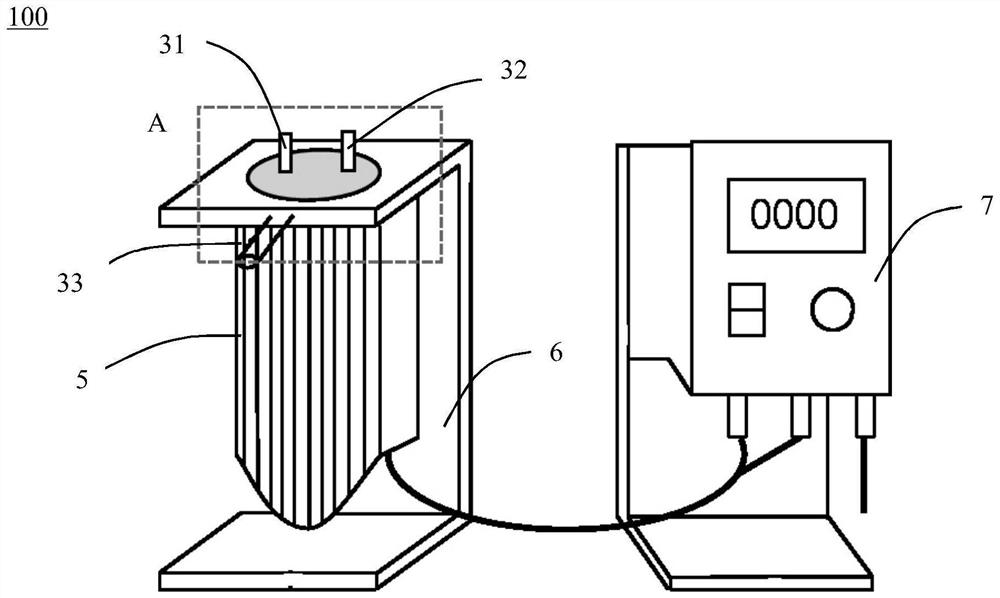

High-mixing type continuous rotary reactor and method for preparing aluminum salt lithium adsorbent by using high-mixing type continuous rotary reactor

A rotary reactor, high-mixing technology, applied in chemical/physical/physical-chemical stationary reactors, chemical instruments and methods, adsorbed water/sewage treatment, etc., can solve problems such as fluid turbulence limitation and insufficient micro-mixing , to achieve the effect of stable properties, good lithium adsorption performance and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0047] The first step, preparation of lithium-aluminum mixed solution and lye

[0048] Aluminum chloride (56 g, 0.42 mol) and lithium chloride (7 g, 0.16 mol) were dissolved in 500 mL of deionized water with Al 3+ The concentration is 0.84mol / L, Li + The concentration is 0.33mol / L. The solution was placed on a heating and stirring table and stirred for half an hour, and then sonicated for 60 min in an ultrasonic apparatus at 75° C. to ensure adequate mixing and uniformity to obtain a lithium-aluminum mixed solution.

[0049] Place 320g of sodium hydroxide in 1L of deionized water to prepare 8M sodium hydroxide lye.

[0050] The second step is to mix the reaction

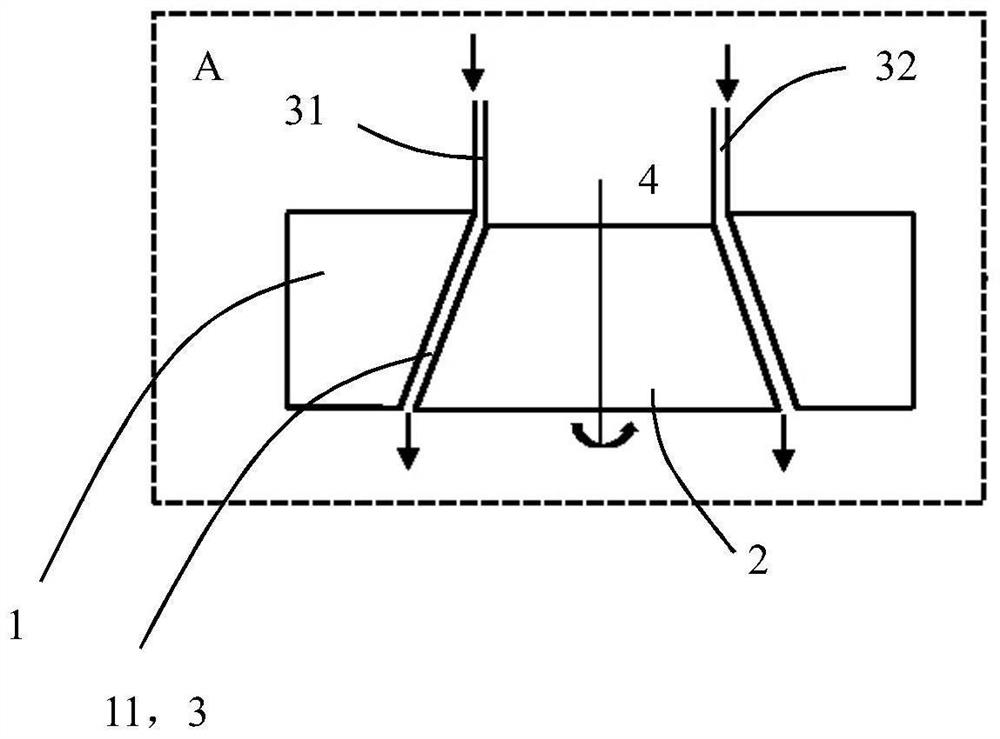

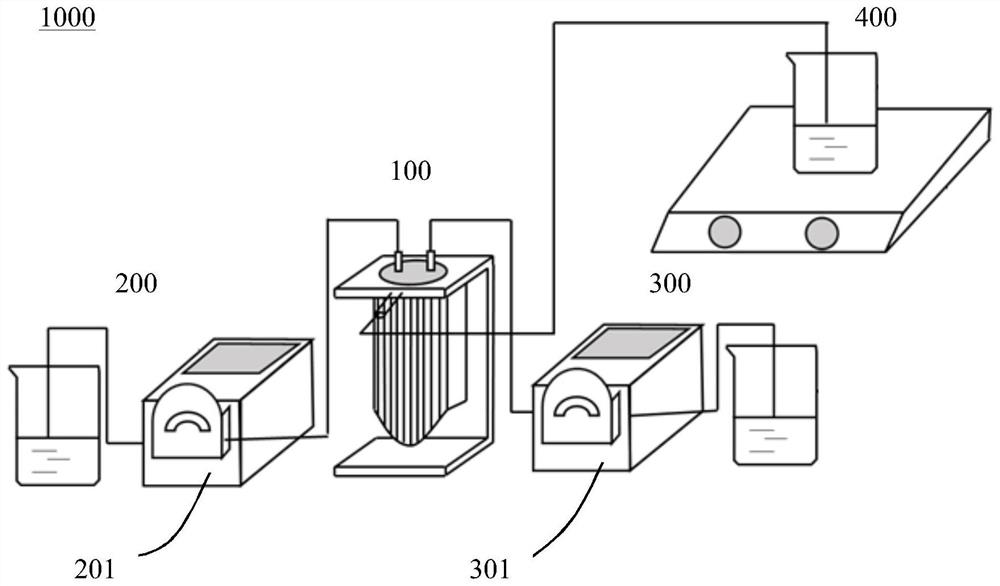

[0051] The 8M sodium hydroxide lye solution passes through the first feeding port 31 and the second feeding port respectively with the feed flow rate of 10.5mL / min and the lithium-aluminum mixed solution with the feed flow rate of 30mL / min under the action of the peristaltic pumps 201 and 301. 32 is pumped into t...

example 2

[0057] In this example, the steps of "preparation of lithium-aluminum mixed solution and alkali solution" are exactly the same as in Example 1.

[0058] The second step is to mix the reaction

[0059] The 8M sodium hydroxide lye solution passes through the first feeding port 31 and the second feeding port respectively with the feed flow rate of 14.5mL / min and the lithium-aluminum mixed solution with the feed flow rate of 45mL / min under the action of the peristaltic pumps 201 and 301. 32 is pumped into the high-mix continuous rotary reactor 100, the temperature of the reaction process is controlled at 20 ° C, the reaction gap is 0.2 mm, and the rotational speed of the high-mix continuous rotary reactor is controlled to 2000 rpm. An organic dispersion solution with a mass fraction of 2% polyvinyl alcohol was added, and 10 minutes after injection, the pH value of the effluent at the outlet was monitored by a pH meter, the pH value of the effluent was controlled to be 5, and the e...

example 3

[0065] In this example, the steps of "preparation of lithium-aluminum mixed solution and alkali solution" are exactly the same as in Example 1.

[0066] The second step is to mix the reaction

[0067] The 8M sodium hydroxide lye solution passes through the first feed port 31 and the second feed port 32 respectively with the feed flow rate of 18mL / min and the lithium-aluminum mixed solution under the action of the peristaltic pumps 201 and 301 with the feed flow rate of 60mL / min. Pump into the high-mix continuous rotary reactor 100, the temperature of the reaction process is controlled at 20 ° C, the reaction gap is 0.2mm, the speed of the high-mix continuous rotary reactor is controlled to 3000 rpm, and added from any feed port in the reaction space. For an organic dispersion solution with a mass fraction of 3% polyacrylamide, 10 min after injection, use a pH meter to monitor the pH value of the effluent at the outlet, control the pH value of the effluent to 5, and collect the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com