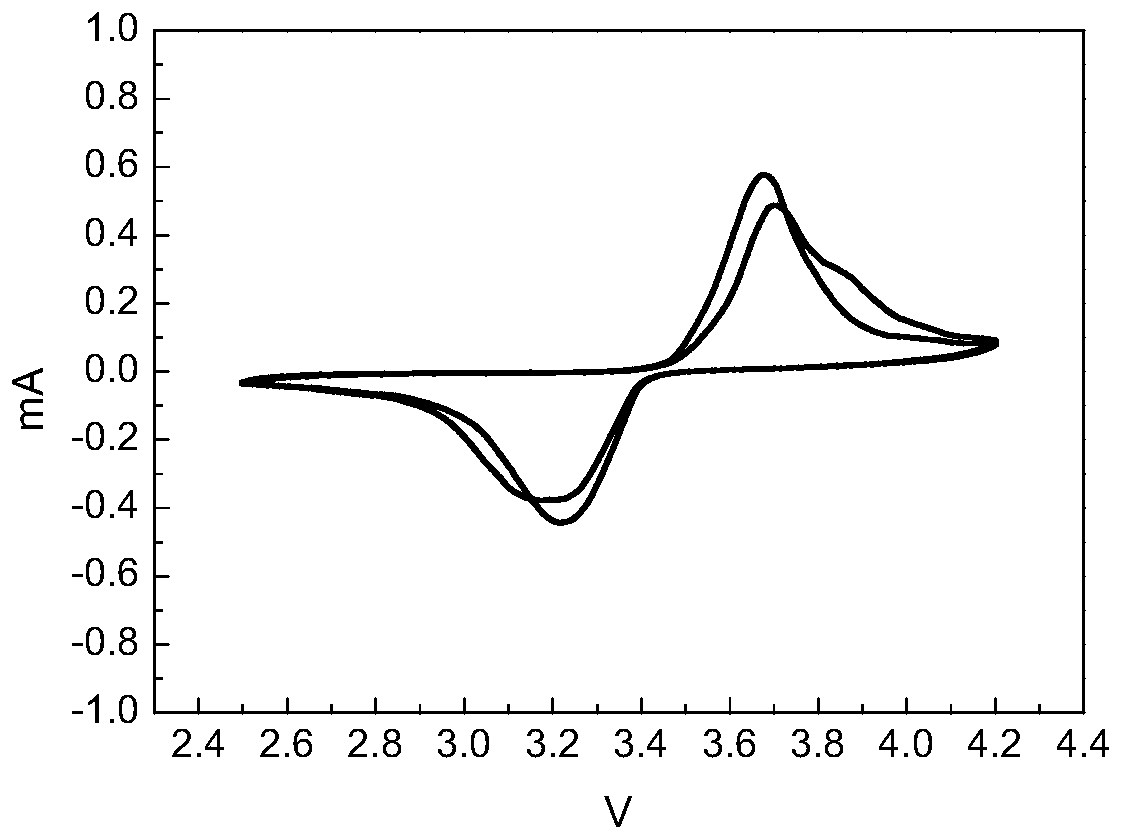

[0042]Recycled used waste batteries are used as raw materials. After discharge and disassembly, the positive electrode pieces of the disassembled lithium-ion batteries after discharge treatment are cut into pieces, and heated step by step in a heating furnace with a gas collection device under the protection of an inert gas. , firstly, the temperature is raised from room temperature to 90°C at a rate of 5°C / min, and after holding for 1 hour, the temperature is raised from 90°C to 400°C at a rate of 5°C / min, and kept for 1.5 hours. The gas collection device collects and absorbs, and uses 1.5mol / L gas collection liquid sodium hydroxide solution to eliminate gas toxicity. After the aluminum foil on the heated electrode sheet is separated from the electrode material, the content of each element in the material is tested by an inductively coupled plasma spectrometer (ICP). : The molar ratio of phosphorus is 1.05:1:1, calculate the molar mass of the recycled material after supplemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com