Environment-friendly intelligent early warning indoor plastic insulation wire and manufacturing method thereof

A plastic insulation and environmental protection technology, applied in the direction of insulated cables, insulated conductors, cable/conductor manufacturing, etc., can solve the problems of unreasonable insulation layer structure, large consumables per unit length, lack of early warning and prevention, etc., and achieve insulation performance The effect of good softness and softness, improved product cost performance, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

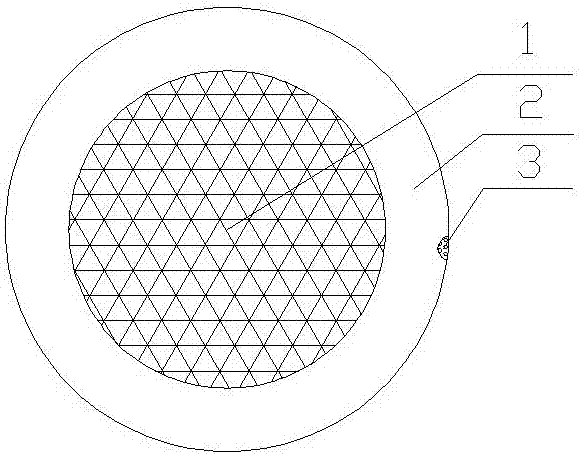

Image

Examples

Embodiment

[0024] Embodiment: The manufacture specification is ZNYJ-BV-450 / 750V 2.5 (2.5 indicates that the specification of conductor is 2.5mm2) the manufacture method of plastic insulated electric wire for environment-friendly intelligent warning room, concrete steps are as follows:

[0025] Electrolytic copper smelting, continuous casting and rolling to produce Φ8.0 mm electrolytic copper rod;

[0026] Φ8.0 mm electrolytic copper rod is drawn and annealed to make Φ1.78 mm annealed copper wire;

[0027] 3) The insulating layer and semi-conductive sign induction line injection strips are concentrically co-extruded, using a concentric co-extrusion extrusion die, the insulation thickness of 2.5mm2 is 0.8mm, and the semi-conductive sign induction line injection strip width is 1.5 mm;

[0028] 4) The outer diameter of the finished environmentally friendly intelligent early warning indoor plastic insulated wire is 3.4 mm, and the appearance is smooth and round.

[0029] After each of the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com