Hydrogen production device

A hydrogen production device and hydrogen technology, applied in the fields of hydrogen, hydrogen/syngas production, inorganic chemistry, etc., can solve the problems of high steam heat consumption, low hydrogen production efficiency, complex structure of the hydrogen production device, etc., and achieve a simplified overall structure, Achieve the effect of recycling, reducing manufacturing cost and complexity of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

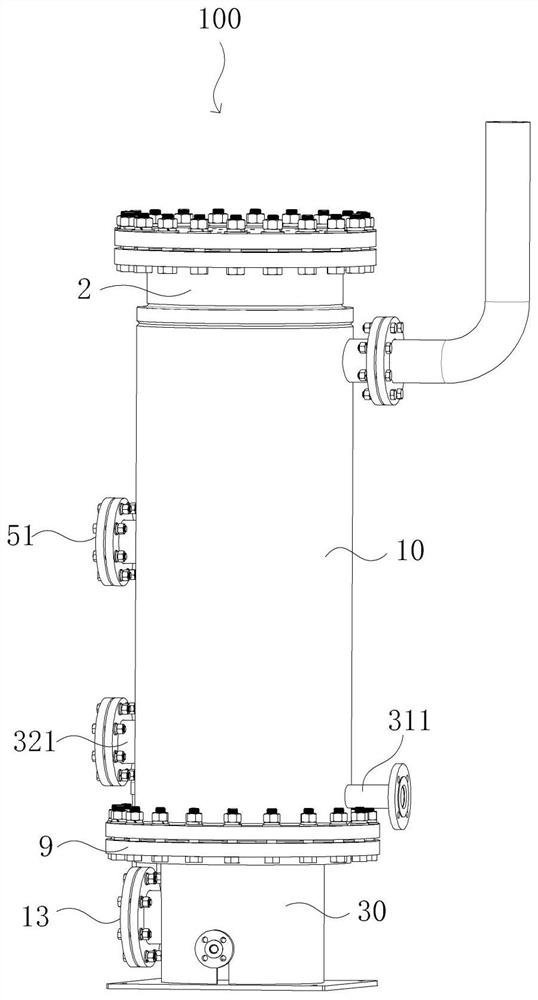

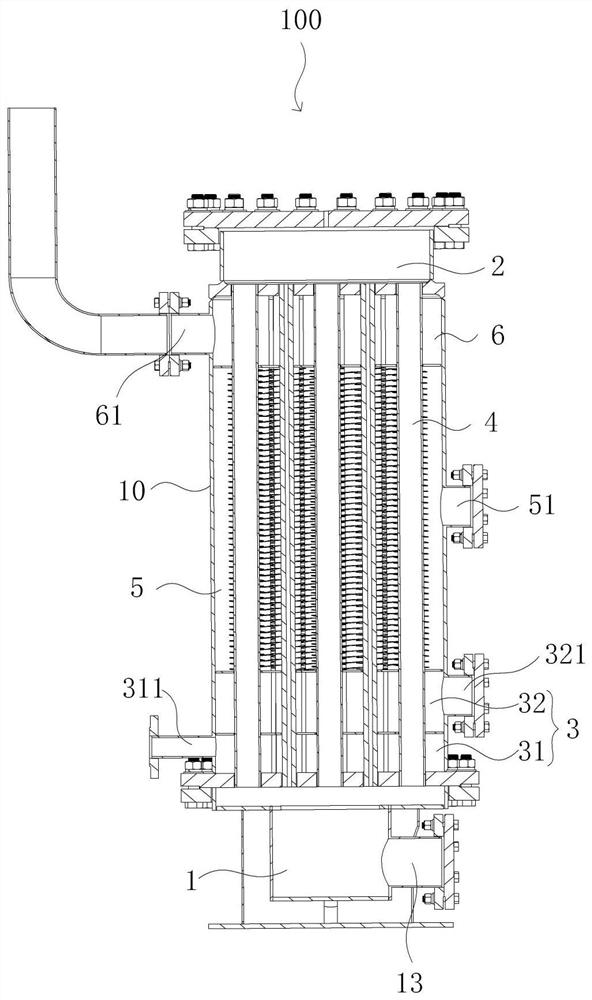

[0044] see figure 1 and figure 2 , the embodiment of the present invention provides a hydrogen production device 100 . The hydrogen production device 100 includes, for example: a housing 10 and a support base 30. The housing 10 has an accommodation space (not shown in the figure) inside, and the interior of the accommodation space is provided with a liquid accommodation chamber 1 and a hydrogen accommodation chamber 2 in sequence; Wherein, the liquid holding chamber 1 is used for holding liquid required for hydrogen production, and the hydrogen holding chamber 2 is used for holding hydrogen gas generated by the hydrogen production device 100 .

[0045] Further, the hydrogen production device 100 further includes: a heating chamber, the heating chamber is arranged between the liquid containing chamber 1 and the hydrogen containing chamber 2 .

[0046] Preferably, the heating chamber includes: an exhaust gas holding chamber 3, and / or a hot waste gas heating chamber (not shown...

no. 2 example

[0069] see Figure 8 For the improvement of the hydrogen production pipe 4 in the above first embodiment, the second embodiment of the present invention provides a hydrogen production pipe 4 . The hydrogen production pipe 4 includes, for example: a steam pipe 41 and a hydrogen pipe 42; wherein, one end of the steam pipe 41 is provided with a liquid inlet 411, and the other end is provided with a steam outlet 412; one end of the hydrogen pipe 42 is provided with a hydrogen outlet 422, and the other end A steam inlet 421 is provided.

[0070] Preferably, the hydrogen production pipe 4 can be placed vertically, or placed horizontally, or placed along other angles; when placed vertically, the hydrogen pipe 42 is positioned above the steam pipe 41 in the vertical direction, and the steam pipe 41 can communicate with the hydrogen pipe 42; When the steam pipe 41 communicates with the hydrogen pipe 42, the corresponding steam inlet 421 communicates with the steam outlet 412; when pla...

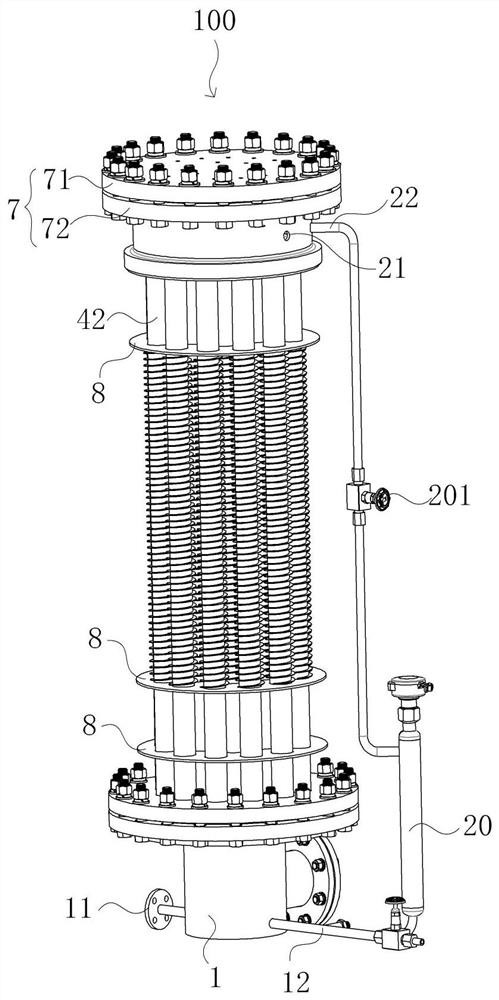

no. 3 example

[0075] The third embodiment of the present invention further provides a pipeline system 90 on the basis of the hydrogen production device 100, and the pipeline system 90 includes: a pipeline 40, a plate heat exchanger 50, a cooling fan 60 and a support part 70; Among them, the pipeline 40 is connected to the hydrogen production device 100, the plate heat exchanger 50 and the cooling fan 60 are arranged on the pipeline 40, and the support part 70 is arranged under the pipeline 40, the plate heat exchanger 50 and the cooling fan 60, for supporting the hydrogen production device 100.

[0076] preferred, see Figure 9-Figure 11 , the pipeline 40 includes: a hydrogen pipeline 401, an exhaust gas pipeline 402, a pump inlet pipe 403, a pump outlet pipe 404, and an air pipeline 406; wherein, one end of the hydrogen gas pipeline 401 is connected to the hydrogen gas connection port 21, and the other end is connected to the first hydrogen gas pipeline 401a, The hydrogen pipeline 401 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com