A wet-dry combined two-stage anaerobic fermentation biogas production process

An anaerobic fermentation and dry fermentation technology, applied in fermentation, waste fuel, etc., can solve the problems of low gas production efficiency, small gas production per unit volume, slow start-up, etc., to reduce energy consumption, improve material degradation rate, save The effect of reaction space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

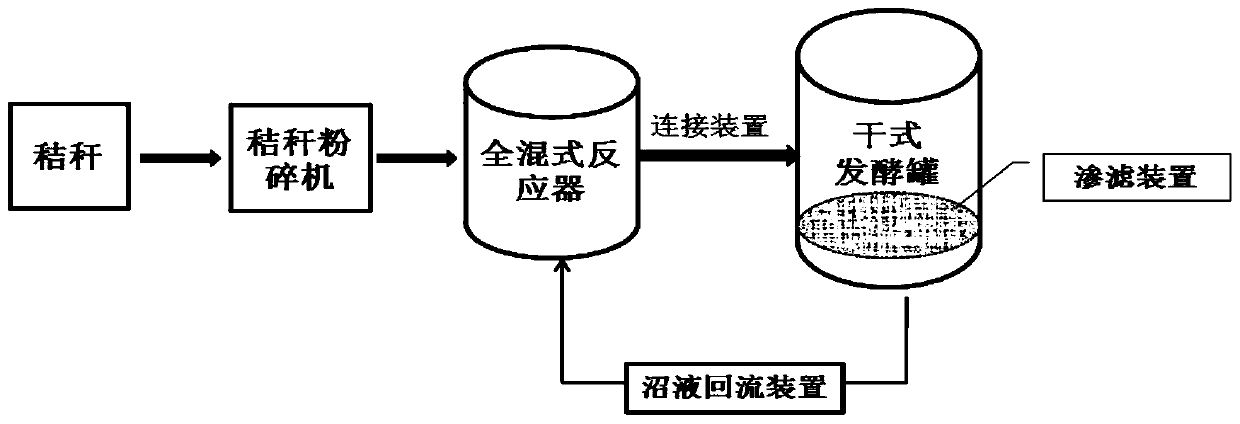

Method used

Image

Examples

Embodiment 1

[0023] The raw material and substrate of the two-stage fermentation are air-dried corn stalks from Pingdu, Qingdao, which are simply chopped before fermentation. The concentrated sludge obtained from the anaerobic activated sludge obtained from the sewage treatment plant in Sifang District, Qingdao, and centrifuged at 1000rpm for 10min was used as the inoculum.

[0024] The anaerobic fermentation experiment adopts two-stage fermentation, the first stage is wet fermentation, and the second stage is dry fermentation. The first-stage wet fermentation is mixed according to the ratio of inoculum to substrate (VS ratio) of 1:2 and added to a 250ml anaerobic fermentation bottle. The TS concentration of the substrate straw is adjusted to 4% (equivalent to 40gTS / L), and the working volume for 100ml. The pH of the fermentation mixture was adjusted to 7.5 with lye. Using CO 2 (20%) and N 2 (80%) mixed gas was aerated for 5 minutes, then sealed with a rubber stopper and an aluminum se...

Embodiment 2

[0029] The substrate of the two-stage fermentation is air-dried corn stalks from Pingdu, Qingdao, which are simply chopped before fermentation. Cow dung from the Pingdu farm was used as the inoculum for the start-up of the CSTR fermenter.

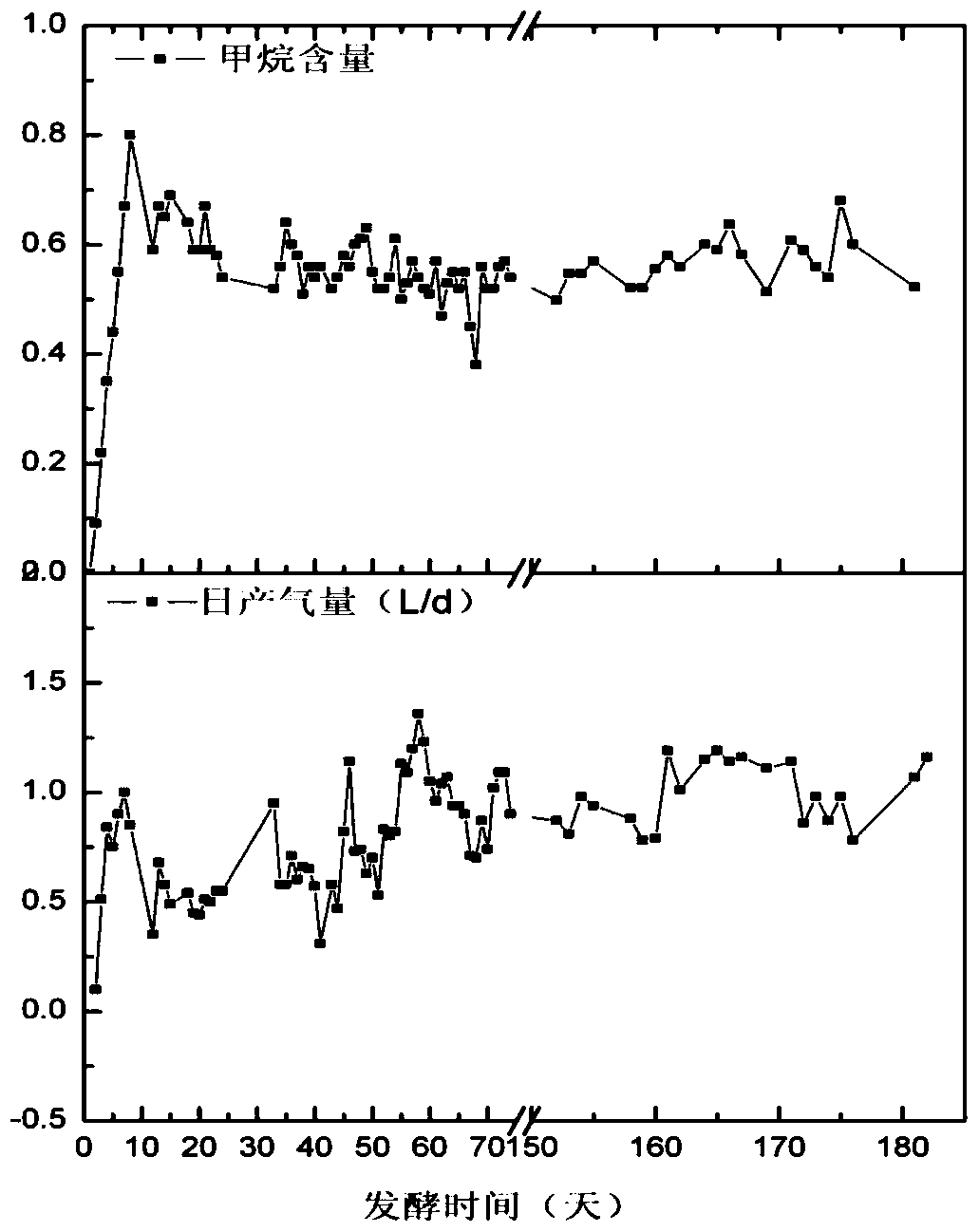

[0030] The wet stage uses a CSTR fermenter with a total volume of 5L, of which the working volume is 4L, and the HRT is set at 20 days. The solid content of the straw was 4% TS (w / v). The pH is adjusted to 7.5 at the initial stage, and the pH in the subsequent reaction system is continuously maintained between 7.0 and 7.5 without adjustment. The temperature of the water jacket circulating heating device was set at 37° C., and the stirring time was 10 minutes every 3 hours. After the reaction tank runs stably, the methane concentration in the tank is 49% to 56%. When the reaction tank system reaches stability, the average gas production rate is 980ml / d. The methane yield was 81.67L / (kgVS·d).

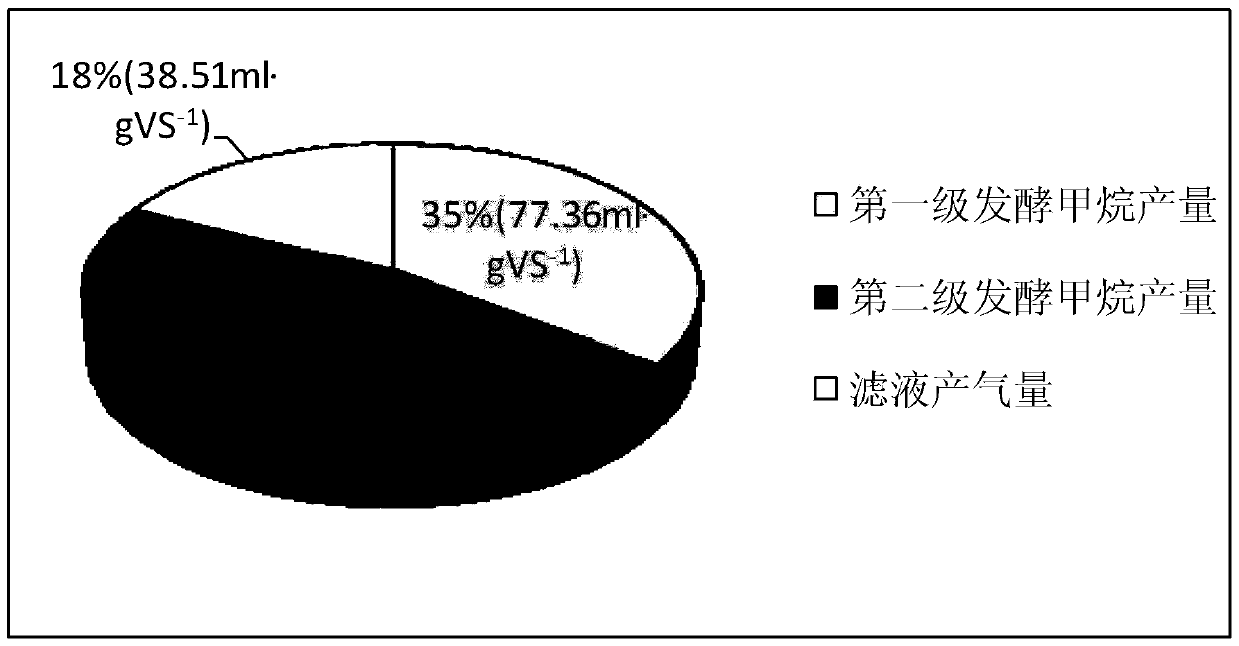

[0031] The second-stage dry fermentation ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com